Multi-stage ski-jump energy dissipation drainage system

A drainage system and energy dissipation technology, applied in the field of field engineering, to achieve the effect of collecting irrigation tail water, reducing soil loss, and good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following is a further description of the multi-stage deflected flow energy dissipation drainage system in conjunction with the accompanying drawings.

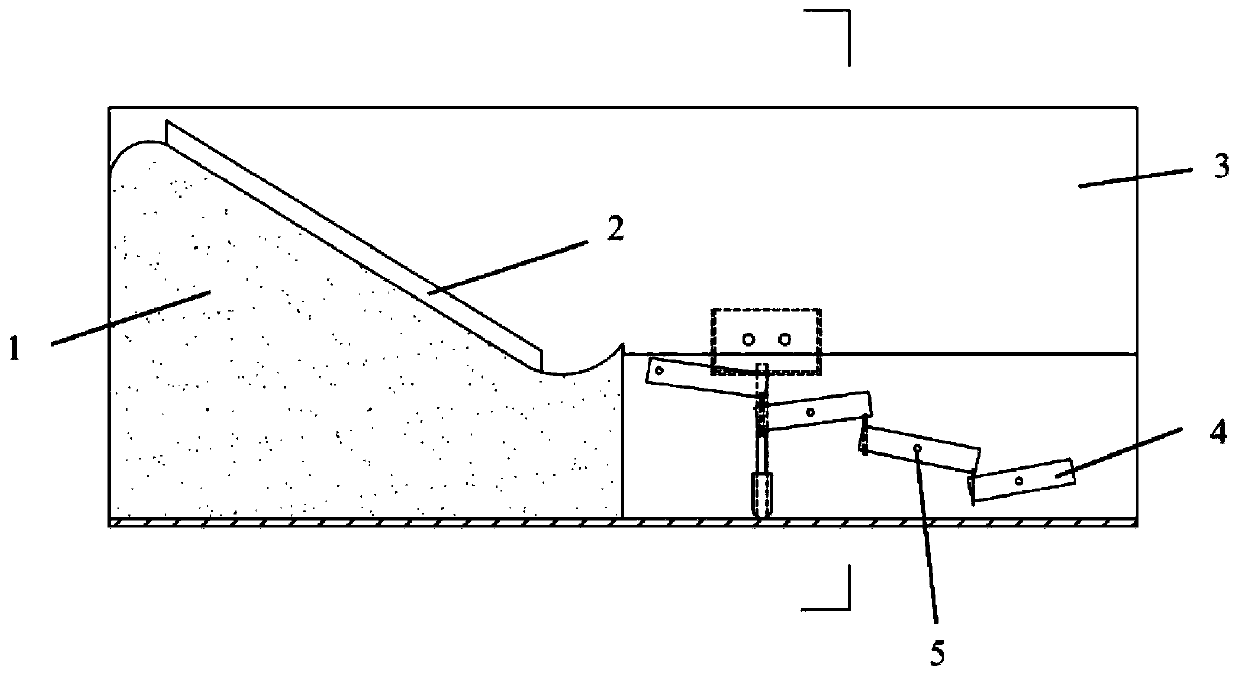

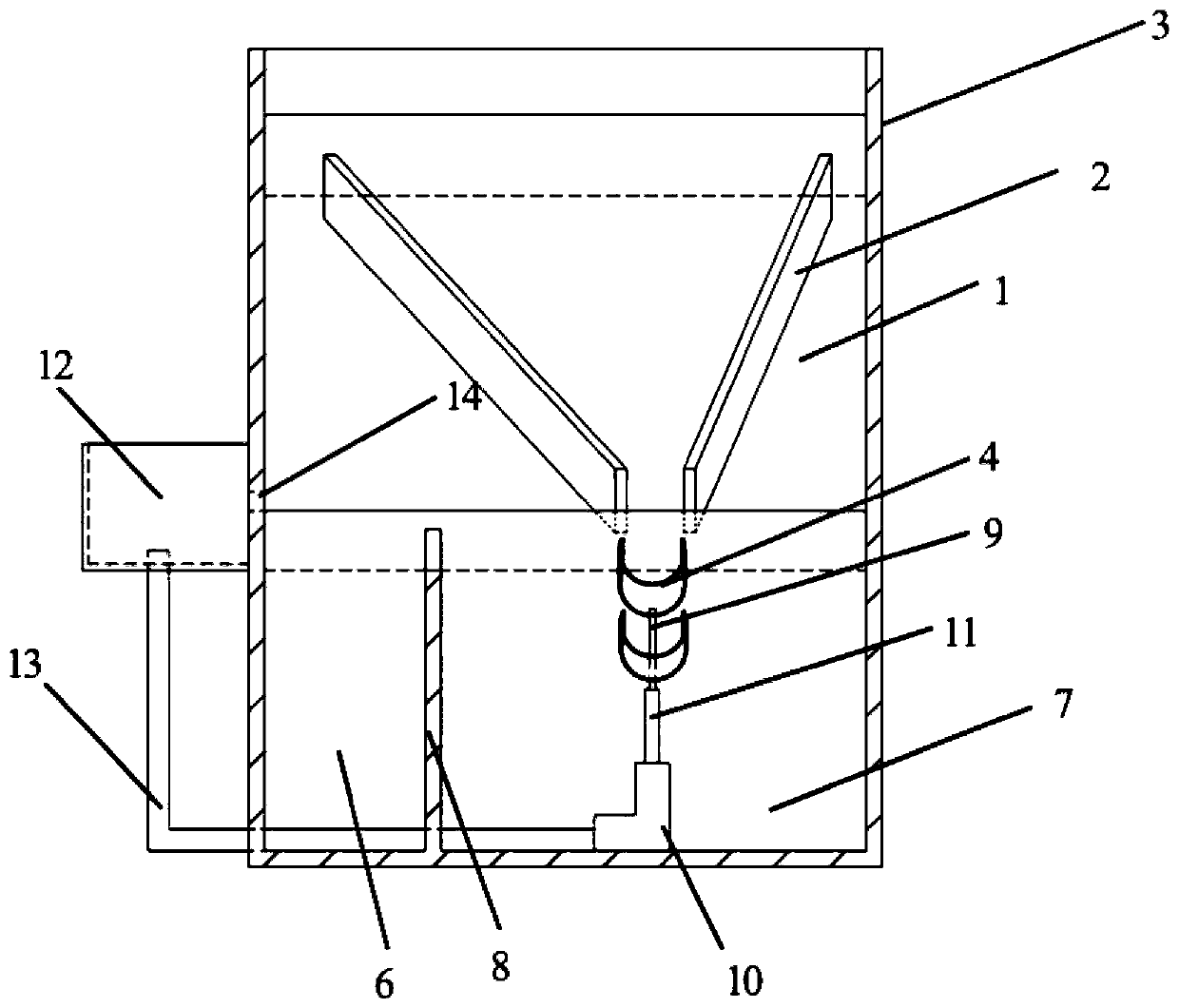

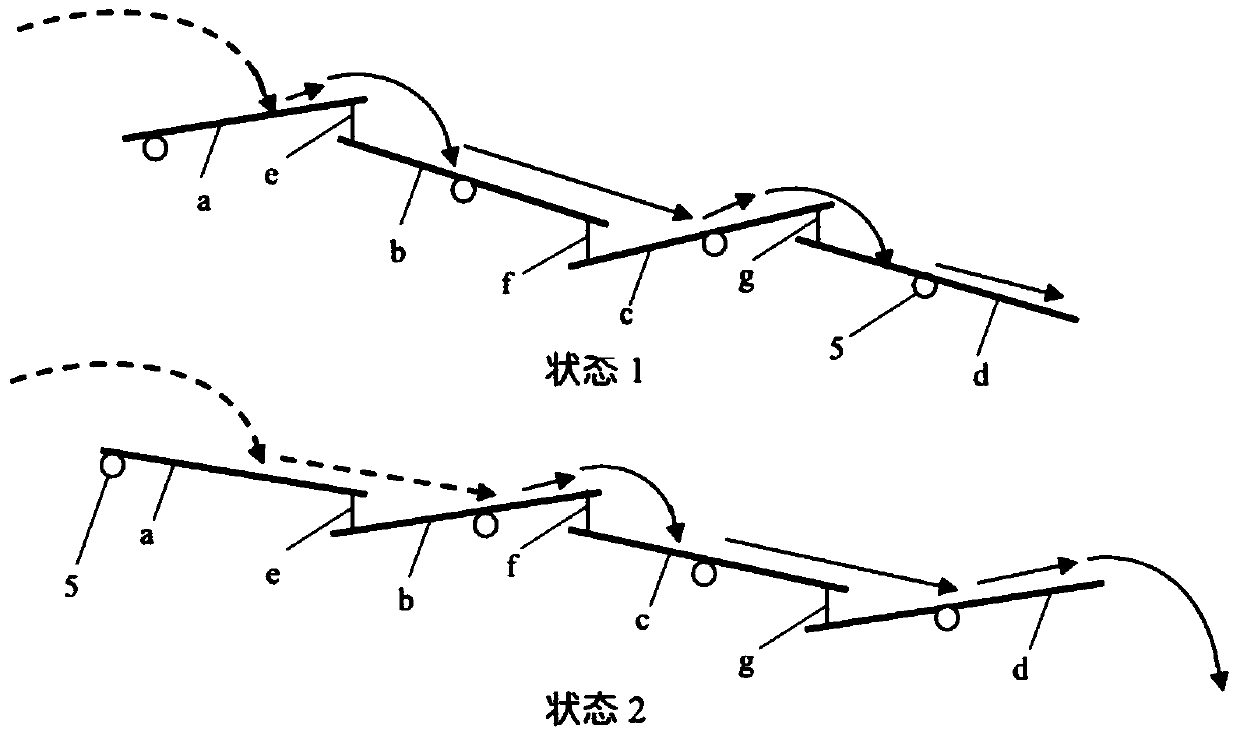

[0022] Such as Figures 1 to 3 , a multi-stage deflected flow energy dissipation drainage system, which generally includes three parts: an energy dissipation drainage channel, a field drainage system and a connecting device. Complete the collection of field tail water and discharge it into the field tail water discharge area in the energy dissipation drain, and the connection device supports the adjustment of the height of the connection shaft by the water pressure.

[0023] Such as Figure 1-3 As shown, the energy-dissipating drainage channel includes a deflector nose sill 1, a diversion wall 2, a water diversion channel wall 3, a diversion channel 4, a fixed shaft 5, a field tail water discharge area 6, an energy dissipation tail water discharge area 7, and partitions wall 8. The connecting device comprises a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com