Seeding method and manufacturing method of czochralski silicon single crystal

A technology of Czochralski silicon and single crystal, which is applied to the seeding of Czochralski silicon single crystal. The above seeding method is used to manufacture Czochralski silicon single crystal, which can solve the lack of judgment standards and the difficulty of ensuring stable production of single crystal silicon rods, etc. problems, to achieve the effect of reducing the dependence on technical proficiency, eliminating the influence of temperature adjustment results, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

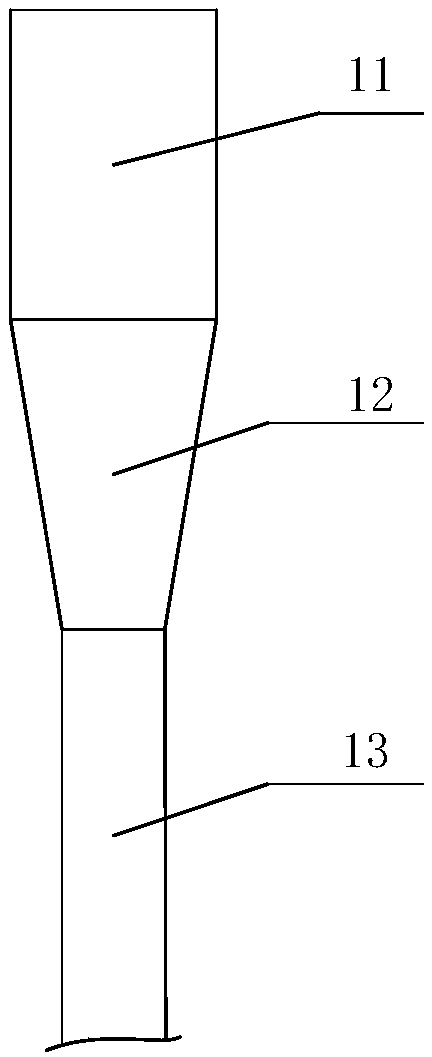

[0024] figure 1 A seeding process involved in the Czochralski silicon single crystal seeding method is shown. This seeding process can be divided into initial seeding 11 , continuous diameter reduction process 12 and post seeding 13 after continuous diameter reduction process. In the continuous shrinkage process 12, adopt the Czochralski monocrystalline silicon seeding method of the present invention, at least use the seeding speed deviation as a parameter for regulating the seeding temperature, and the seeding speed deviation is the temperature-regulating period of the seeding temperature The difference between the average seeding speed and the set seeding speed.

[0025] After the single crystal is introduced, the seeding diameter of the initial seeding 11 is usually 12-16mm. In order to eliminate the dislocations in the extracted single crystal, a continuous diameter reduction process 12 needs to be carried out. The target diameter range of diameter reduction is 5-6mm. Af...

Embodiment 2

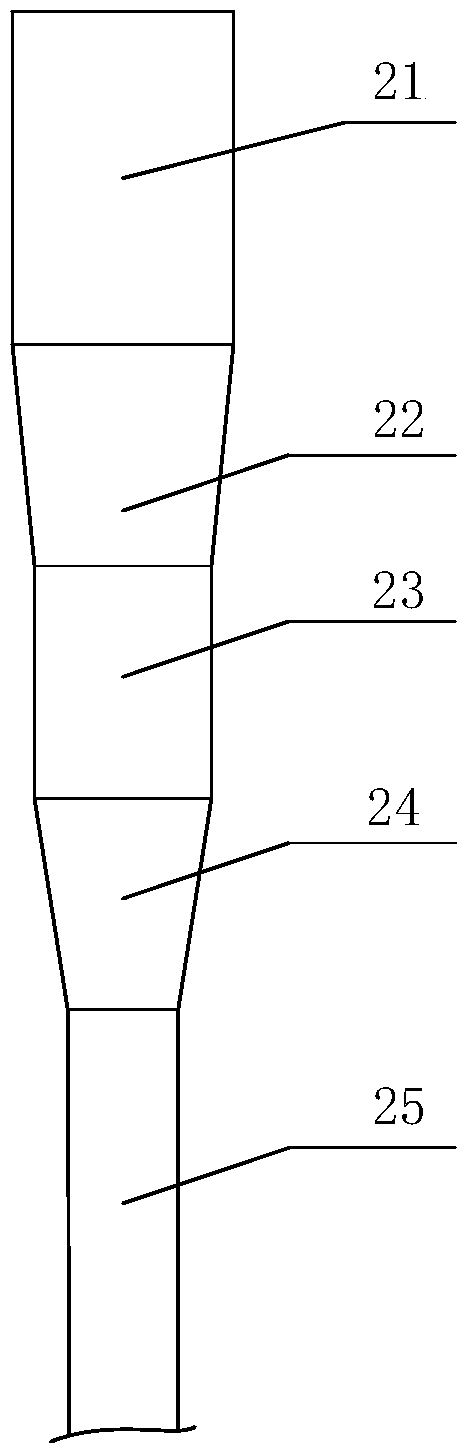

[0042] figure 2Another seeding process involved in the Czochralski silicon single crystal seeding method is given. This seeding process can be divided into initial seeding 21 , first diameter reduction process 22 , etc. fine grain process 23 , second diameter reduction process 24 , and seeding 25 after the second diameter reduction process. In the etc. fine crystal process 23, using the Czochralski single crystal silicon seeding method of the present invention, at least the seeding speed deviation is used as a parameter for regulating and controlling the seeding temperature, and the seeding speed deviation is within the temperature regulation period of the seeding The difference between the average seeding speed and the set seeding speed.

[0043] After the single crystal is introduced, the seeding diameter of the seeding initial stage 21 is usually 12-16mm. In order to eliminate dislocations in the extracted single crystal, a first diameter reduction process 22 needs to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com