Steel ladle double-ventilation core

A technology of air-permeable core and ladle, which is applied in the direction of casting melt container, metal processing equipment, casting equipment, etc. It can solve the problems of excessive carbon content and carbon increase in stainless steel, achieve the optimization of ladle flow field, improve the service life, and realize the temperature of molten steel Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The method of the present invention will be further described below in conjunction with the examples, but the present invention is not limited thereto.

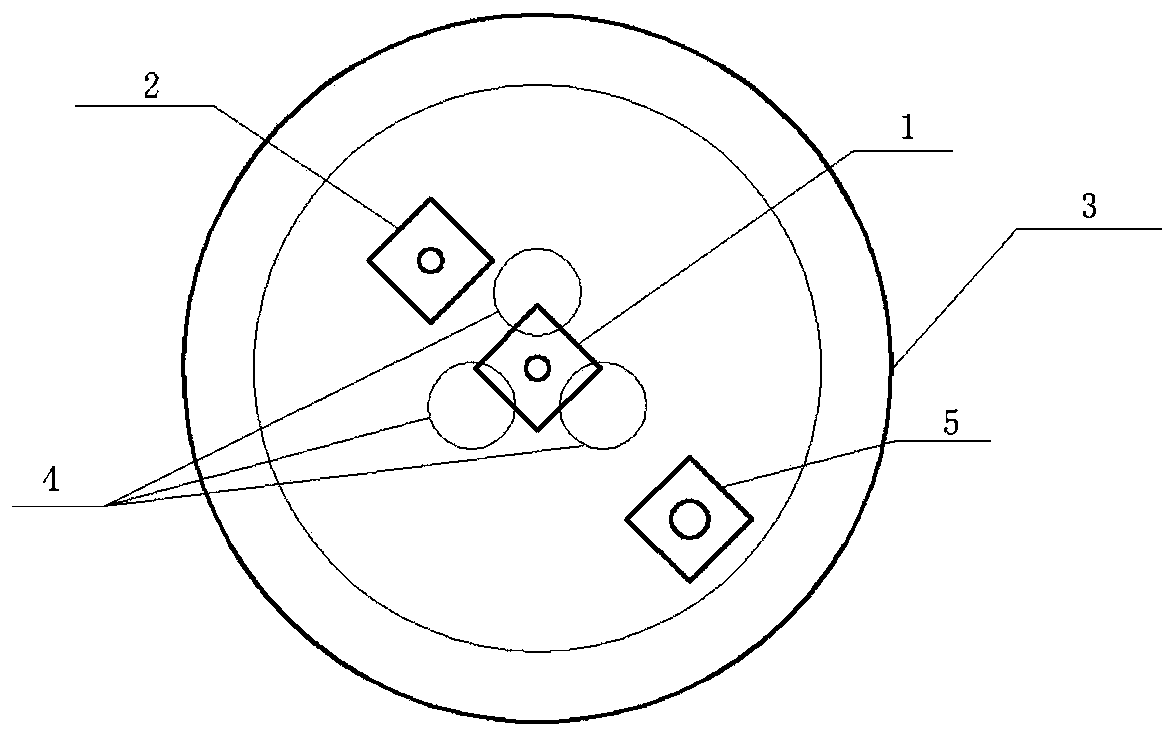

[0013] A double air-permeable core for a ladle, comprising an air-permeable core, a steel ladle 3, an electrode 4, and a nozzle 5, and the center of the cross-section of the electrode 4 is evenly distributed on a circle centered on the center of the cross-section of the ladle 3; the air-permeable core includes A Breathable core 1, B breathable core 2, the center line of the A breathable core 1 is the same as the center line of the steel ladle 3, and the B breathable core 2 is set at 1 / 2 of the distance from the center line of the steel ladle 3 to the inner wall of the steel ladle 3.

[0014] The cross-sectional center of the A breathable core 1, the cross-sectional center of the B breathable core 2 and the cross-sectional center of the nozzle 5 are arranged on the same symmetrical plane of the ladle 3, and the B breatha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com