Continuous scenting processing method of jasmine tea

A processing method and technology for jasmine tea, applied in the directions of tea, tea spice, tea treatment before extraction, etc., can solve the problems of increased flower volume, unstable quality, low water content of tea blanks, and the ability to absorb aroma, so as to slow down metabolism. speed, maintain the taste and flavor, and improve the effect of fresh-keeping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

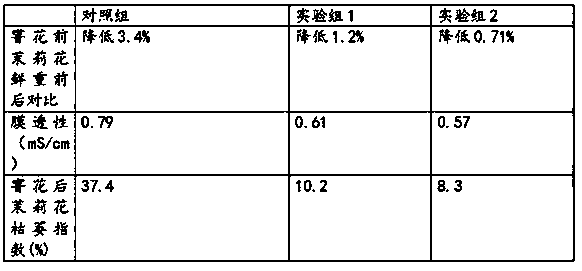

Examples

Embodiment 1

[0024] A continuous scenting processing method for jasmine tea, comprising:

[0025] (1) Treatment of jasmine: Remove the green stalks from fresh jasmine, wash them with clean water, and lay them flat in a cool place, and spray 4mol / L CaCl solution on the jasmine with a nozzle, spraying once every 3 hours;

[0026] (2) Magnolia fried tea: Add the pre-prepared tea leaves and fresh Magnolia with a weight ratio of 1:1 into the pot to fry the tea, fry for 5 minutes, the water content of the tea leaves is less than 10%, and the leaves are sieved for later use;

[0027] (3) Arrangement with flower first scenting: the fried tea leaves are mixed with flower stacks in the manner of one layer of jasmine and one layer of tea leaves. The weight ratio of jasmine and tea leaves is 2:1. The jasmine and tea leaves are separated by a screen. Fill the airtight space of stacking with ethanol gas to make the concentration of ethanol gas reach 1.8mol / L, the stacking height is less than 40cm, the s...

Embodiment 2

[0032] A continuous scenting processing method for jasmine tea, comprising:

[0033] (1) Treatment of jasmine: Remove the green stalks from fresh jasmine, wash them with clean water, and lay them flat in a cool place, and spray 6 ol / L CaCl solution on the jasmine with a nozzle, once every 4 hours;

[0034] (2) Magnolia fried tea: Add the pre-prepared tea leaves and fresh Magnolia with a weight ratio of 1:1 into the pot to fry the tea, fry for 10 minutes, the water content of the tea leaves is less than 10%, and the leaves are sieved for later use;

[0035] (3) Arrangement with flower first scenting: the fried tea leaves are mixed with flower stacks in the manner of one layer of jasmine and one layer of tea leaves. The weight ratio of jasmine and tea leaves is 2:1. The jasmine and tea leaves are separated by a screen. Fill the airtight space of stacking with ethanol gas so that the concentration of ethanol gas reaches 2.1mol / L, the stacking height is less than 40cm, the stackin...

Embodiment 3

[0040] A jasmine tea continuous scenting processing method is characterized in that, comprising:

[0041] (1) Treatment of jasmine: Remove the green stalks from the raised fresh jasmine, rinse with clean water, lay flat and stack them in a cool place, and spray 8mol / L CaCl solution on the jasmine with a nozzle, spraying once every 5h;

[0042] (2) Magnolia fried tea: Add the pre-prepared tea leaves and fresh Magnolia with a weight ratio of 1:1 into the pot to fry the tea, fry for 15 minutes, the water content of the tea leaves is less than 10%, and the leaves are sieved for later use;

[0043] (3) Arrangement with flower first scenting: the fried tea leaves are mixed with flower stacks in the manner of one layer of jasmine and one layer of tea leaves. The weight ratio of jasmine and tea leaves is 2:1. The jasmine and tea leaves are separated by a screen. Fill the airtight space of stacking with ethanol gas so that the concentration of ethanol gas reaches 3.6mol / L, the stacking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com