Distillation process and system adopting solid alkali for coking wastewater

A coking wastewater and distillation system technology, which is applied in the field of coking wastewater distillation process and system, can solve the problems of increasing the consumption of steam and cooling water at the bottom of the tower, and the discharge of ammonia distillation wastewater, so as to reduce the amount of wastewater discharged at the bottom of the tower, reduce the The effect of consumption, saving equipment investment and land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

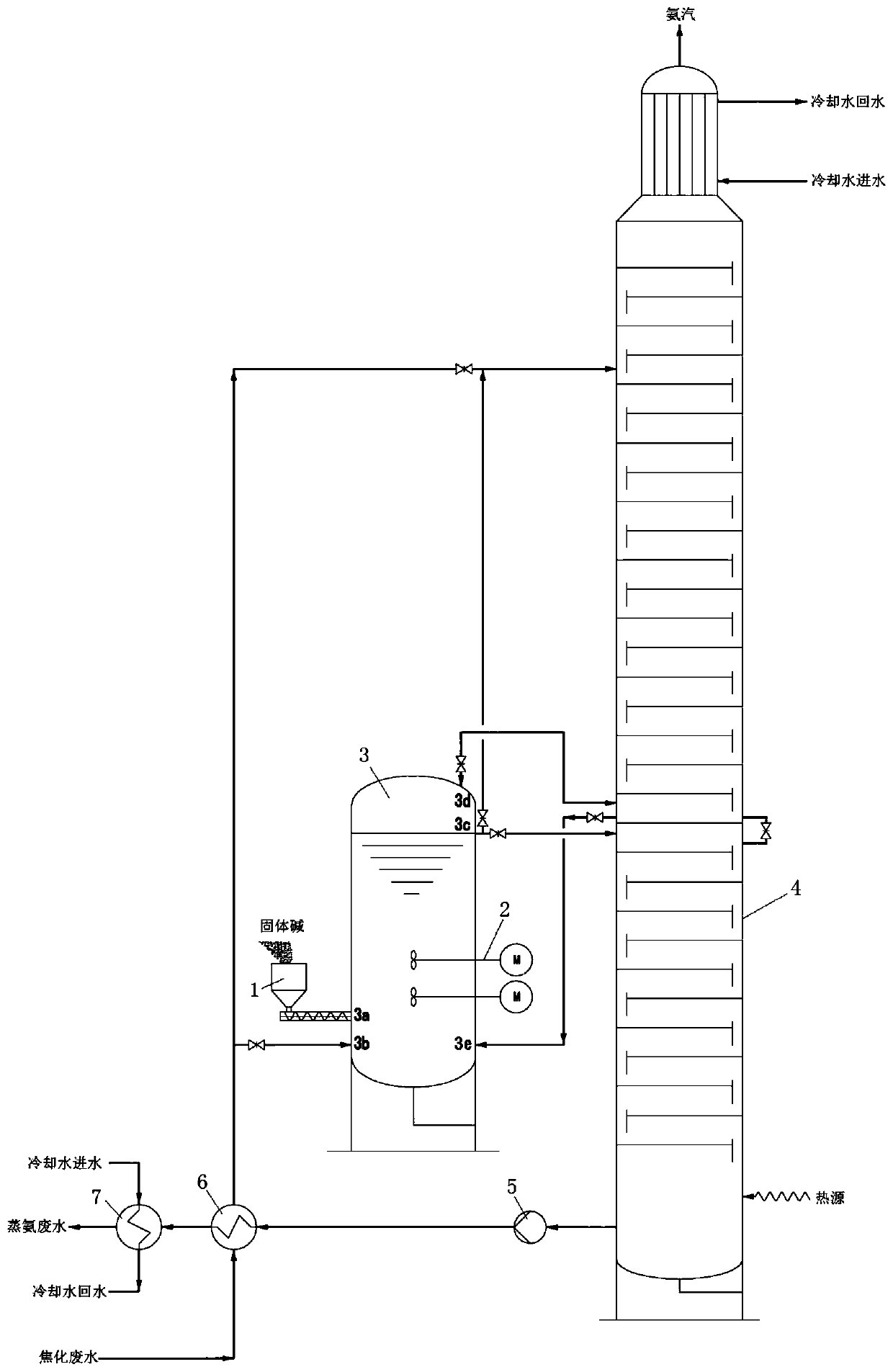

[0030] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0031] Such as figure 1 Shown, a kind of coking waste water distillation process that adopts solid alkali of the present invention comprises the steps:

[0032] 1) The raw waste water from each unit of the gas purification system enters the raw waste water-ammonia distillation waste water heat exchanger 6, and after exchanging heat with the ammonia distillation waste water from the bottom of the distillation tower 4, one way directly enters the upper part of the distillation tower 4, and the other way enters the bottom of the mixing tank 3;

[0033] 2) Input the solid alkali into the mixing tank 3 through the solid feeding device 1, the solid alkali is mixed with the raw waste water to form an alkaline solution and then directly enters the upper part of the distillation tower 4, or the solid alkali is mixed with the liquid phase extracted from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com