Waterproof structure of pitched roof eave gutter and construction method of waterproof structure

A technology of waterproof structure and sloping roof, applied in the direction of roof, roof covering, building structure, etc., can solve the problems of heavy waterproof membrane, increased cost, increased load, etc., to avoid self-heavy load, prolong service life, The effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

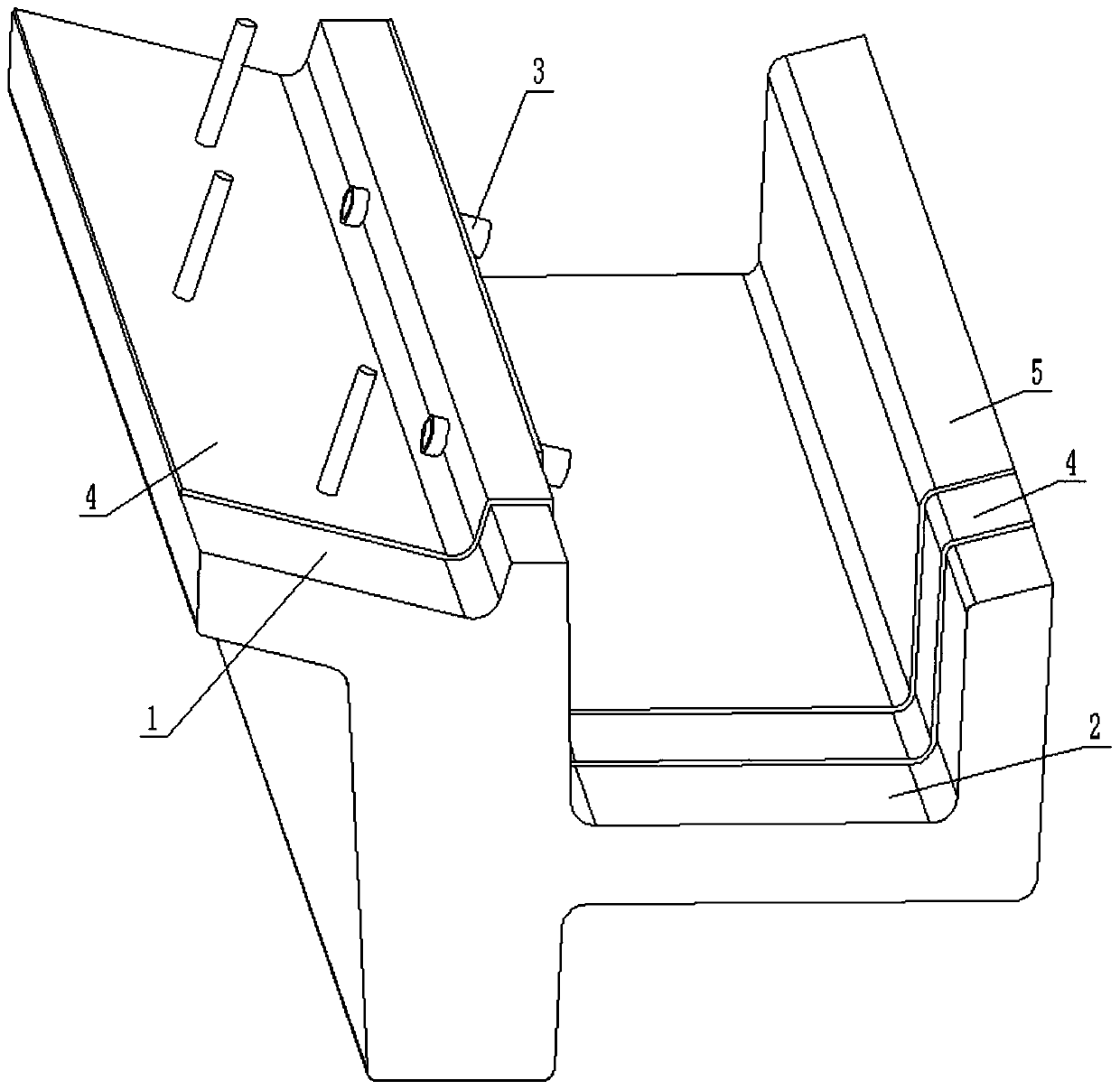

Image

Examples

Embodiment Construction

[0021] First, the design idea of the present invention is explained: most of the modern buildings are concrete buildings, and in the process of building construction, the main body is supported by a steel skeleton, and after the main body of the building is completed, the gutter will be built at the position of the eaves, using It collects rainwater in rainy days and diverts it to the pipes on both sides. However, since the main body of the gutter is made of concrete, if no measures are taken, cracks will appear on the surface under long-term environmental erosion. Or potholes, these cracks or potholes will accumulate water in rainy weather, and then further expand the cracks. If things go on like this, the gutters will not be able to play the role of water collection and diversion. On the contrary, the gutters themselves will seep, which will affect the building The wall will cause harm. In order to avoid this situation, waterproof materials will be added to the surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com