A kind of rh brick with excellent mud retention and preparation method thereof

A kind of mud material and excellent technology, which is applied in the field of periclase-spinel bricks for RH furnaces, can solve the problems of easy drying of mud material and large deviation of first and last single weight, and achieve slow water volatilization speed, good moisturizing performance, The effect of improving brick forming quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A kind of RH brick with excellent moisture retention of mud material, mixed and milled according to 600kg, the composition is as follows: 97 fused magnesia particles 5-3mm are 15%, 3-1mm is 15%, 1-0mm is 15%, 97 fused magnesia Fine powder 240 mesh (61μm) is 30%, fused magnesia aluminum spinel particles 1-0mm is 14%, fused magnesia aluminum spinel fine powder 325 mesh (45μm) is 5%, magnesium aluminum gel binder 3%, commercially available antioxidant aluminum-silicon alloy powder 1%, humectant (citric acid and glucose mixed at 0.8:1) 2%, tap water 1.2%.

[0020] In this embodiment, after the humectant is introduced, the effective molding time of the mud is extended from 30 minutes to 50 minutes. It takes 40-50 minutes for each mud press to form, and the press forms a brick with a theoretical unit weight of 14.7kg, of which the unit weight of the first brick is 14.7kg, and the unit weight of the last brick is 14.65kg, with a small drop in the first and last unit weight.

...

Embodiment 2

[0025] A kind of RH brick with excellent moisture retention of mud material, mixed and milled according to 600kg, the composition is as follows: 97 fused magnesia particles 5-3mm are 20%, 3-1mm is 20%, 1-0mm is 25%, 97 fused magnesia Fine powder 240 mesh is 10%, fused magnesia aluminum spinel particles 1-0mm is 10%, fused magnesia aluminum spinel fine powder 325 mesh is 6%, magnesium aluminum gel binder 4%, commercially available anti Oxidant aluminum-silicon alloy powder 2%, humectant (citric acid and glucose mixed at 0.8:1) 3%, tap water 1.3%.

[0026] In this embodiment, after the humectant is introduced, the effective molding time of the mud is extended from 30 minutes to 50 minutes. It takes 40-50 minutes for each mud press to form a brick, and the press forms a brick with a theoretical unit weight of 14.7kg, of which the unit weight of the first brick is 14.7kg, and the unit weight of the last brick is 14.68kg, with a small drop in the first and last unit weight.

[002...

Embodiment 3

[0031] A kind of RH brick with excellent moisture retention of mud material, mixed and milled according to 600kg, the composition is as follows: 97 fused magnesia particles 5-3mm are 20%, 3-1mm is 15%, 1-0mm is 20%, 97 fused magnesia Fine powder 240 mesh is 10%, fused magnesia aluminum spinel particles 1-0mm is 15%, fused magnesia aluminum spinel fine powder 325 mesh is 10%, magnesium aluminum gel binder 4%, commercially available anti Oxidant aluminum-silicon alloy powder 3%, humectant (citric acid and glucose mixed at 0.8:1) 3%, tap water 1.3%.

[0032] In this embodiment, after the humectant is introduced, the effective molding time of the mud is extended from 30 minutes to 50 minutes. It takes 40-50 minutes for each mud press to form, and the press forms a brick with a theoretical unit weight of 14.7kg, of which the unit weight of the first brick is 14.7kg, and the unit weight of the last brick is 14.66kg, with a small drop in the first and last unit weight.

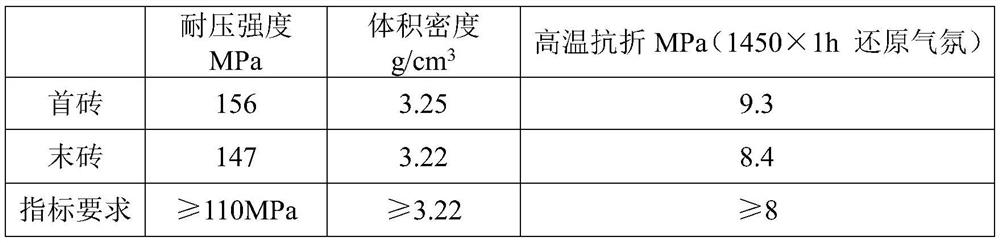

[0033] RH b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com