Concrete formwork reinforcement system and construction method

A technology of concrete formwork and formwork, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc. It can solve the problems of difficult installation and high quality of reinforcement components, and achieve rapid splicing and rapid lifting of sleeves Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

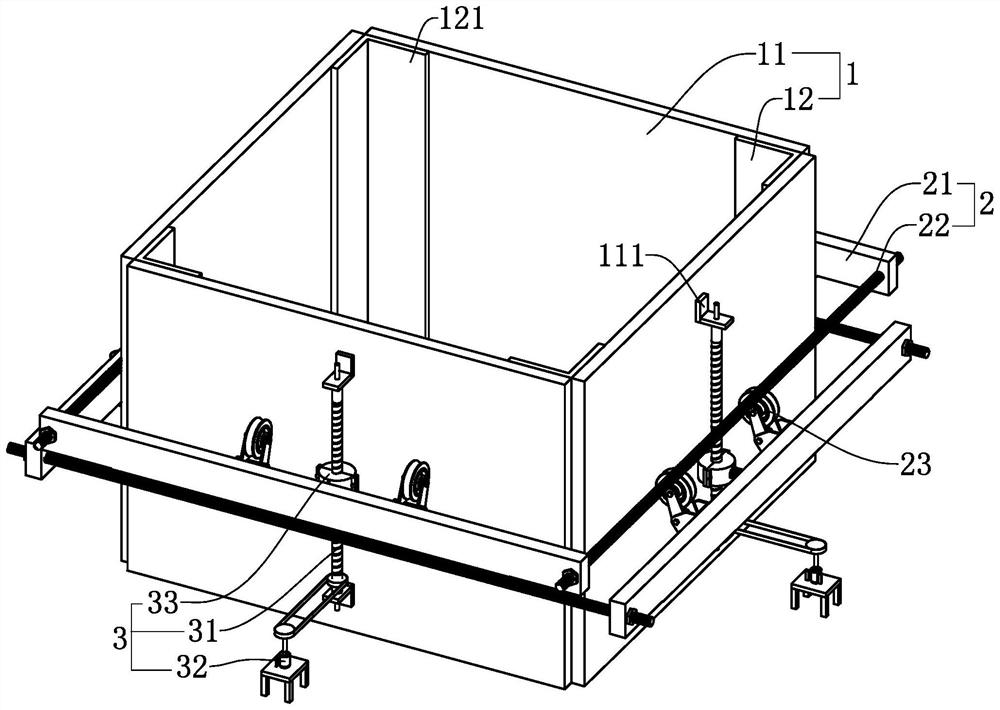

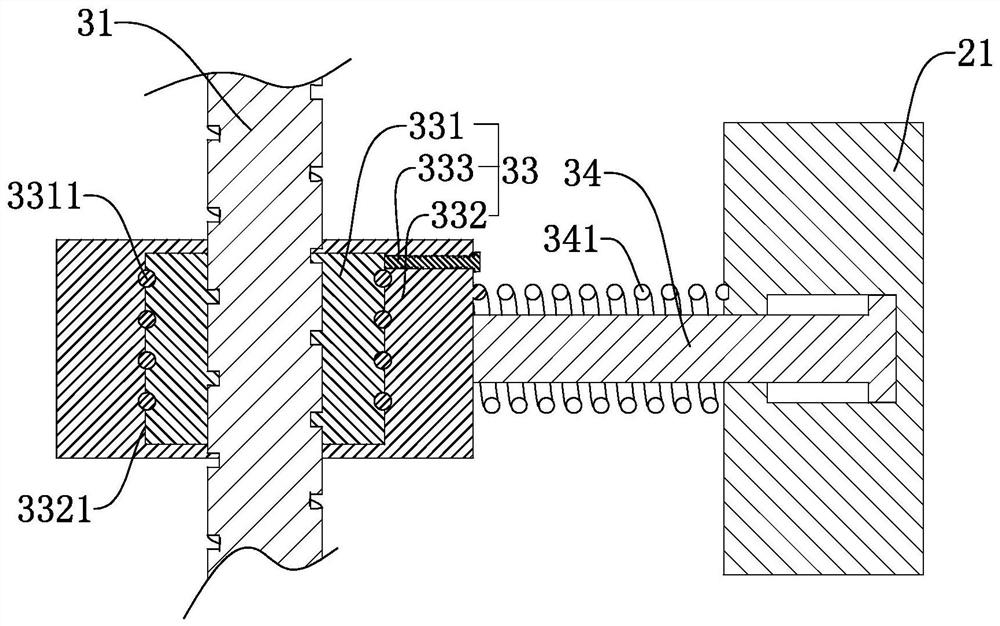

[0031] Such as figure 1 As shown, the present invention introduces a concrete formwork reinforcement system, including a formwork assembly 1, a reinforcement assembly 2 and a lifting assembly 3, the formwork assembly 1 forms a concrete pouring space, and the reinforcement assembly 2 is used to carry out the formwork assembly 1 Reinforcement, the reinforcement assembly 2 has multiple groups, and the formwork assembly 1 is fixed at different heights of the formwork assembly 1 to ensure the stability of the formwork assembly 1, while the lifting assembly 3 is located between the formwork assembly 1 and the reinforcement assembly 2. Then the reinforcement component 2 is lifted relative to the template component 1 . In this way, the reinforcement assembly 2 can be assembled at a low place close to the ground, and then the reinforcement assembly 2 can be lifted to a reasonable position by using the lifting assembly 3, and finally the reinforcement assembly 2 is fastened to fix the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com