Electromagnetic shielding conductive foam and preparation method thereof

A conductive foam and electromagnetic shielding technology, which is applied in the fields of magnetic/electric field shielding, electrical components, screening casings, etc., can solve the problems of insufficient adhesive viscosity, affecting shielding effectiveness, and easy loosening, etc., to increase efficiency, Counteracts stress and prevents detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

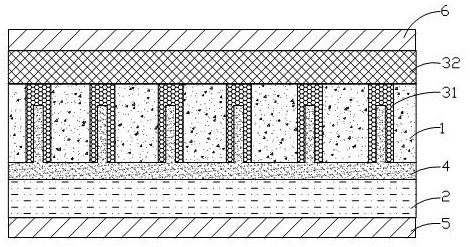

[0030] see Figure 1-2 As shown, the embodiment of the present invention discloses an electromagnetic shielding conductive foam, including a conductive foam layer 1, a metal foil layer 2 disposed below the conductive foam layer 1, and a rubber column assembly 3. The conductive foam layer 1 is evenly A plurality of positioning holes are arranged on the ground, and the rubber column assembly 3 includes a plurality of rubber columns 31 and a rubber connecting plate 32 connecting one end of the plurality of rubber columns 31. The plurality of rubber columns 31 correspond to the plurality of positioning holes one by one, and the rubber columns 31 Set in the positioning hole, the rubber connecting plate 32 is bonded to the upper end surface of the conductive foam layer 1 by glue, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com