Roller bed preparation method for preventing pellets from being pressed in steel plate in shot blasting room

A shot blasting chamber and pellet technology, which is applied to used abrasive processing devices, manufacturing tools, metal processing equipment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] In order to make the present invention clearer, a method for installing a pull arm of a diesel locomotive according to the present invention will be further described below in conjunction with the accompanying drawings. The specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention.

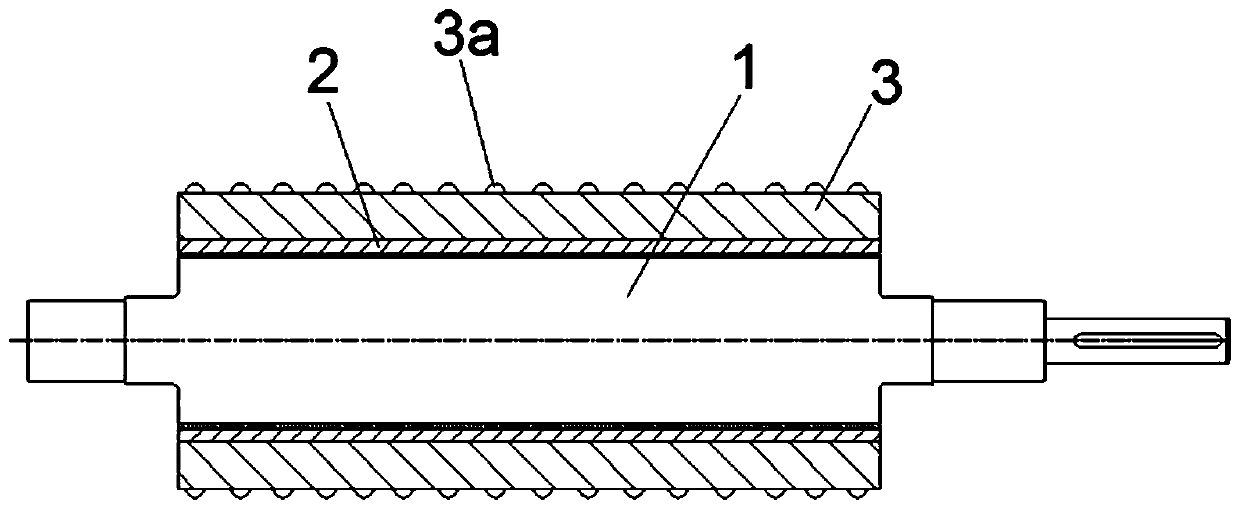

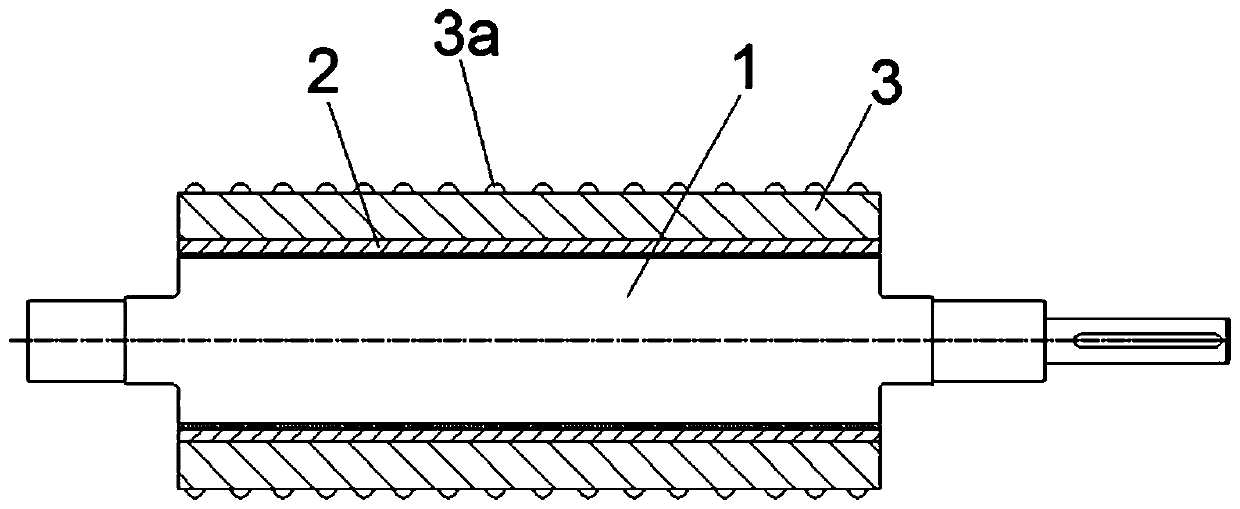

[0018] Such as figure 1 As shown, a method for preparing a roller table for preventing shot from being pressed into a steel plate in a shot blasting chamber, including a base material 1 of the roller table, is characterized in that:

[0019] There is a circle of surfacing layer 2 on the outer wall of the base material 1, and the hardness of the surfacing layer 2 is HRC45 to protect the base material;

[0020] A rubber layer 3 is arranged on the outside of the surfacing layer 2, and the hardness of the rubber layer 3 is HB450, so as to prevent pellets from being pressed into the steel plate.

[0021] see figure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com