Explosive stress testing device based on multiple pulse tests

A technology of multiple pulse and stress testing, applied in the direction of measuring devices, mechanical devices, instruments, etc., to reduce the number, reduce radial vibration, and avoid premature damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail, it should be noted that the present invention is not limited to following specific embodiment, all equivalent transformations carried out on the basis of the technical solution of the present invention are all within the scope of protection of the present invention.

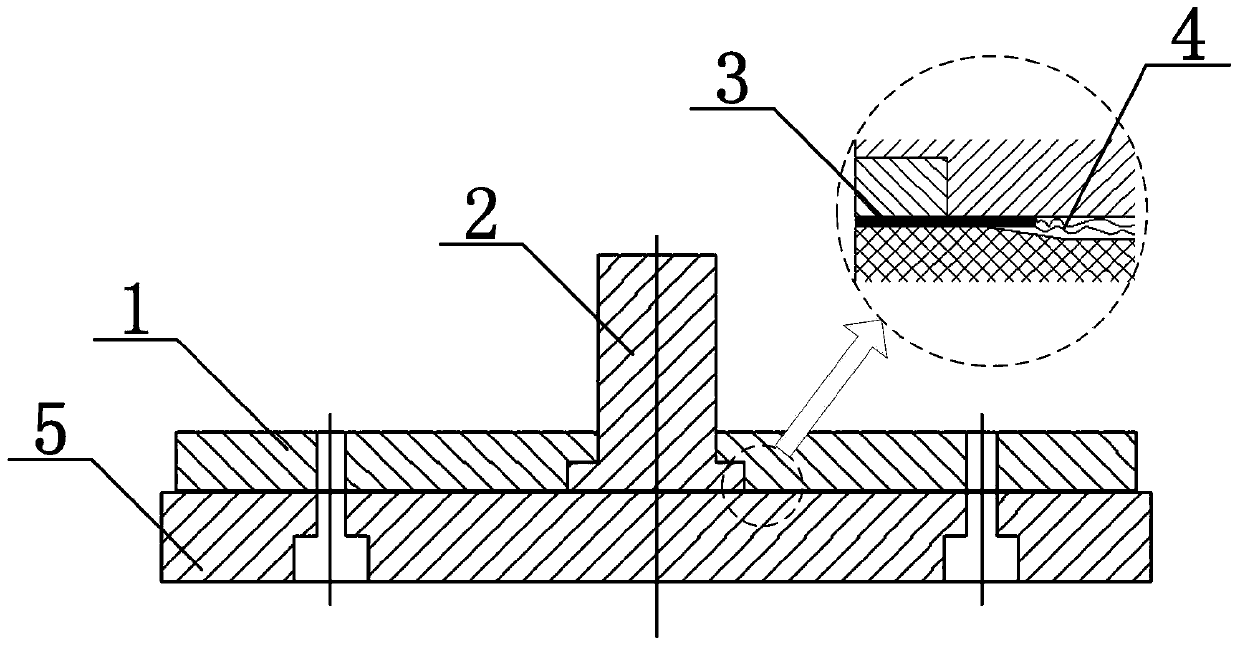

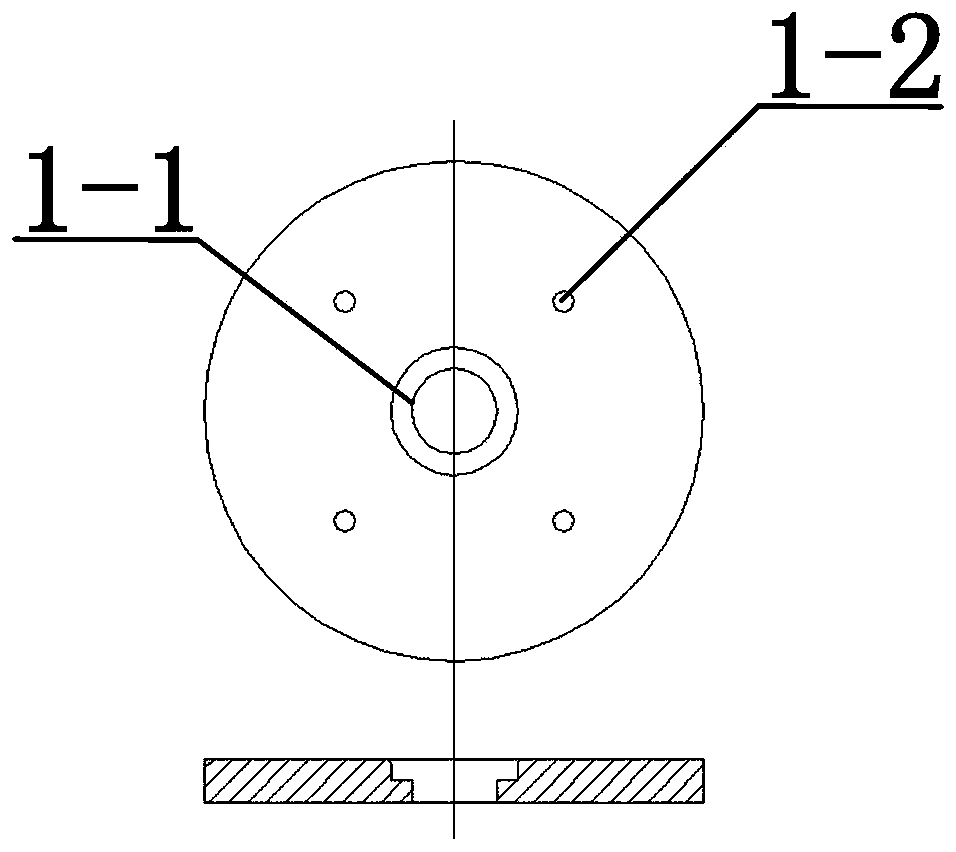

[0021] Comply with the above technical solutions, such as Figure 1-Figure 5 As shown, this embodiment provides an explosive stress test device based on multiple pulse tests, including an upper platen 1 , a table-shaped stud 2 , a manganin sensor 3 , a data transmission line 4 , and a lower plate 5 . Wherein the upper platen 1 is a circular frustum with stepped through holes 1-1 and 4 evenly distributed around the center, and the height of the stepped through holes 1-1 with smaller diameters and the height of the upper platen 1 The ratio is 1 to 2:3, and the through hole 1-2 is a standard M8 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com