Drafting system and drafting system unit for a spinning machine

A drafting device and spinning machine technology, applied in spinning machines, drafting equipment, textiles and papermaking, etc., can solve problems such as large operating force, achieve reliable force transmission and operating force, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

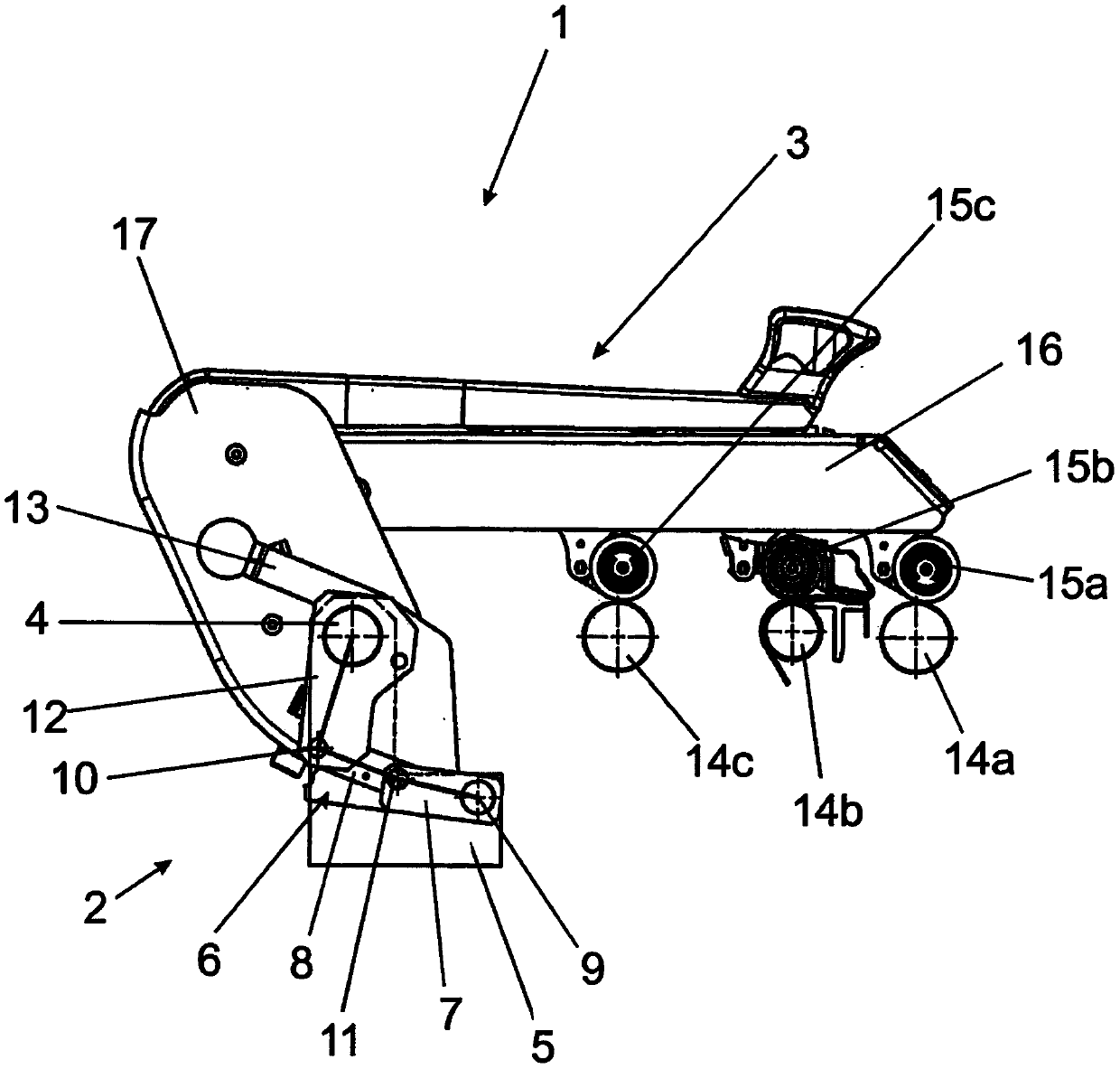

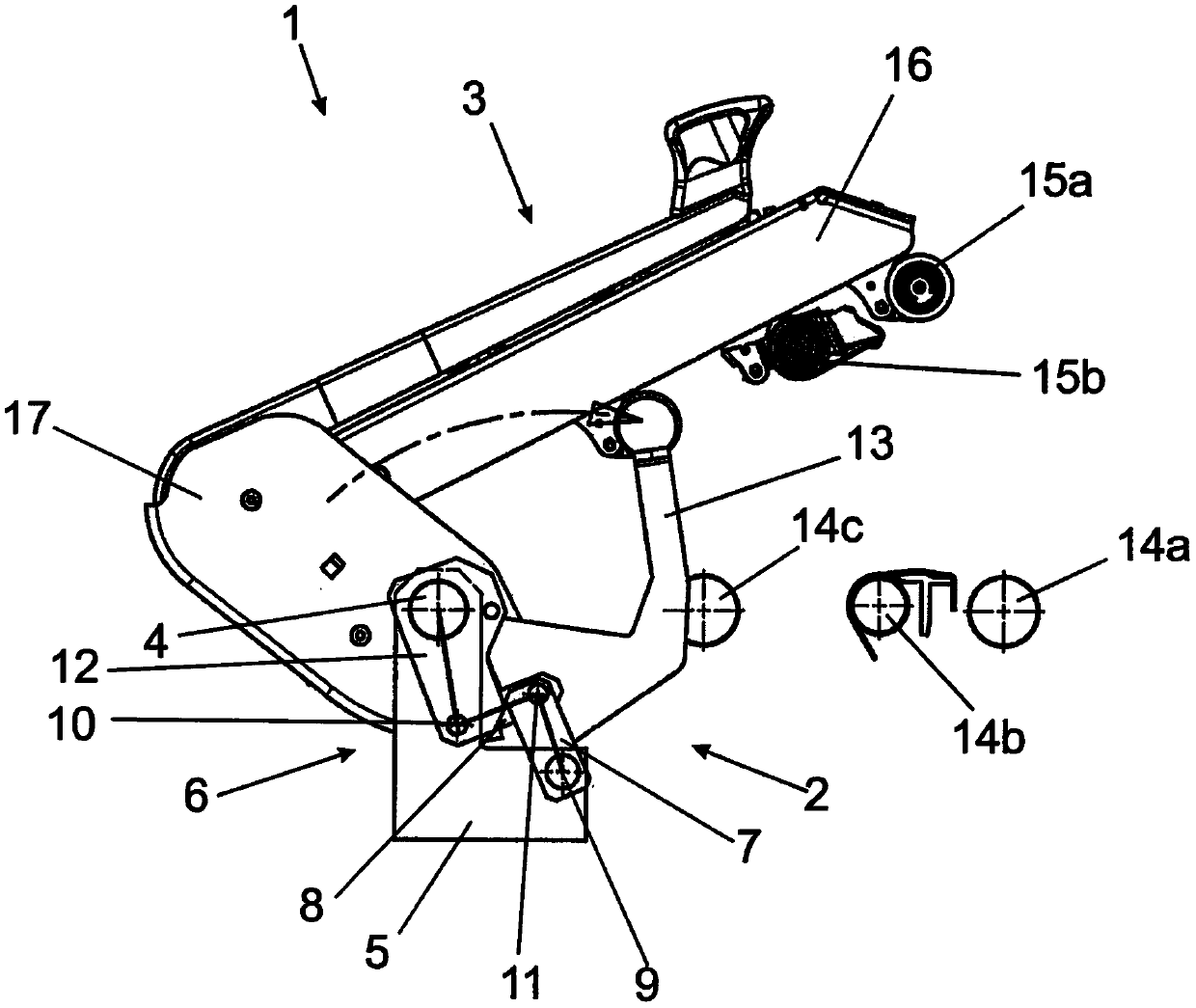

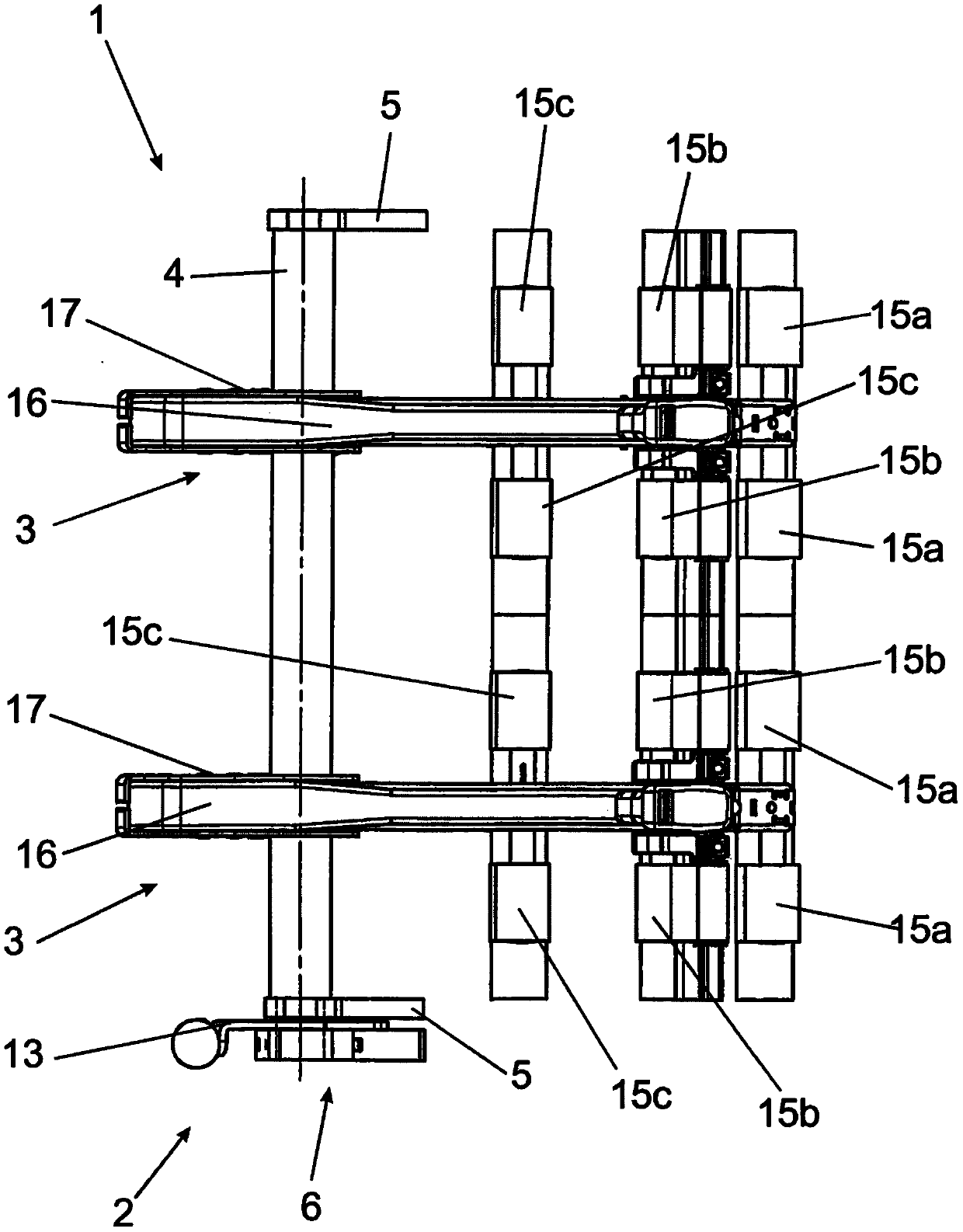

[0039] Spinning machine not shown here such as figure 1 The drafting unit 1 shown is used for the pressure rollers 15a, 15b, 15c and other lower rollers 14a, 14b, 14c which are arranged on the support arms 16 of the pressure saddle 3 of the drafting device which are not shown here. Fiber slivers are drawn between them. To this end, the roller pairs each consisting of a lower roller 14a, 14b, 14c and a pressure roller 15a, 15b, 15c have different rotational speeds that increase in the conveying direction, in order to achieve fiber sliver drafting in the region between the roller pairs. stretch.

[0040] In the exemplary embodiment shown, the drafting unit 1 has two pressurized saddles 3 arranged parallel to each other on the holding rod 4 and each having a support arm 16, each of which has three by two The pair of pressure rollers 15 a , 15 b , 15 c has an axis of rotation extending perpendicularly to the longitudinal axis of the associated support arm 16 . At this point eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com