A near-net-shape method for thin-plate titanium alloy forgings with warping

A near-net shape, titanium alloy technology, applied in the field of forging and forming of structural parts, can solve problems affecting the mechanical properties of materials, achieve the effect of improving surface quality and reducing defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

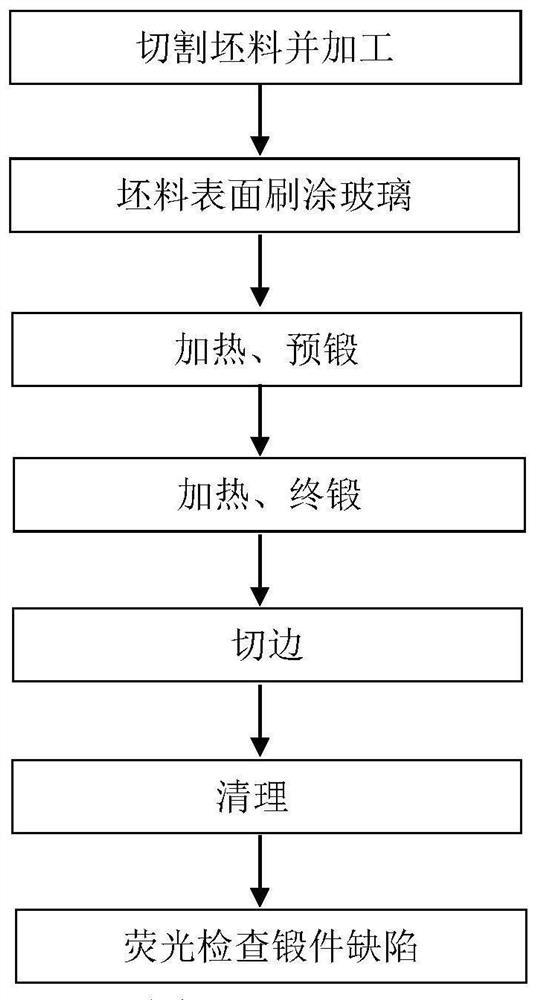

[0039] Below in conjunction with accompanying drawing, the present invention will be described in further detail; figure 1 The flow chart of the present invention, the specific process of forging with warped thin plate titanium alloy precision forging is:

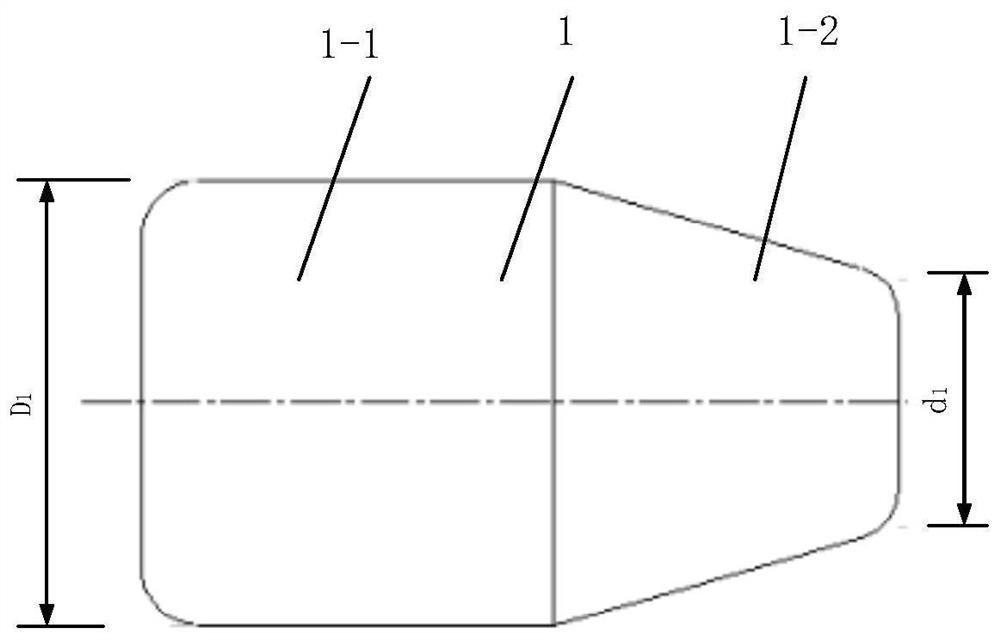

[0040] 1. Cut the blank and process it

[0041] According to the calculated blank size, the lathe is used to cut the blank, and according to the size requirements of the target final forging, one end of the blank is turned and inverted to form the original blank 1, and the original blank 1 includes a cylinder 1-1 and an inverted cone 1- 2, such as figure 2 As shown, the diameter of cylinder 1-1 is D 1 , the diameter of the inverted frustum 1-2 is d 1 , machining surface roughness Ra=1.6μm; cylinder 1-1 and inverted truncated cone 1-2 are two parts of original blank 1, and are integrally connected. One end of the body 1-1 is connected, and the small end face of the inverted cone 1-2 is the outer end face; the edge of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com