Accumulator and hydraulic control system, machine and shifting method having the accumulator

A technology of control system and accumulator, which is applied in the direction of components with teeth, transmission device control, mechanical equipment, etc., can solve problems such as large impact force, vehicle vibration, machine material shaking, etc., to improve the locking ability , Comfortable shifting process, avoiding the effect of shifting impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

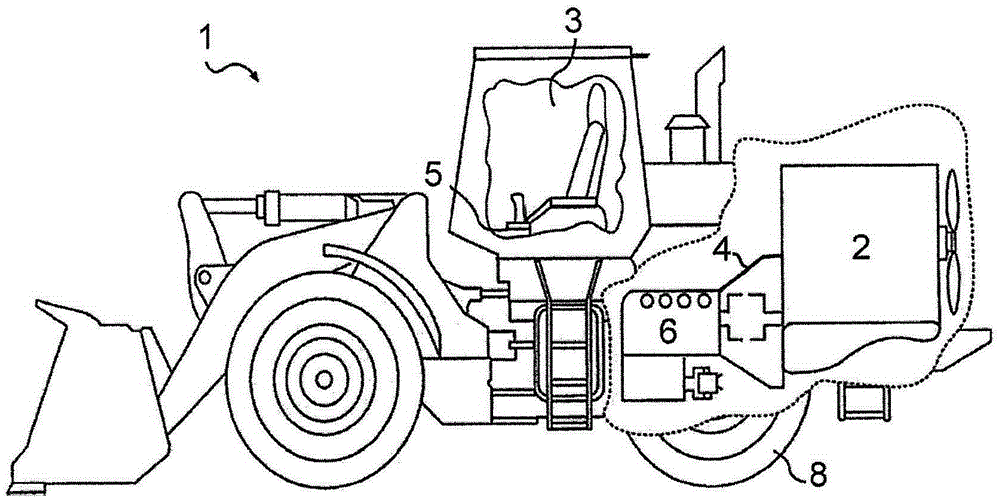

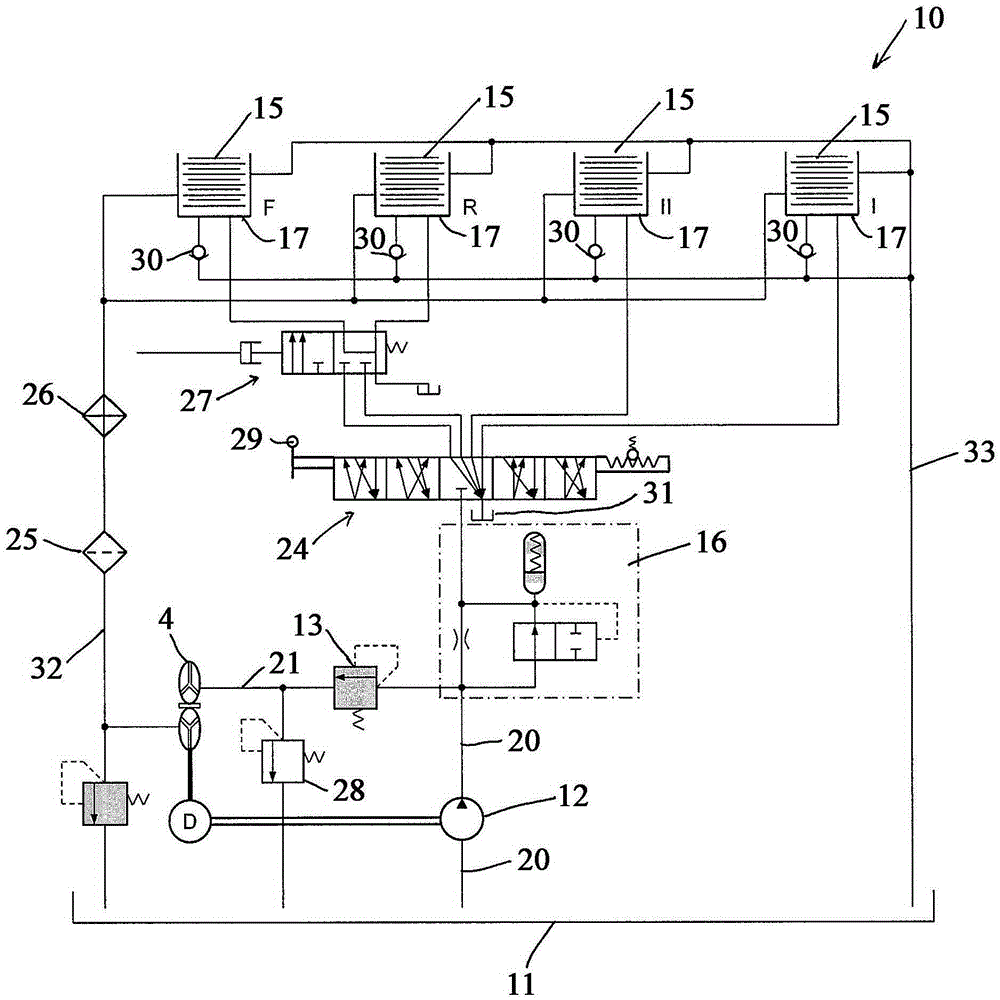

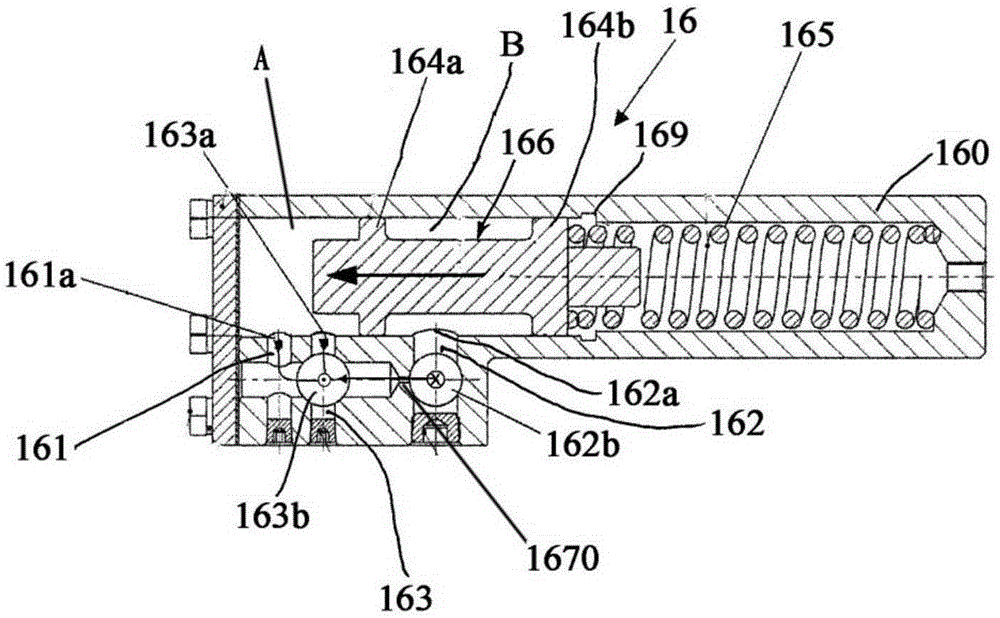

[0022] figure 1 An exemplary machine 1 is shown. The machine 1 may be a mobile machine performing certain tasks related to industries such as mining, construction, farming, transportation, or other industries known in the art. For example, machine 1 may be an earth moving machine, such as a wheel loader, off-road truck, motor grader, or any other earth moving machine. The machine 1 may also be a ship, a passenger vehicle or any other suitable work performing machine. Machine 1 may include a power source 2 , a torque converter 4 and a transmission 6 operatively connected to a traction device 8 . The machine 1 may also include an operator station 3 and one or more operator interface devices 5 for manually controlling the machine 1 .

[0023] The power source 2 can generate a power output, and can be embodied as an internal combustion engine, such as a diesel engine, a gasoline engine, a gas fuel engine, or any other type of engine known to those skilled in the art. The power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com