Double-mold-cavity laminated injection mold of round air outlet grid

A technology for injection molds and air outlet grills, which is applied in the field of double-cavity laminated injection molds, can solve problems such as low production efficiency and inability to meet demand, and achieve the effects of reducing costs, improving equipment utilization and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

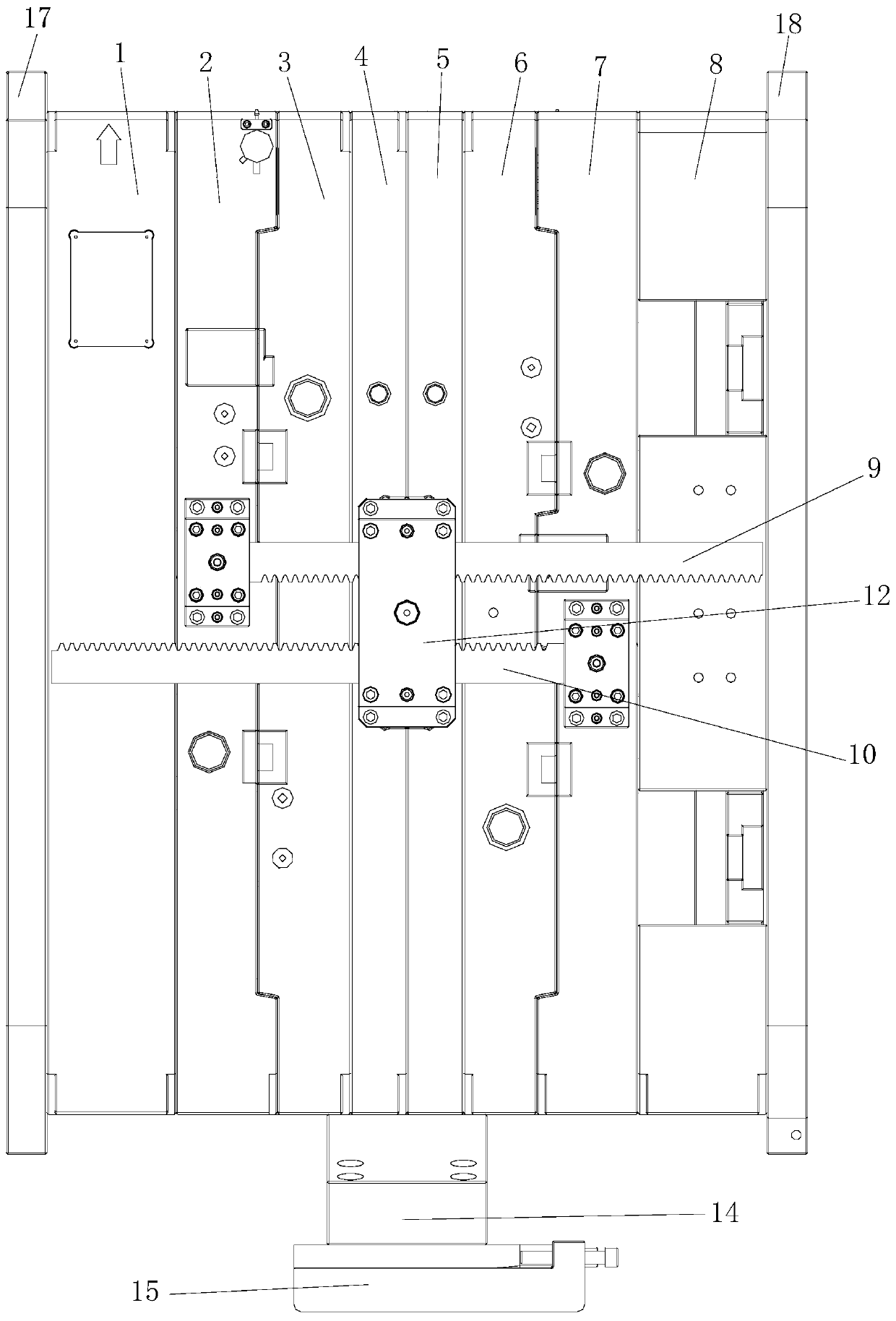

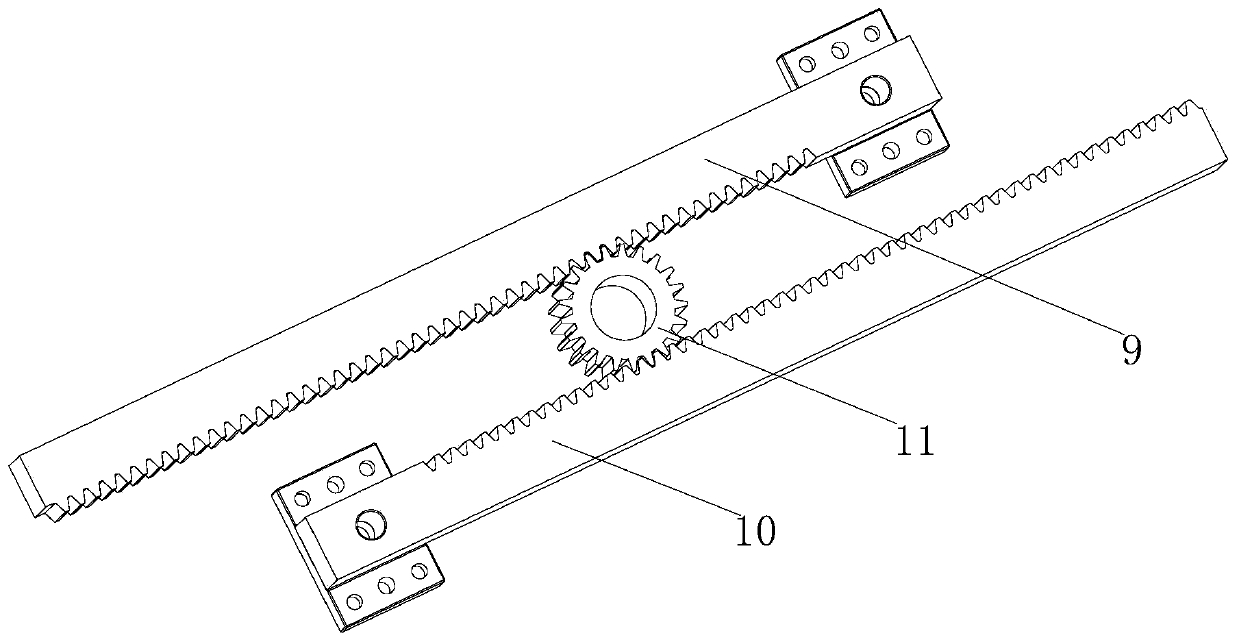

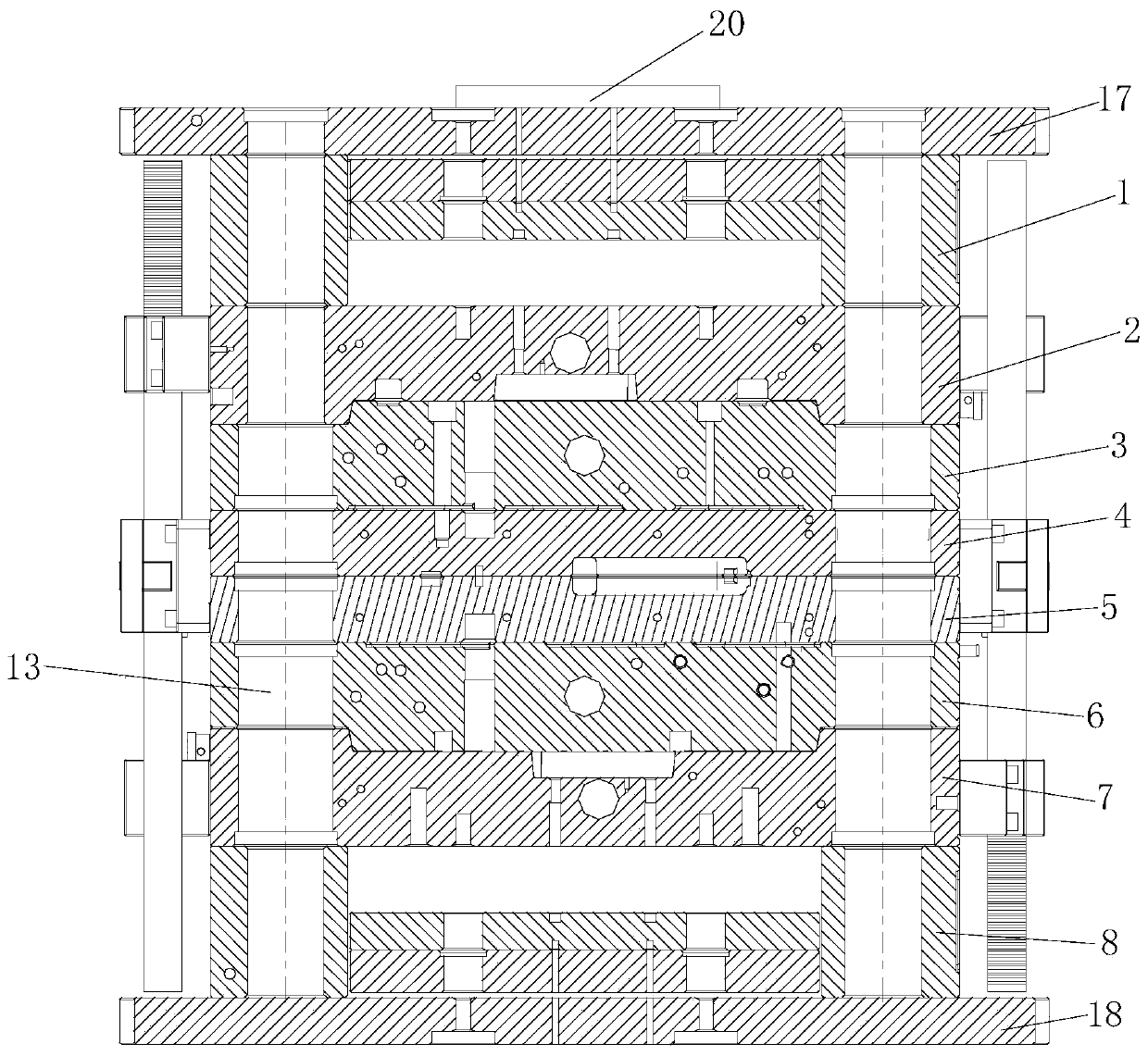

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. Such as Figure 1-9 As shown, the double-cavity laminated injection mold with circular air grille includes first seat plate 17, first mold foot 1, first movable mold 2, first fixed mold 3, first hot runner plate 4, second The second hot runner plate 5, the second fixed mold 6, the second movable mold 7, the second mold foot 8, and the second seat plate 18, the first movable mold 2 and the first fixed mold 3 cooperate to form two mold cavities, The second fixed mold 6 and the second movable mold 7 cooperate to form two mold cavities, that is, there are four mold cavities in total. Guide post holes are also formed in the mold, and travel guide posts 13 are arranged in the guide post holes. One end of the travel guide post 13 is fixed on the first seat plate 17, and the other end is located at the second die foot. 8, the first fixed mold 3, the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com