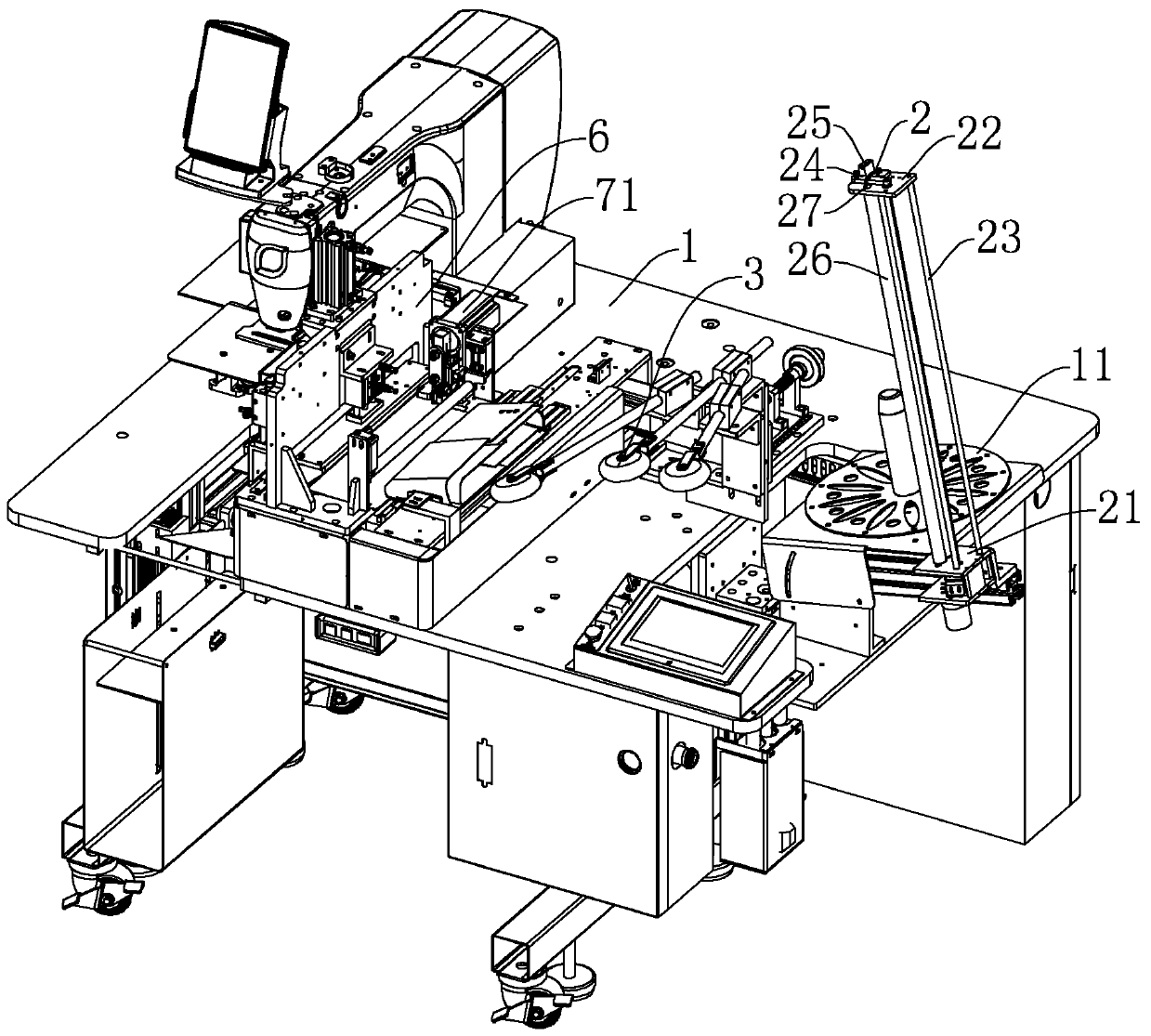

Feeding mechanism of rib collar automatic sewing machine

A feeding mechanism and sewing machine technology, applied in the direction of sewing machine components, cloth feeding mechanism, sewing equipment, etc., can solve the problems of difficult folding, large elasticity, large rib width of long rolls, etc., and achieve the effect of solving difficult conveying and folding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

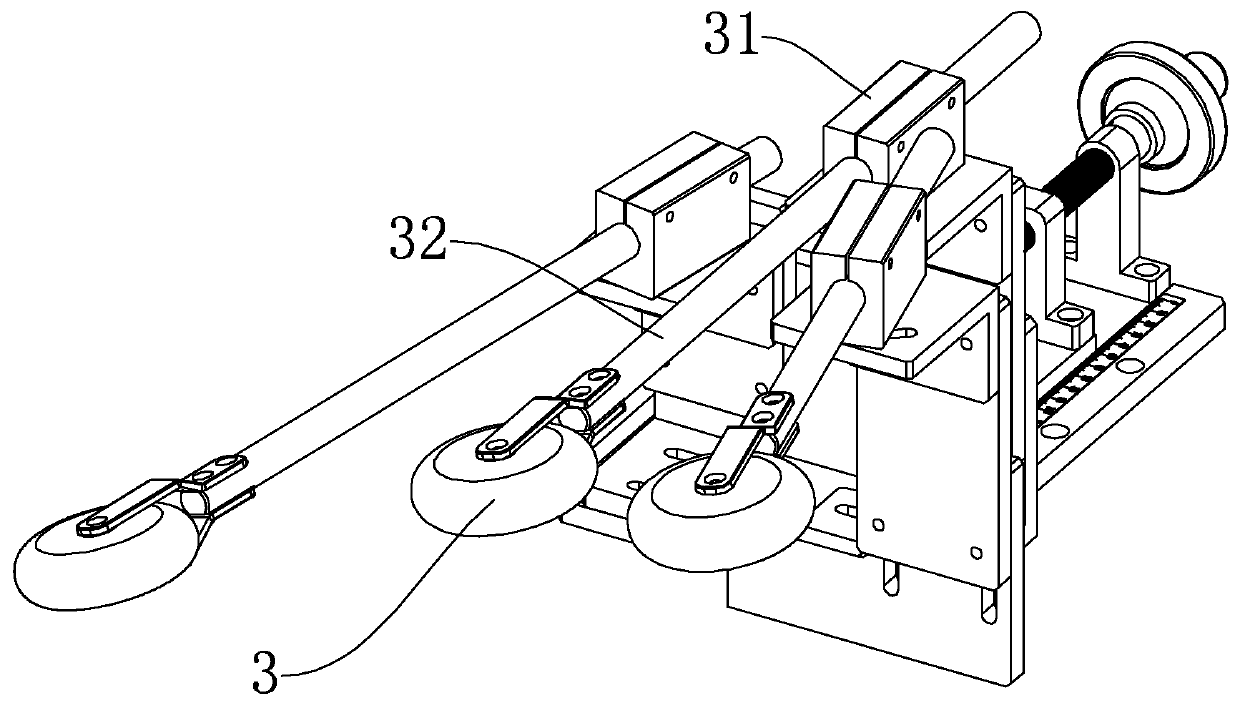

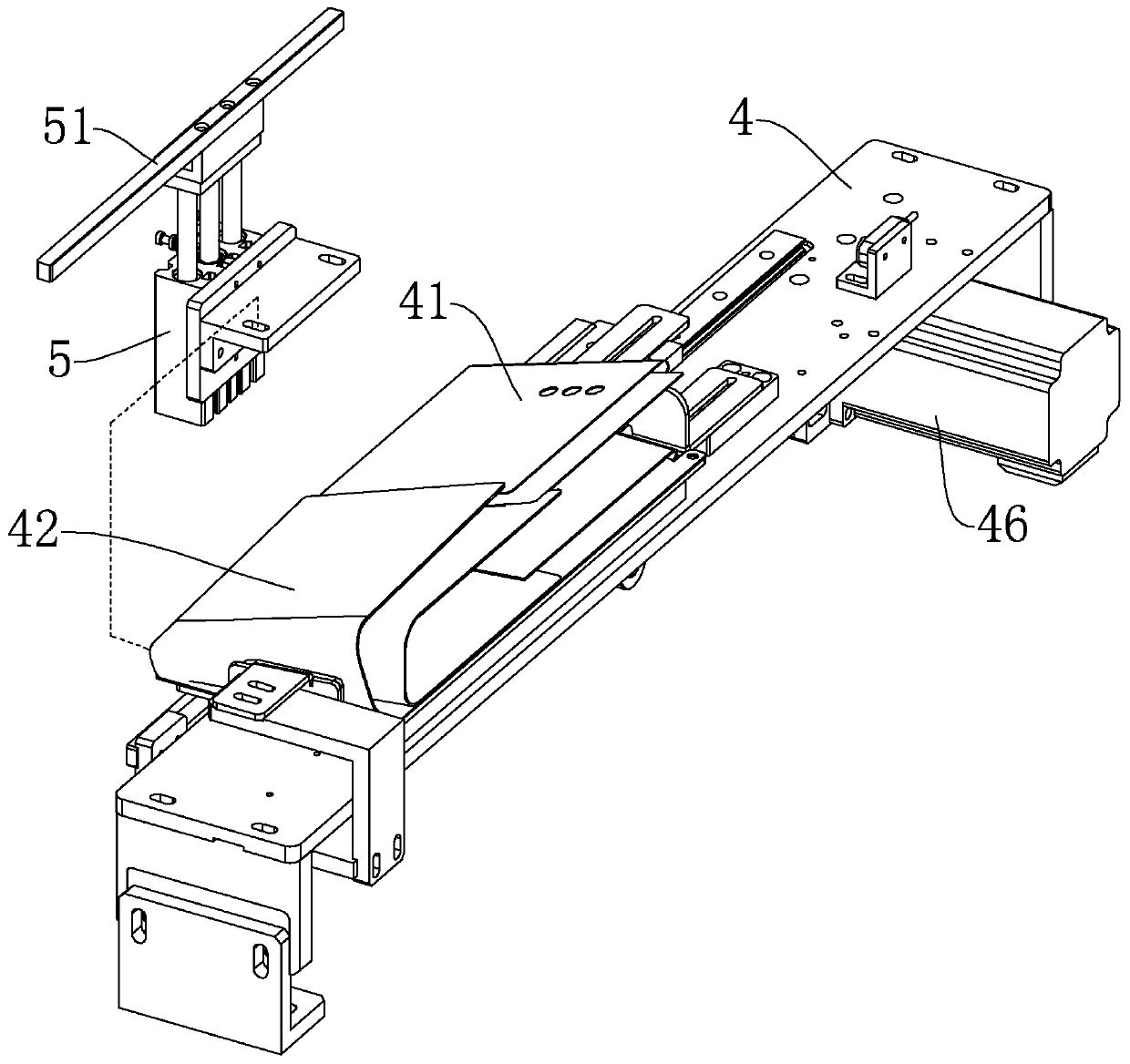

[0021] Figure 1 to Figure 6 Shown is the structural representation of the present invention.

[0022] The reference numerals therein are: frame 1, material reel 11, cloth guide rod 2, first mounting plate 21, second mounting plate 22, fixed rod 23, induction connection plate 24, inductor 25, induction rod 26 , arc-shaped chute 27, top cloth wheel 3, top cloth wheel mounting seat 31, top cloth wheel mounting rod 32, puller mounting plate 4, first puller part 41, second puller part 42, first synchronous wheel 43. The second synchronous wheel 44, puller drive synchronous belt 45, puller adjustment motor 46, drive connection plate 47, puller adjustment guide rail 48, filling cylinder 5, filling plate 51, material cutting installation bracket 6, the first passive Roller 61, the first driving roller 62, roller feeding motor 63, feeding bottom plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com