Efficient multi-freedom-degree ultrasonic vibration assisted double-sided laser machining device

A technology of ultrasonic vibration and laser processing, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problem of inability to accelerate the discharge of slag, the amplitude and frequency of vibration cannot be accurately controlled, and the stability of processing quality cannot be guaranteed. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments and illustrations.

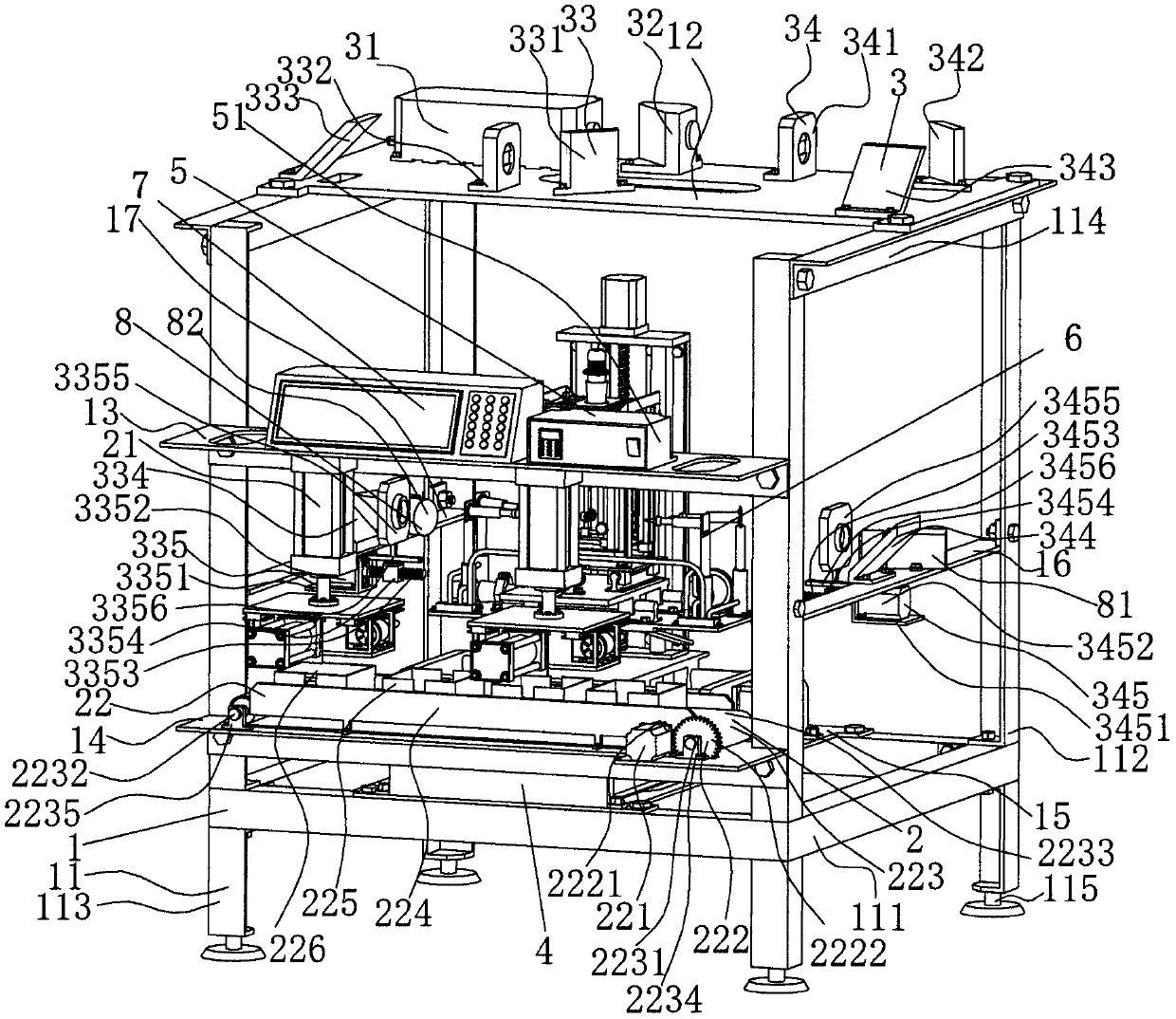

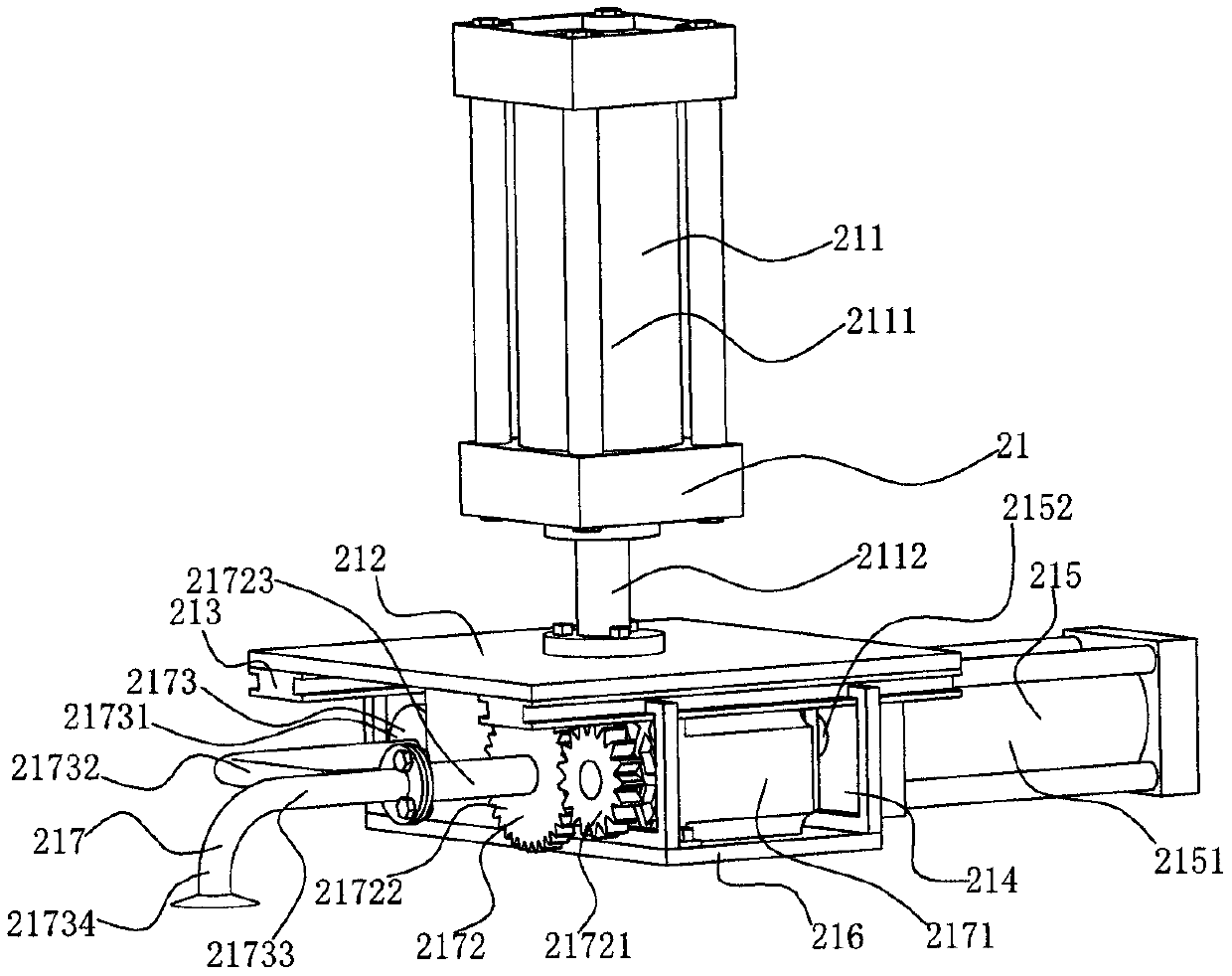

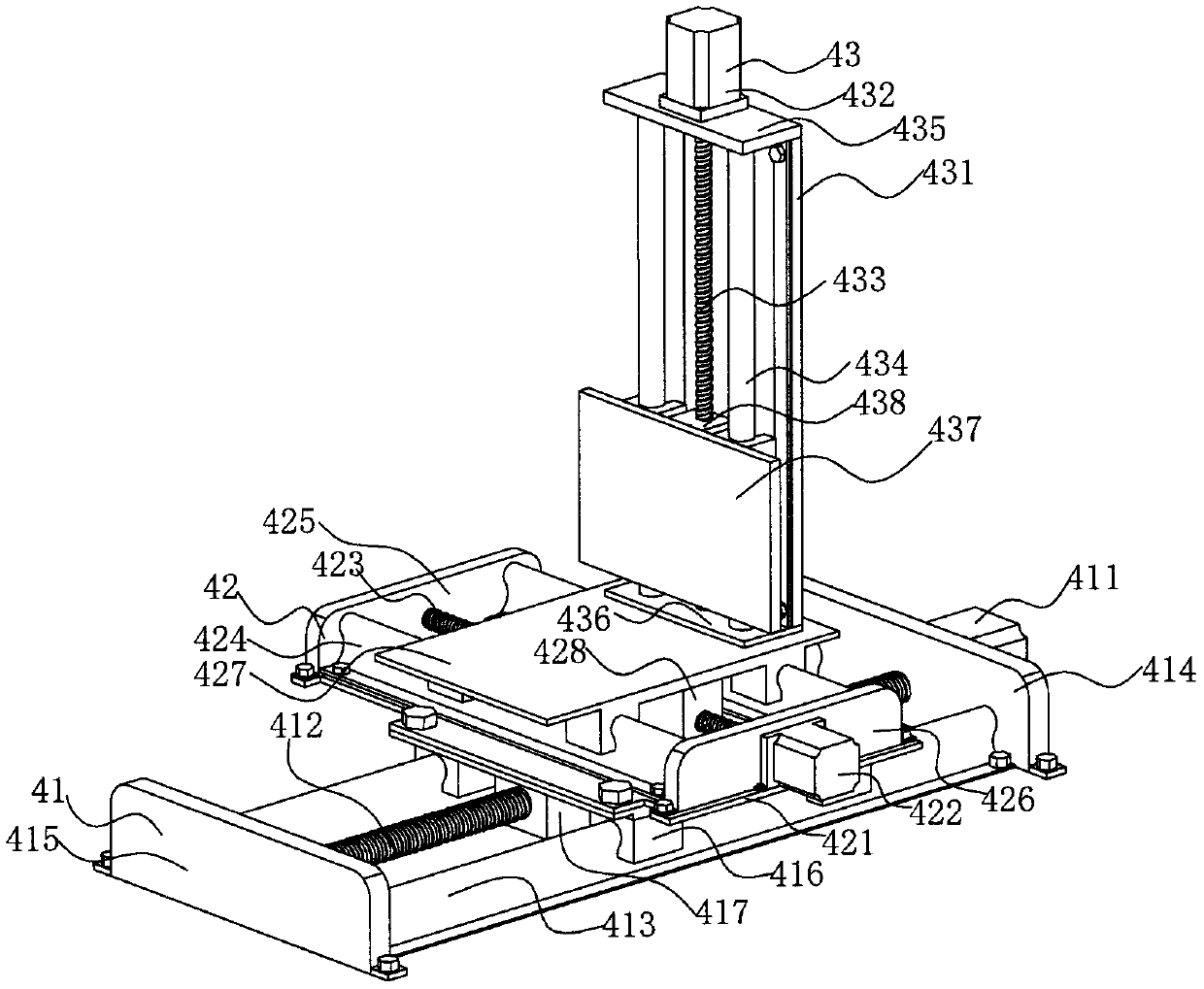

[0031] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a high-efficiency multi-degree-of-freedom ultrasonic vibration-assisted double-sided laser processing device includes a frame 1, an automatic loading and unloading device 2, a double-sided laser processing device 3, a three-degree-of-freedom moving device 4, an ultrasonic vibration auxiliary device 5, an auxiliary Air blowing device 6, controller 7, monitoring device 8, described frame 1 comprises first mounting frame 11, first mounting plate 12, second mounting plate 13, the 3rd mounting plate 14, the 4th mounting plate 15, The fifth mounting plate 16, the sixth mounting plate 17, the first mounting frame 11 includes a square steel 111, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com