Dust removal system for sheet metal processing

A technology for dust removal systems and sheet metal parts, applied in metal processing equipment, smoke removal, manufacturing tools, etc., can solve the problems of harmful workers' health, easy adsorption, etc., to reduce the possibility, reduce the possibility of damage to workers' health, protect Worker health effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] refer to figure 1 , a dust removal system for sheet metal processing, which includes a frame 1 arranged along the height direction of the workshop.

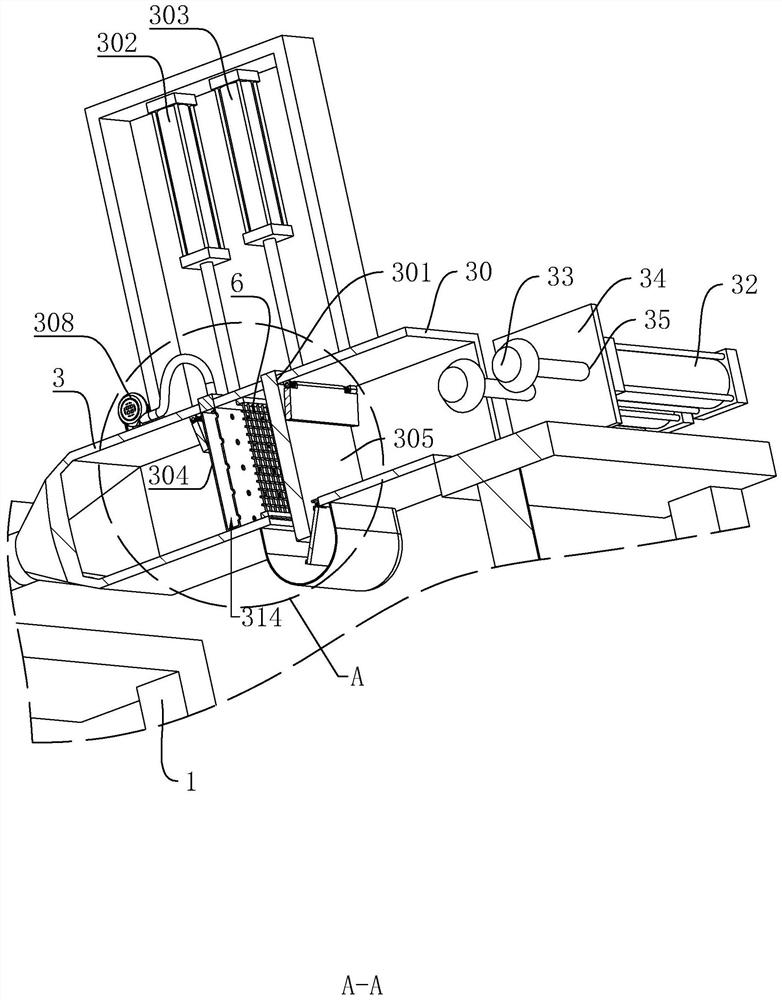

[0044] refer to figure 2 , There is an exhaust fan 2 on the frame 1, the exhaust fan 2 adopts an adjustable speed fan, the air inlet pipe 3 is arranged on the air inlet side wall of the exhaust fan 2, and the air outlet pipe is arranged on the air outlet side wall of the exhaust fan 2 20, the end of the air outlet pipe 20 away from the exhaust fan 2 is provided with a filter box 21, preferably an activated carbon filter is used in the filter box 21, and the end of the air inlet pipe 3 close to the exhaust fan 2 is provided with a filter screen 6 (refer to image 3 ), the end of the air inlet pipe 3 away from the exhaust fan 2 is provided with a sealing plate 7, and the side wall of the sealing plate 7 is connected with an air conveying pipe 4 and a conveying pipe 5, and the air conveying pipe 4 and the conveying pipe 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com