Dianion cobalt-based selenium sulfide and preparation method thereof

A double anion and sulfide technology, applied in the direction of active material electrodes, electrochemical generators, electrical components, etc., can solve the problems of low conductivity and poor capacity of metal sulfides, so as to improve conductivity and electrochemical performance , improve the effect of cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

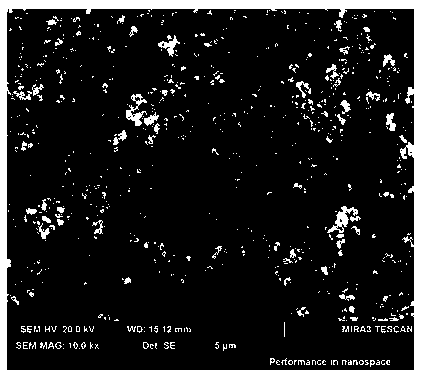

Image

Examples

Embodiment 1

[0041] (1) Weigh 1.1508 g of cobalt nitrate and dissolve it in 80 mL of the Co salt solution in methanol, weigh 1.6231 g of 2-methylimidazole and dissolve it in 80 mL of the 2-methylimidazole solution in methanol, and dissolve the 2 - Pour the methylimidazole solution into the cobalt salt solution, and leave it to age for 24 hours. After centrifugation, washing, and blast drying, the precursor is obtained;

[0042] (2) Weigh 2 mmol of selenium powder, disperse it in absolute ethanol at 0°C, add 4 mmol of sodium borohydride, and fully react until no bubbles are generated to obtain a selenium source solution;

[0043] (3) Dissolve 2 mmol of thioacetamide in 10 mL of ultrapure water to obtain a sulfur source solution; weigh 1 mmol of precursor and 30 mg of graphene oxide, disperse them in 35 mL of ultrapure water, and then add After the sulfur source solution was stirred at room temperature for 5 minutes, the selenium source solution was added dropwise. After the dropwise additio...

Embodiment 2

[0048] (1) Weigh 1.1508 g of cobalt nitrate and dissolve it in 80 mL of methanol to obtain the Co salt solution. Weigh 1.6231 g of 2-methylimidazole and dissolve it in 80 mL of methanol to obtain the 2-methylimidazole solution. After fully dissolving , pour the 2-methylimidazole solution into the cobalt nitrate solution, and leave it to age for 24 hours. After centrifugation, washing, and blast drying, the precursor is obtained;

[0049] (2) Weigh 2 mmol of selenium powder, disperse it in absolute ethanol at 0°C, add 4 mmol of sodium borohydride, and fully react until no bubbles are generated to obtain a selenium source solution;

[0050] (3) Dissolve 2 mmol of thioacetamide in 10 mL of ultrapure water to obtain a sulfur source solution; weigh 2 mmol of precursor and 40 mg of graphene oxide, disperse them in 35 mL of ultrapure water, and pour Add the sulfur source solution, stir at room temperature for 5 minutes, then add the selenium source solution dropwise, react at 180°C f...

Embodiment 3

[0054] (1) Weigh 1.1508 g of cobalt nitrate and dissolve the Co salt solution in 80 mL of methanol; weigh 1.6231 g of 2-methylimidazole and dissolve it in 80 mL of 2-methylimidazole solution in methanol; The 2-methylimidazole solution was poured into the cobalt nitrate solution, and left to age for 24 hours. After centrifugation, washing, and blast drying, the precursor was obtained;

[0055] (2) Weigh 2 mmol of selenium powder, disperse it in absolute ethanol at 0°C, add 4 mmol of sodium borohydride, and fully react until no bubbles are generated to obtain a selenium source solution;

[0056] (3) Dissolve 2 mmol of thioacetamide in 10 mL of ultrapure water to obtain a sulfur source solution; weigh 2 mmol of precursor and 50 mg of graphene oxide, disperse them in 35 mL of ultrapure water, add sulfur After stirring the source solution at room temperature for 5 minutes, add the selenium source solution dropwise, and react at 180°C for 16 hours after the dropwise addition. After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com