Termination structure of split gate vdmos devices

A terminal structure and separation gate technology, which is applied in semiconductor devices, electrical solid state devices, electrical components, etc., can solve the problems of affecting device withstand voltage, increasing design difficulty, and complex charge balance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

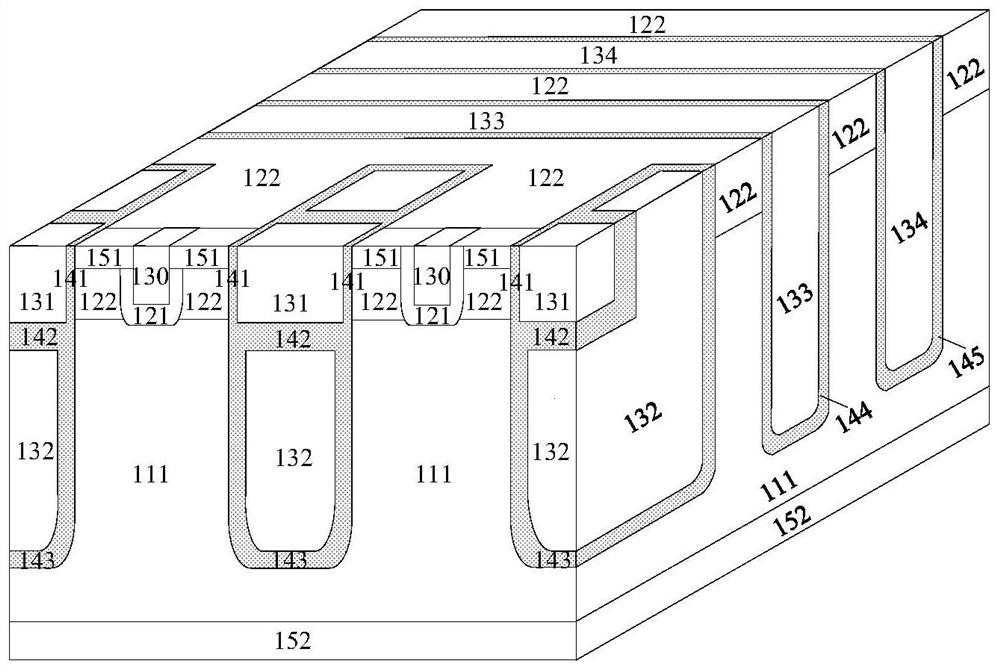

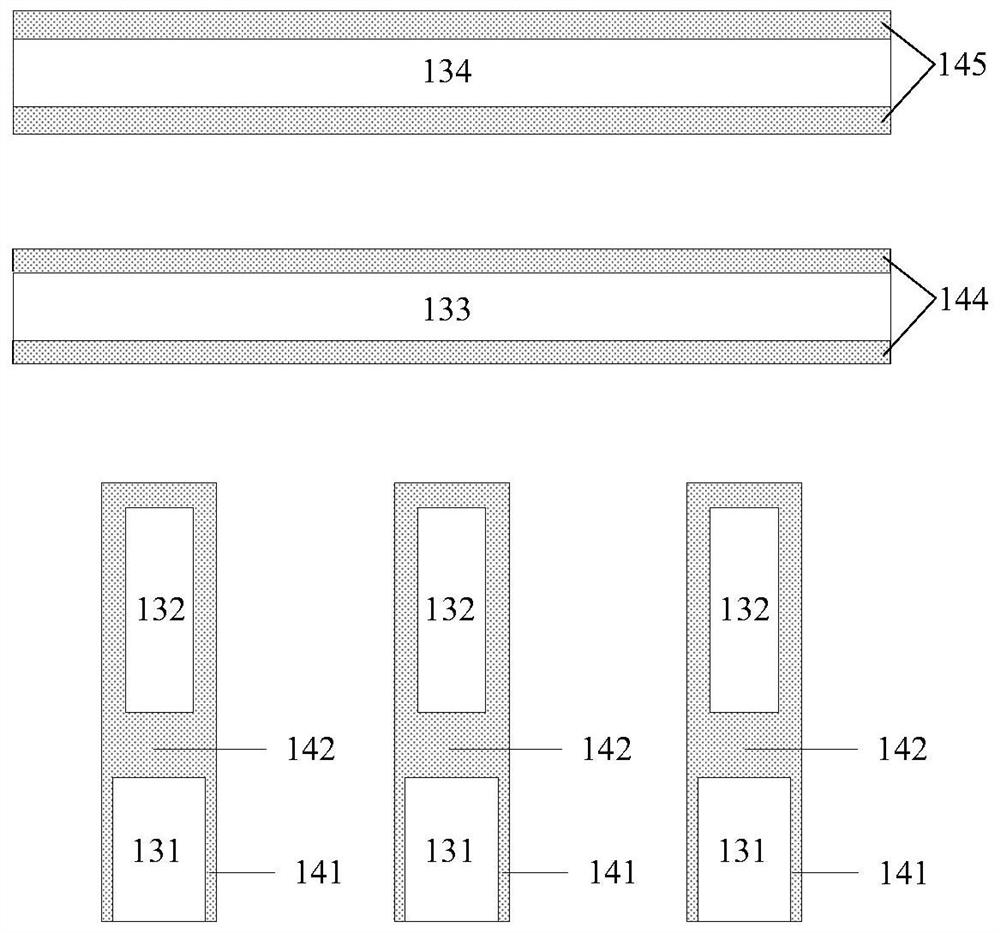

[0026] Such as image 3 and Figure 4 As shown, it is a schematic structural diagram of the split-gate VDMOS device in Example 1 of the present invention, including the structure of the active region and the structure of the terminal region:

[0027] The active region structure includes: a first conductivity type substrate 152, a first conductivity type drift region 111, a first conductivity type source contact region 151, a second conductivity type well region 122, and a second conductivity type source contact region 121, the source metal contact 130, the first dielectric oxide layer 141, the second dielectric oxide layer 142, the third dielectric oxide layer 143, the control gate polysilicon electrode 131, and the separation gate polysilicon electrode 132; the drift region 111 of the first conductivity type is located in the second Above the substrate 152 of a conductivity type, the well region 122 of the second conductivity type is located above the drift region 111 of the...

Embodiment 2

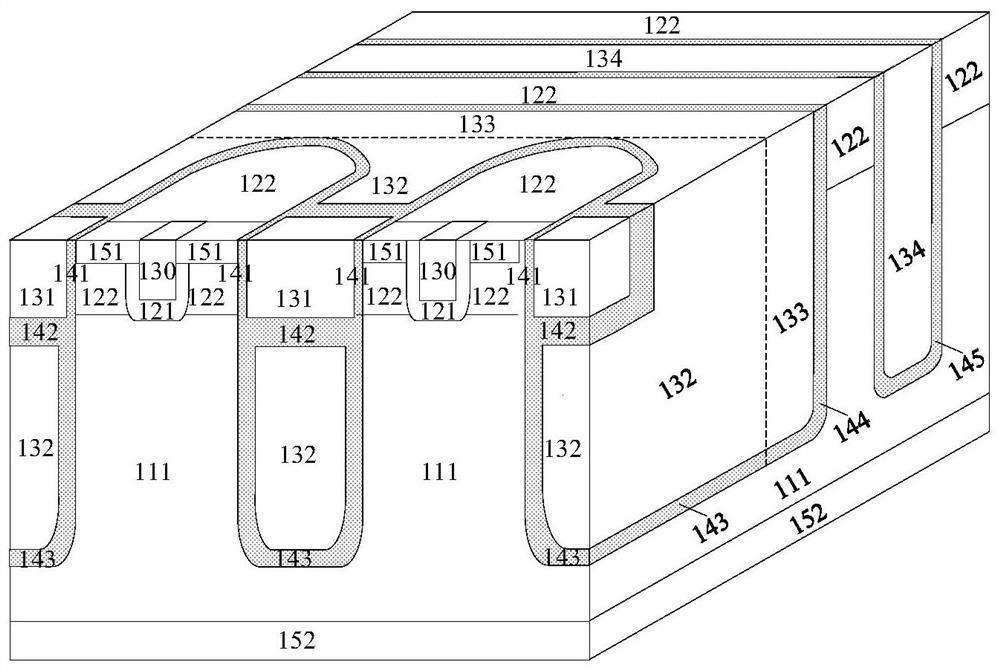

[0035] Such as Figure 5As shown, it is a schematic diagram of the terminal structure of the split-gate VDMOS device in Embodiment 2 of the present invention. The difference between this example and Embodiment 1 is that the arc diameter at the junction of the split-gate deep groove and the first terminal deep groove is larger than the separation pitch of deep trenches. The purpose is to further alleviate the curvature effect and optimize the charge balance, the principle of which is basically the same as that of Embodiment 1.

Embodiment 3

[0037] Such as Figure 6 As shown, it is a schematic diagram of the terminal structure of the split-gate VDMOS device in Embodiment 3 of the present invention. The difference between this example and Embodiment 1 is that the connection between the split-gate deep groove and the first terminal deep groove is at a right angle, and the connection is not opposite. The structure is chamfered to reduce the difficulty of design and manufacture, and the principle is basically the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com