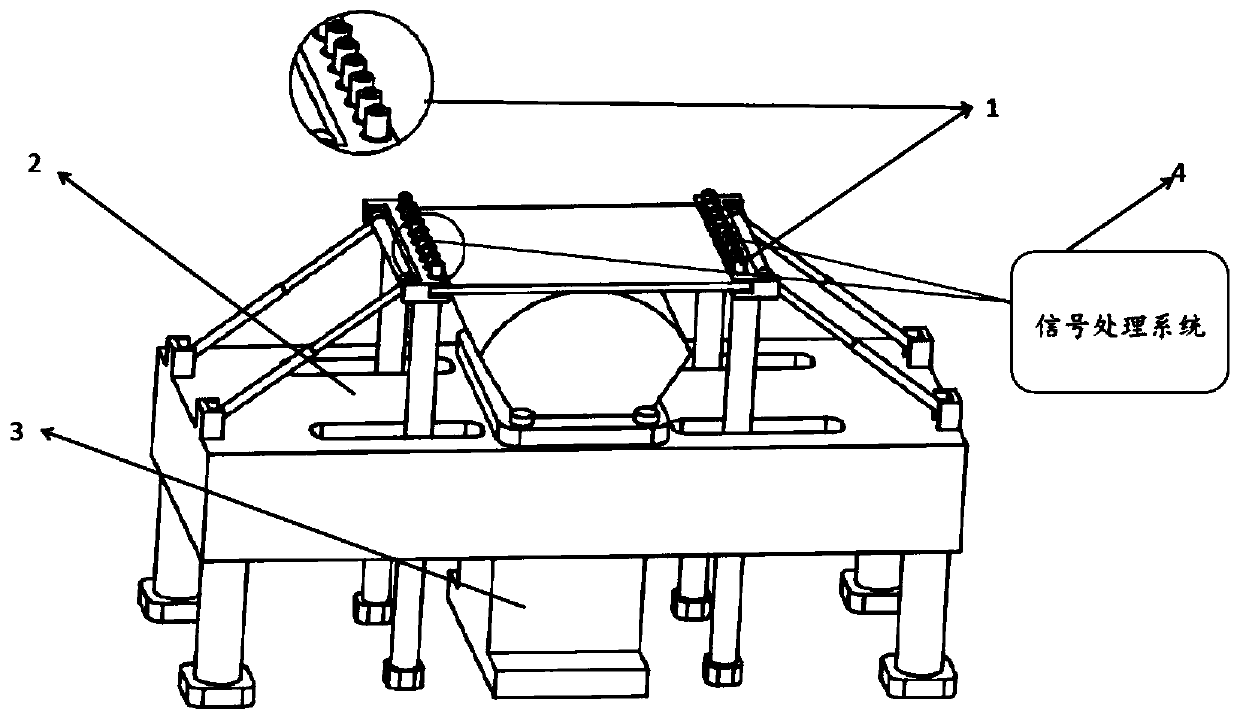

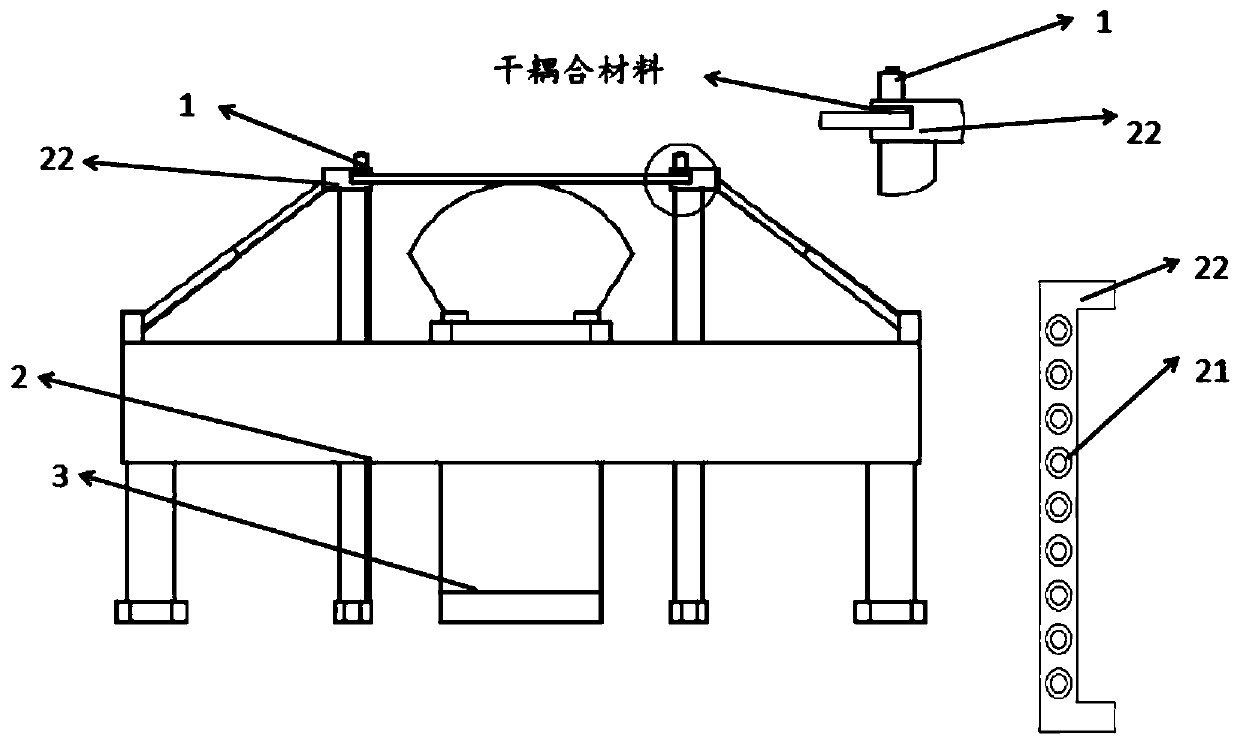

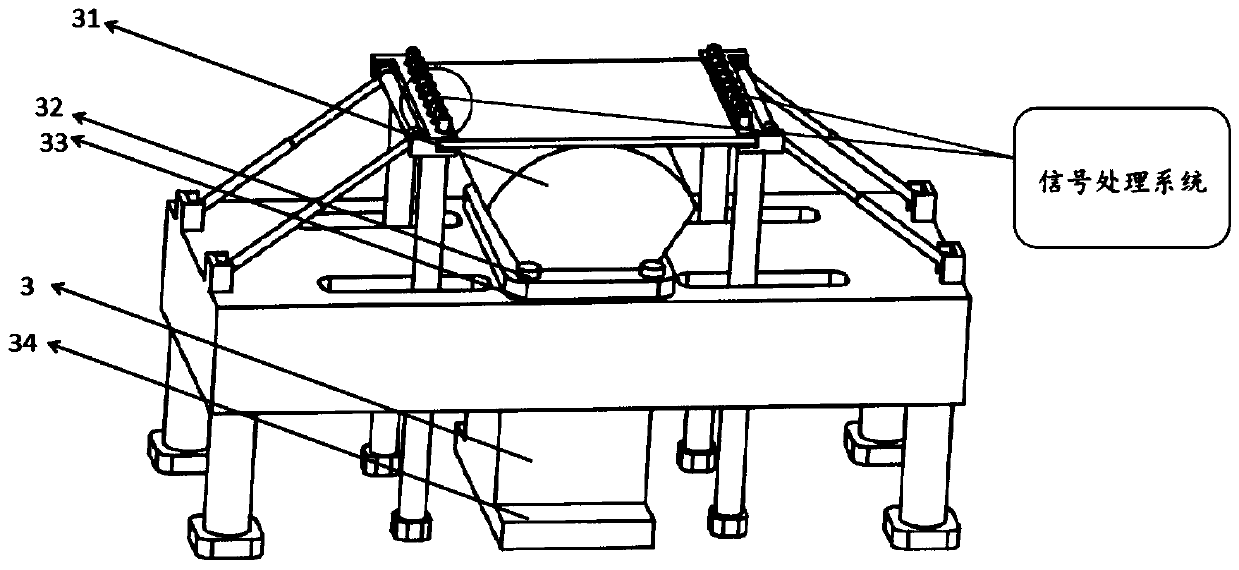

Skin stretching defect online detection device

A detection device and skinning technology, applied in transportation and packaging, manufacturing tools, aircraft parts, etc., can solve problems such as insufficient forming, uneven thickness of skin parts, material waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to make the above objects, features and advantages of the present application more obvious and comprehensible, the present application will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

[0052] In related technologies, the stretching test of the aircraft skin is performed after the aircraft skin is processed. The inspector uses a detection device to scan the aircraft skin. If a defect is detected in the aircraft skin, the aircraft skin is discarded. However, the completion of aircraft skin processing requires multiple processes such as plate rolling→annealing→cleaning→solution treatment→stretch forming→aging→machining→surface treatment. After the aircraft skin processing is completed, the skin tensile test will Cause useless processing of aircraft skin, also can cause the waste of aircraft skin material.

[0053]The aircraft skin is an alloy material. During the stretching process, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com