Gel tube preparation device and micron-sized gel tube prepared by same and used for glaucoma drainage

A preparation device and micron-scale technology, applied in ophthalmic surgery, coating, etc., can solve the problems of complex preparation process, easy to cause infection, uneven thickness, etc., achieve simple preparation process, easy process control, suitable for large-scale industrialization The effect of rapid production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0075] According to one aspect of the present invention, a kind of preparation method of above-mentioned gel tube, described method comprises the following steps:

[0076] The wire 2 enters the gel cavity 1 through the wire inlet 11 through the wire drawing device 3, and adheres the gel solution in the gel inner cavity 13, and then passes through the center of the wire outlet 12, so that the surface of the wire 2 The gel solution is adhered, and then the metal wire 2 with the gel solution adhered on the surface is solidified, and finally the metal wire 2 is drawn out to obtain a gel tube.

[0077] The preparation method of the gel tube provided by the present invention is that the metal wire 2 enters the gel chamber 1 through the wire drawing device 3 through the wire inlet 11, and adheres the polymer hydrogel material in the gel inner chamber 13 The gel solution passes through the center of the wire outlet 12 subsequently, so that the surface of the metal wire 2 is adhered to...

Embodiment 1

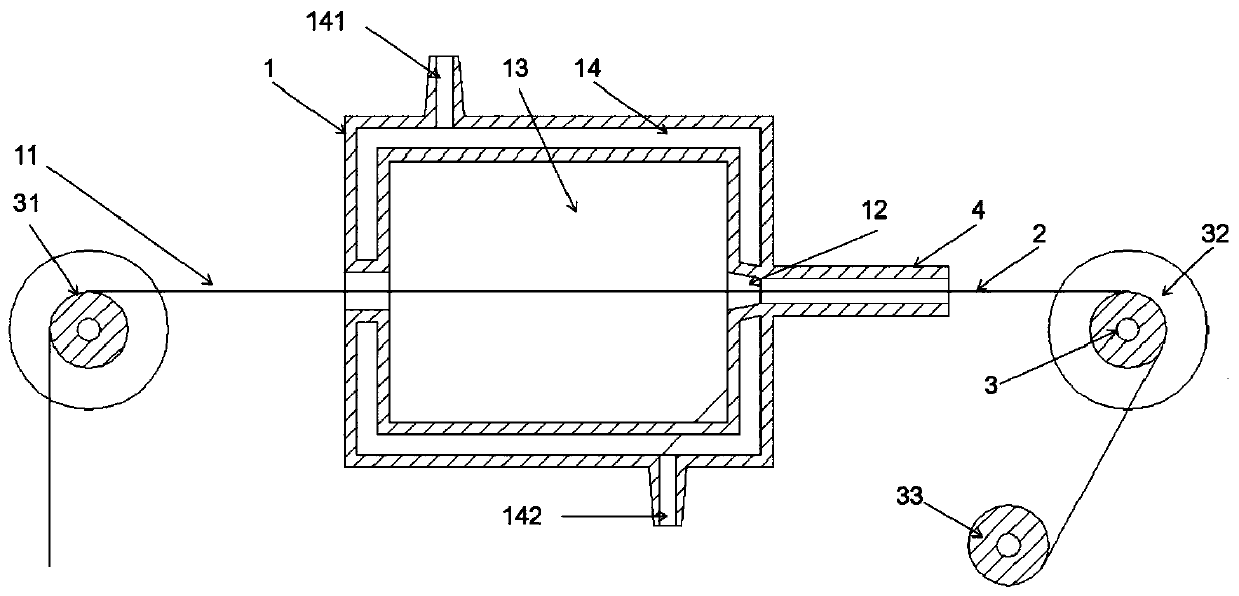

[0099] Such as figure 1 As shown, a gel tube preparation device, the preparation device includes a gel cavity 1, a wire 2 and a wire drawing device 3;

[0100] The gel cavity 1 is mainly composed of a gel inner cavity 13 and a thermal insulation outer cavity 14 that are coated inside and outside;

[0101] The gel chamber 1 is provided with a wire inlet 11 and a wire outlet 12, the wire 2 enters the gel chamber 1 from the wire inlet 11 through the wire drawing device 3, and adheres in the gel inner chamber 13 After the gel is passed through the center of the wire outlet 12, the outer layer of the wire 2 coated with gel is obtained, and the wire 2 is drawn out after curing and forming to prepare a gel tube;

[0102] The ratio of the inner diameter of the wire outlet 12 to the diameter of the wire 2 is 4˜2:1.

[0103] The gel tube preparation device provided in this embodiment includes a gel cavity 1, a metal wire 2 and a wire drawing device 3; the gel cavity 1 is mainly compos...

Embodiment 2

[0113] A micron gel tube for glaucoma drainage, the gel tube is made by the gel tube preparation device of the above-mentioned embodiment 1;

[0114] Wherein, the inner diameter of the metal wire outlet 12 in the preparation device is 400 μm, and the diameter of the metal wire 2 is 100 μm.

[0115] The specific preparation steps of the above-mentioned micron gel tube for glaucoma drainage are as follows:

[0116] (1) Dissolve 20g of gelatin solution in 40ml of water and heat to 50°C to dissolve overnight. Add the dissolved gelatin solution into the gel chamber 1 after ultrasonic defoaming;

[0117] (2), before the preparation starts, hot water enters from the insulation solution inlet 141, and the temperature of the gelatin solution is kept at about 50°C through the insulation outer cavity 14, so as not to solidify during the preparation of the gel tube. Liquid outlet 142 flows out to complete the whole hot water cycle;

[0118] (3), in the forming stage of the gel tube, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com