Hexahedral cylinder type fractional groove concentrated winding type active vibration absorber

A technology of concentrated winding and vibration absorber, applied in springs/shock absorbers, springs, magnetic springs, etc., can solve problems such as poor adaptability, and achieve the effect of good dynamic characteristics and rapid response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

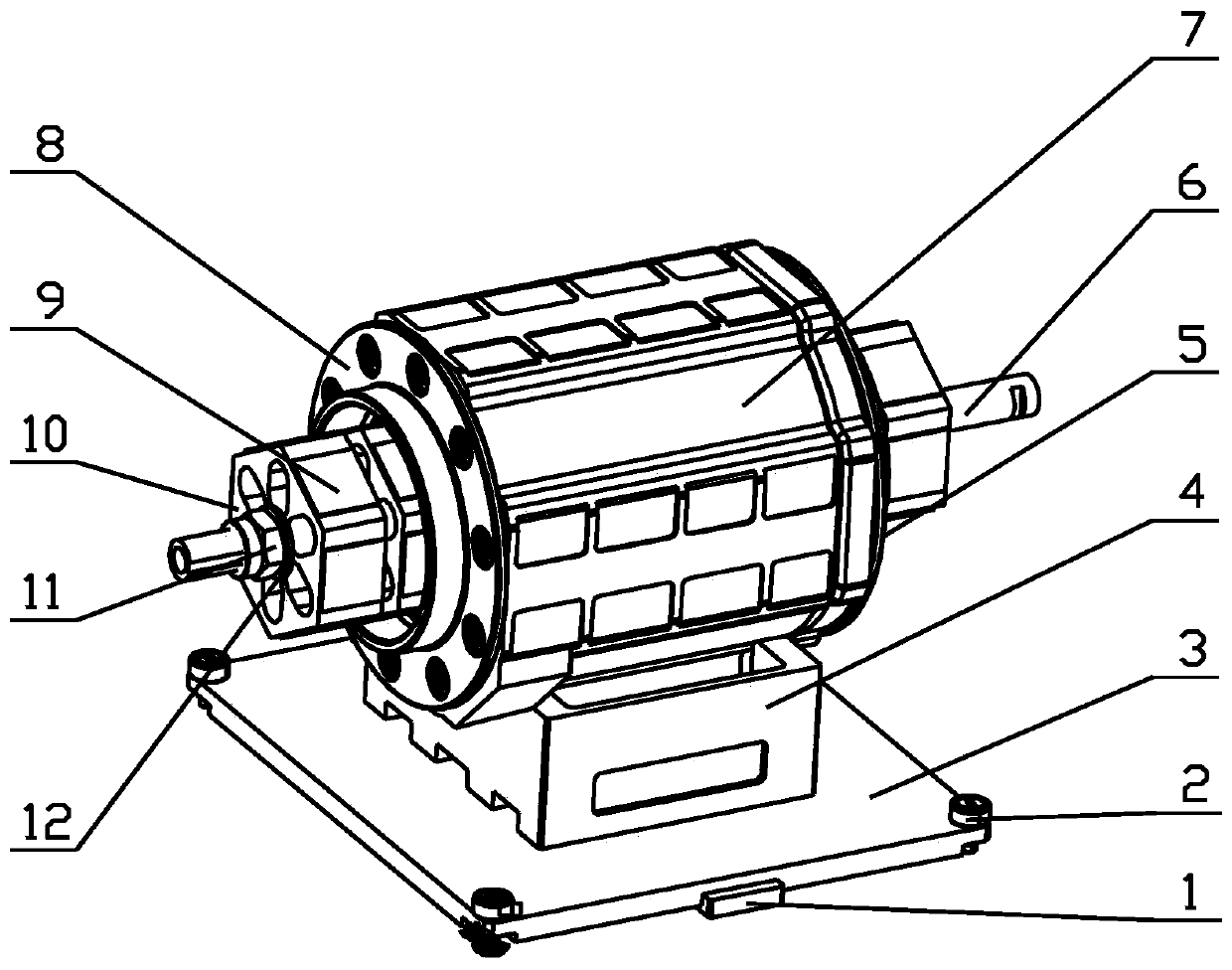

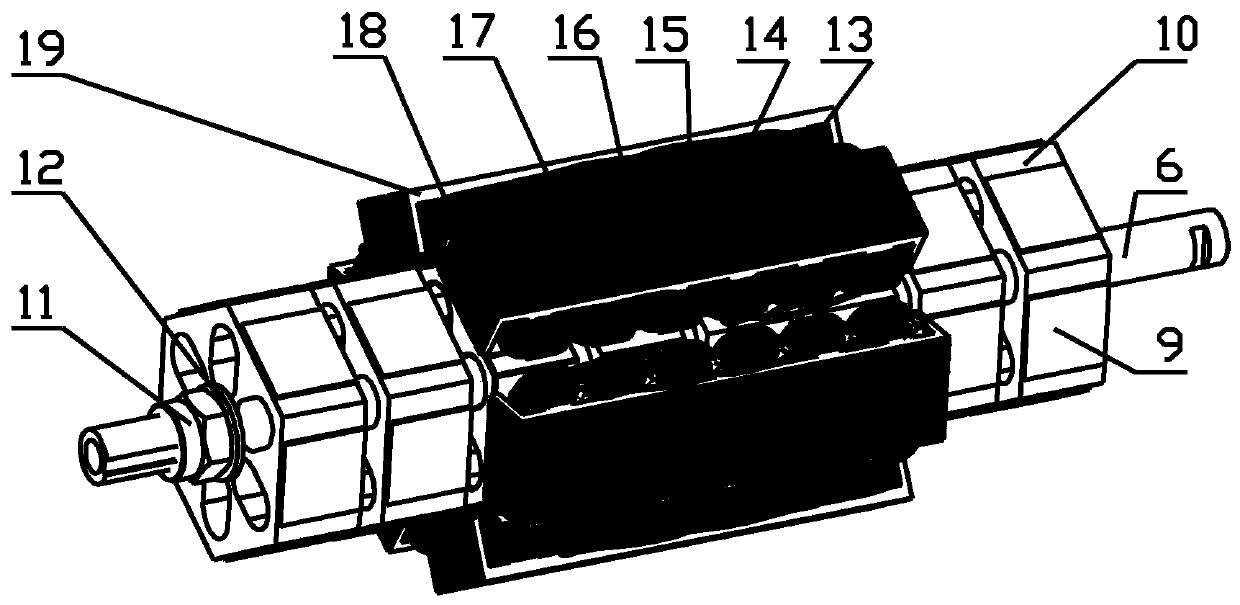

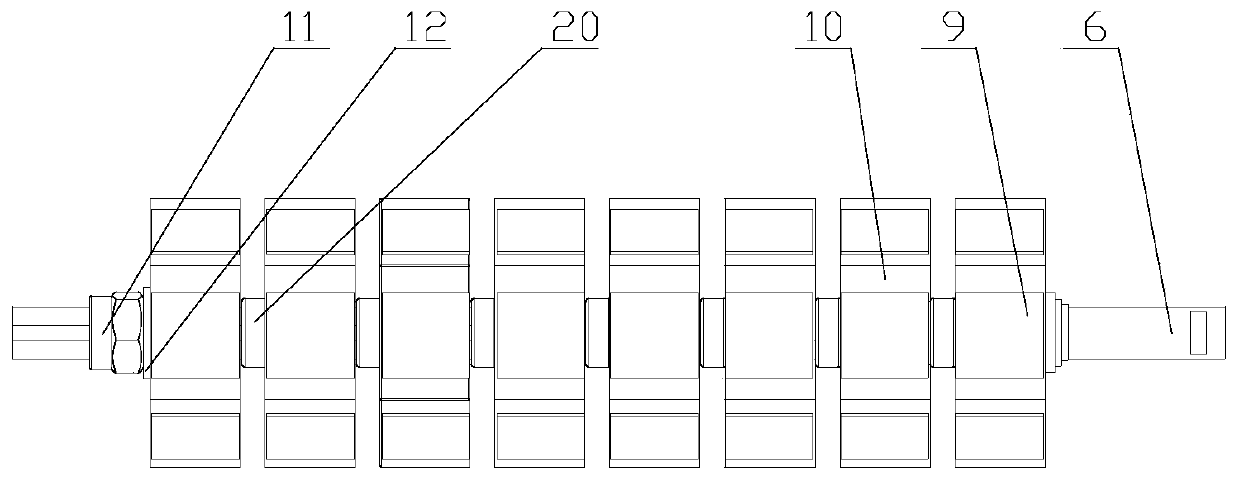

[0012] Embodiment of the present invention: a six-sided cylindrical fractional slot concentrated winding type active vibration absorber, including a vibration absorber frame 4, characterized in that a fixed bottom plate 3 is arranged under the vibration absorber frame 4, and four corners of the fixed bottom plate Set the fixing bolt 2, set the vibration isolation rubber pad 1 under the fixed bottom plate 3, set the heat dissipation shell 7 above the vibration absorber frame 4, set the dustproof left end cover 8 on the left end of the heat dissipation shell 7, and set the dustproof right end on the right end of the heat dissipation shell 7 Cover 5, silicon steel sheet 19 is arranged on the inner surface of heat dissipation shell 7, A-phase coil-18 is arranged on the first tooth of silicon steel sheet 19, B-phase coil-17 is arranged on the side of A-phase coil-18, and B-phase coil Set a C-phase coil 16 on the side of the first 17, set an A-phase coil 15 on the side of the C-phase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com