A kind of wheel hub extrusion forming method

A technology of extrusion forming and wheel hubs, which is applied in the directions of wheels, transportation and packaging, and metal processing equipment, etc., can solve the problems that the excellent mechanical properties cannot be fully exerted, the performance of the hubs cannot reach the best, and the quality of the hub forming is not good. The forming process is simple and easy, the material utilization rate is improved, and the grain is compacted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] A hub extrusion forming method. Taking a magnesium alloy wheel hub whose material is AZ80 as an example, the process of manufacturing the wheel hub by adopting the wheel hub extrusion forming method of the present invention is divided into two parts: the pre-forging forming of the rim and the inner rim and the final forging forming of the spoke and the outer rim .

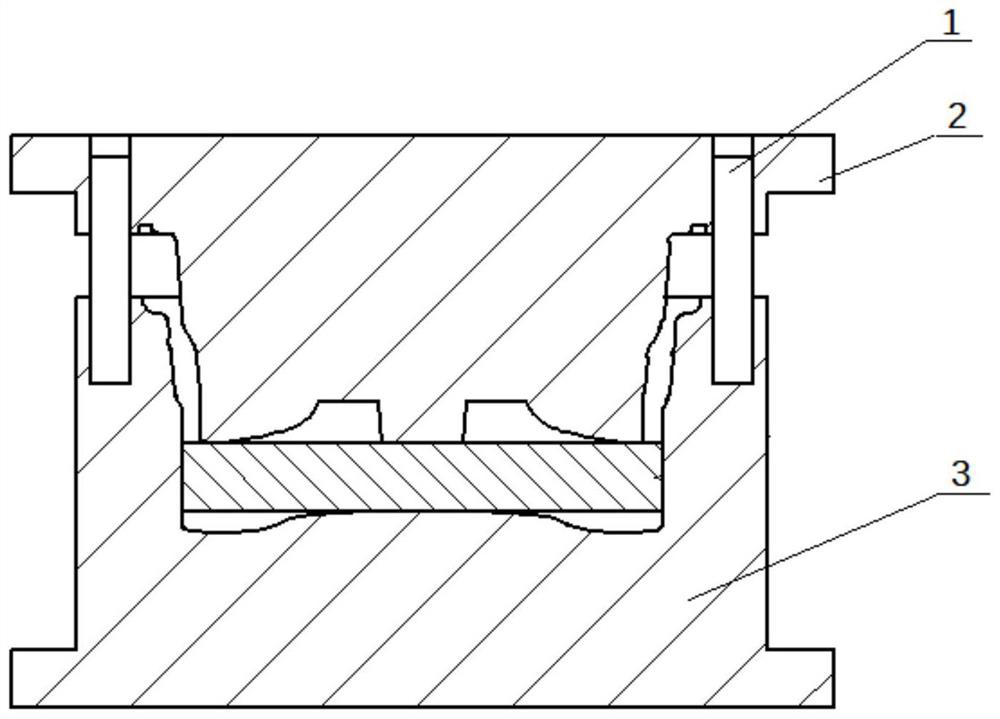

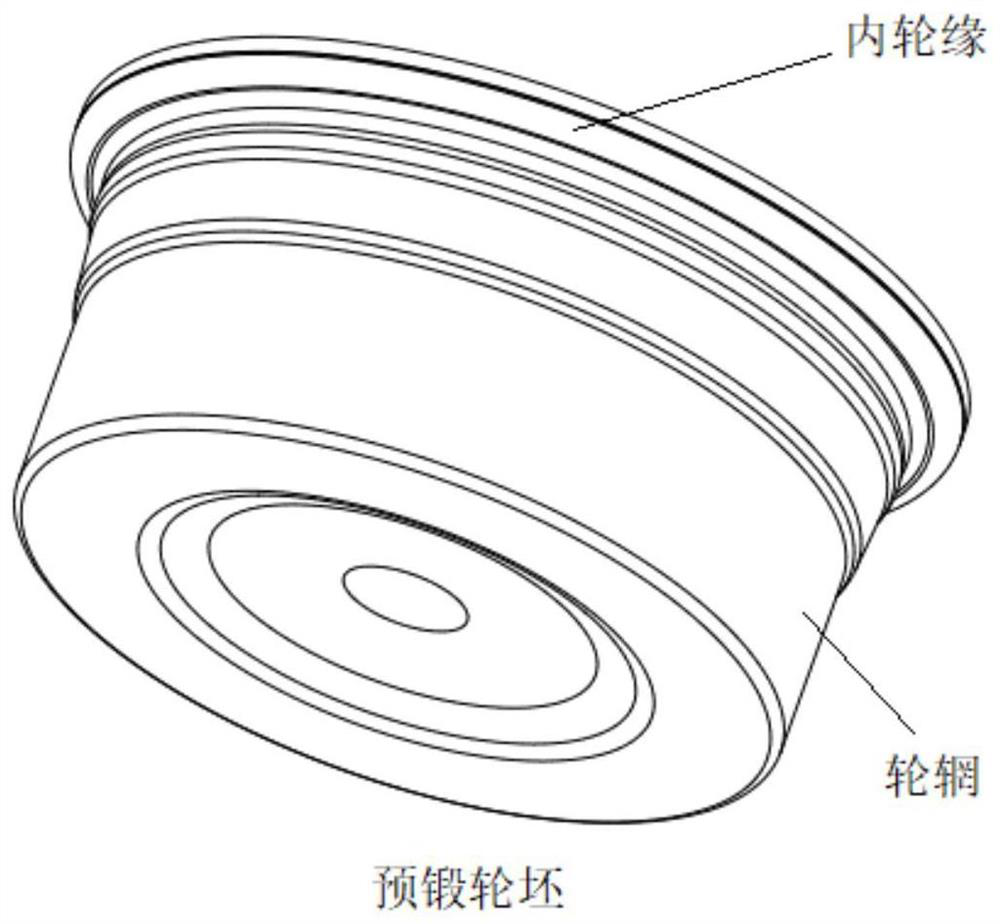

[0030] Pre-forging forming process: 1. Obtain a cylindrical cake-shaped magnesium alloy billet, put the billet into a heating furnace to heat at 300-450°C, and keep it warm for a period of time; 2. Put the preheated billet flat into the pre-forging mold cavity place them together on the working table of the hydraulic press, push the pre-forging upper punch 2 to extrude downward, and back-extrude to obtain the complete pre-forged wheel blank with the rim and inner rim of the wheel hub, and obtain the pre-forged wheel blank after simple processing Such as Figure 7 shown;

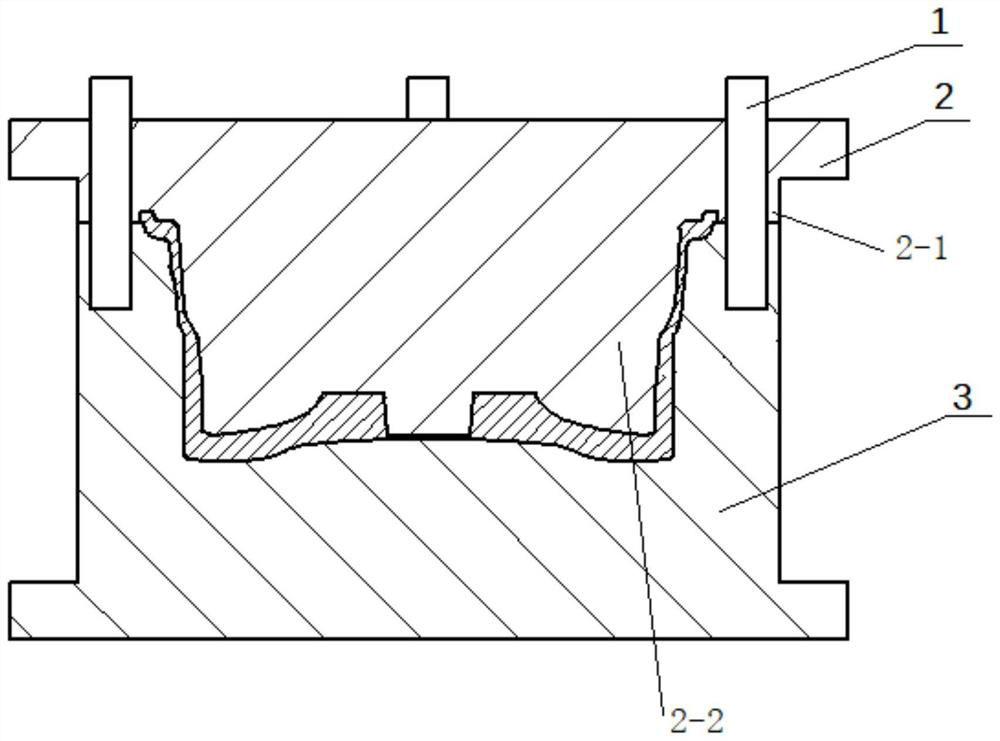

[0031] Final forging forming proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com