Reed composite material and manufacturing method thereof

A manufacturing method and technology of composite materials, applied in the field of reed wood-based panels, can solve problems such as inability to realize high value-added utilization, waste of natural resources, pollute water bodies, etc., achieve high value-added utilization, avoid pollution of water bodies, and improve resource utilization high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

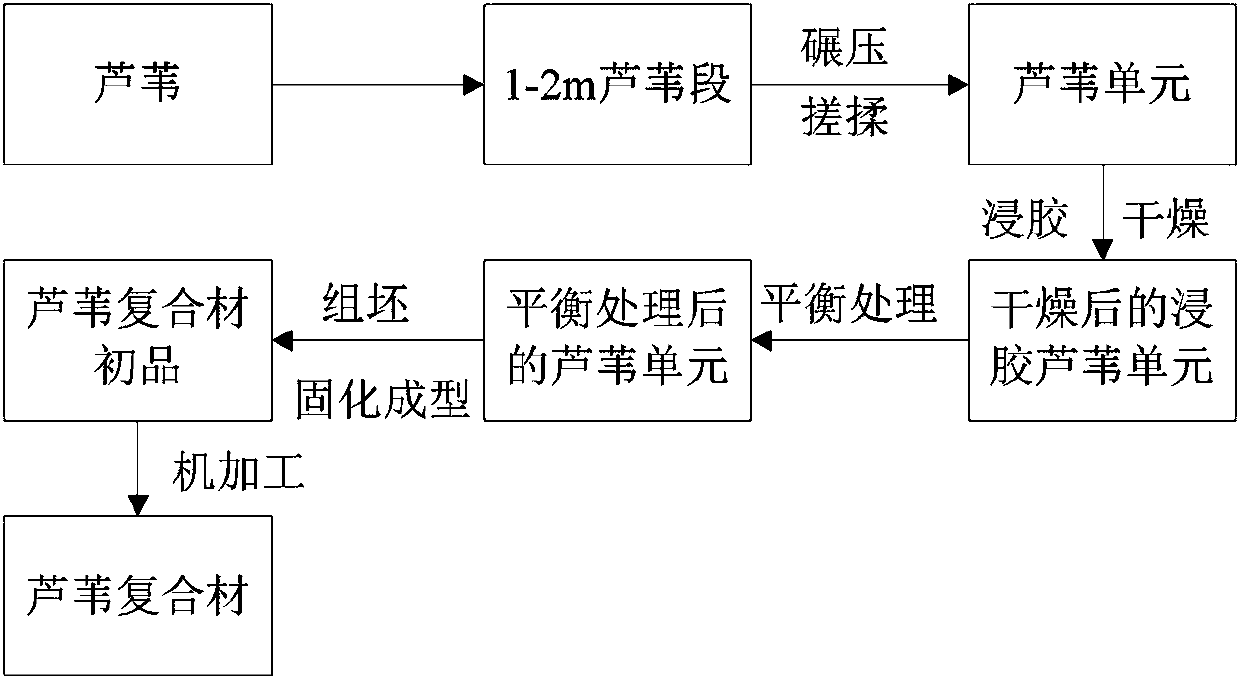

[0037] like figure 1 Shown, a kind of manufacturing method of the reed composite material of this embodiment specifically comprises the following steps:

[0038] S1: Drying of reed segments: process reeds with branches and leaves into reed segments with a length of 1.92 m using a guillotine; then use a conventional mesh belt dryer to dry them at a temperature of 100 °C, and dry them to The moisture content is about 20%, and the dried reed segments are obtained.

[0039] S2: Preparation of the reed unit: Use a flat press to roll the dried reed section, and then use a differential roller to knead it, so that the end surface of the reed section is flat, and there are continuous or discontinuous lines in the length direction. Open the longitudinal cracks so that the fluid can flow freely between the reed nodes and inside and outside the reed, so that the reed unit is obtained, such as figure 2 shown.

[0040] S3: Impregnation and drying of the reed unit: Place the crushed reed...

Embodiment 2

[0048] A method for manufacturing the reed composite material of the present embodiment, specifically comprising the following steps:

[0049] S1: Drying of the reed section: Firstly remove the branches and leaves of the reed manually, and then process the reed stalk into a reed section with a length of 1.5m by using a cross-cut saw; then dry it by superheated steam drying method, and the drying temperature is controlled at At 130°C, dry it to a moisture content of about 18% to obtain dried reed segments.

[0050] S2: Preparation of the reed unit: Roll the dried reed section with a roller press, and then knead it with a differential chain blanket, so that the end surface of the reed section is flat and continuous or discontinuous along the length direction Open longitudinal cracks in the reed so that the fluid can flow freely between the reed nodes and inside and outside the reed, and the reed unit is obtained.

[0051] S3: Impregnation and drying of the reed unit: place the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com