A mixing device for rubber and plastic mixed polymer materials

A technology of polymer materials and stirring devices, which is applied in the field of polymer rubber and plastic products, and can solve problems such as the inability to change the degree of stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

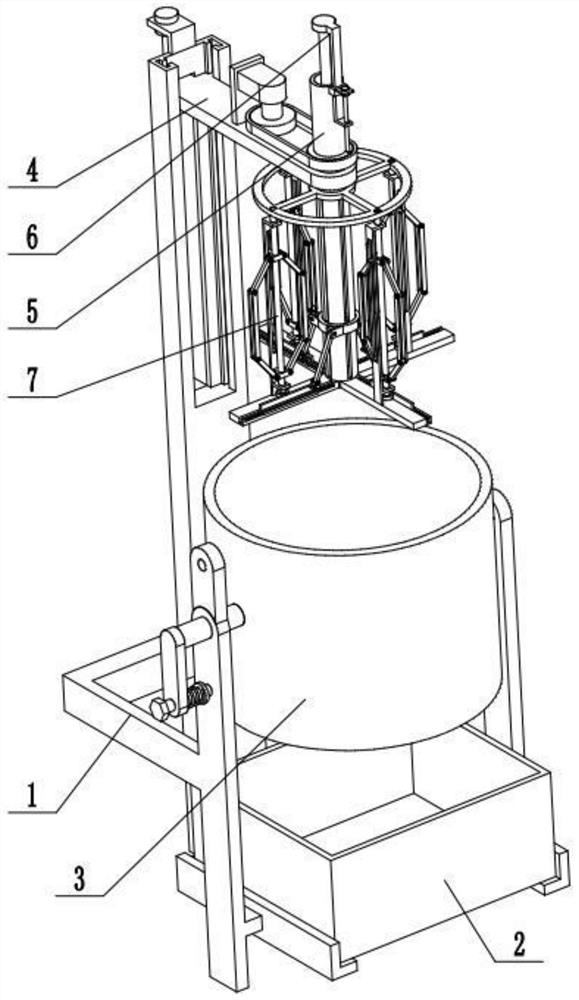

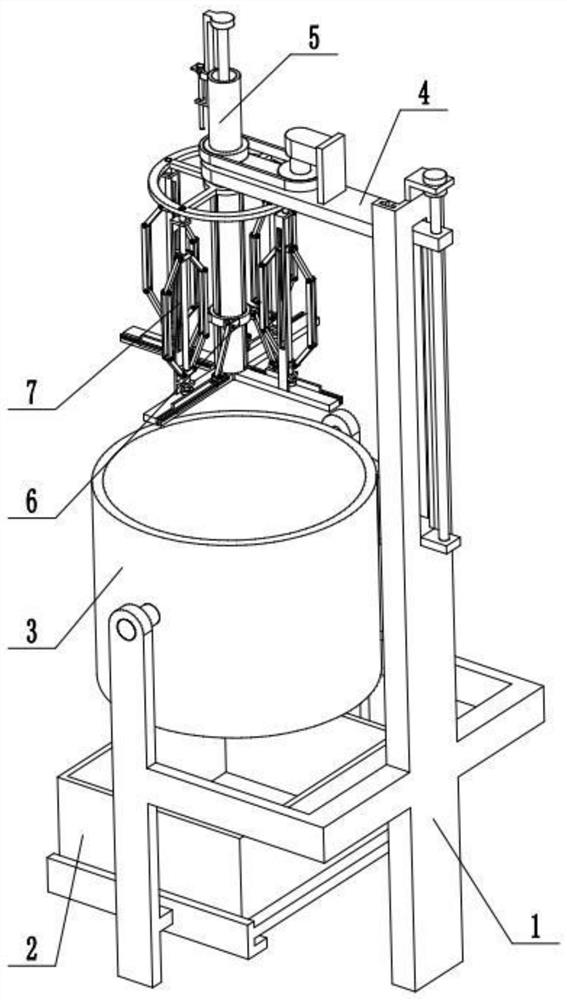

[0028] Combine below Figure 1-8Description of this embodiment, a mixing device for rubber and plastic mixed polymer materials, including a frame 1, a collection box 2, a mixing drum assembly 3, a height adjustment frame 4, a stirring drive device 5, an adjustment assembly 6 and an auxiliary stirring device 7. The collection box 2 described above is placed on the lower end of the frame 1, the mixing drum assembly 3 is arranged at the middle end of the frame 1, the collecting box 2 is located below the mixing drum assembly 3, and the height adjustment frame 4 is arranged on the upper end of the frame 1, and the stirring The driving device 5 is arranged on the front end of the height adjustment frame 4, the adjusting assembly 6 is arranged on the stirring driving device 5, the mixing drum assembly 3 is located under the stirring driving device 5, and four auxiliary stirring devices 7 are arranged, and the four auxiliary stirring devices 7 The upper end of the upper end is evenly...

specific Embodiment approach 2

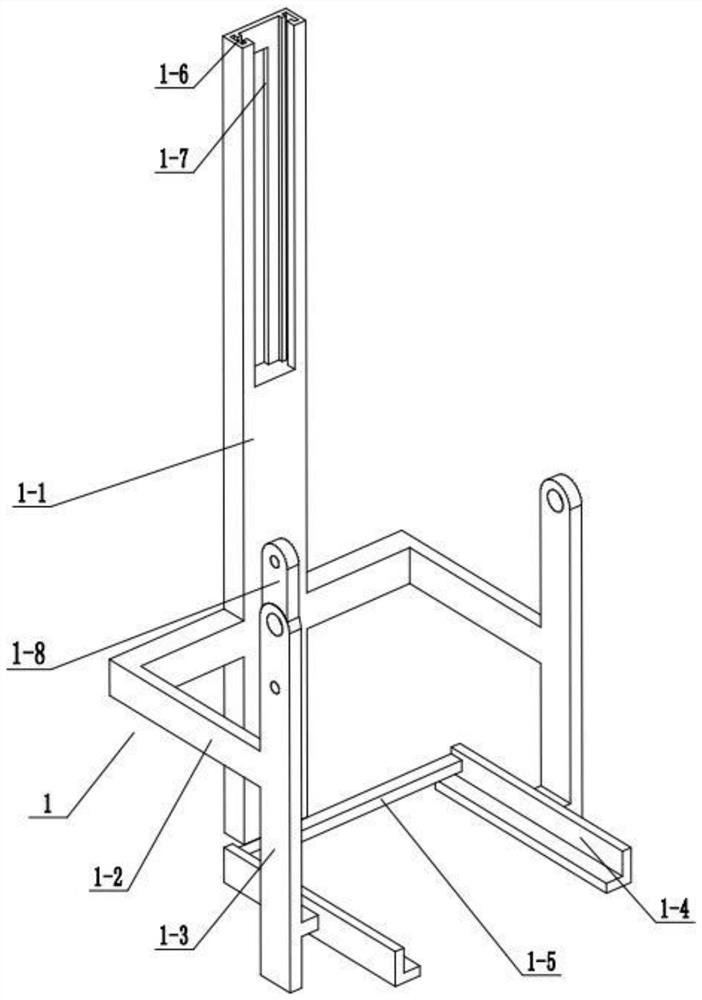

[0030] Combine below Figure 1-8 To illustrate this embodiment, the frame 1 includes a vertical frame plate 1-1, a door-shaped frame 1-2, a front frame plate 1-3, an L-shaped frame 1-4, a rear baffle plate 1-5, and a T-shaped frame. Chute 1-6, rectangular hole 1-7 and positioning frame 1-8; the lower end of the vertical frame plate 1-1 is fixedly connected to the door frame 1-2, and the two ends of the door frame 1-2 are all fixedly connected to a The front shelf 1-3, the upper end of the left front shelf 1-3 is fixedly connected to the positioning frame 1-8, the upper end of the left front shelf 1-3 and the positioning frame 1-8 are all provided with a jack, The inner sides of the two front frame plates 1-3 are fixedly connected to an L-shaped frame 1-4, and the rear ends of the two L-shaped frames 1-4 are fixedly connected to the rear baffle plate 1-5; The upper end is provided with a rectangular chute, and both sides of the rectangular chute are provided with a T-shaped ch...

specific Embodiment approach 3

[0032] Combine below Figure 1-8 To illustrate this embodiment, the mixing drum assembly 3 includes a mixing drum 3-1, a rotating shaft 3-2, a rotating rod 3-3, an insert rod 3-4, a pull plate 3-5, a spring seat 3-6 and a compression spring 3-7; both ends of the mixing drum 3-1 are fixedly connected to a rotating shaft 3-2, and the two rotating shafts 3-2 are respectively connected to the two front frame plates 1-3 through bearings with seats, and the rotating shaft 3-2 on the left is -2 is fixedly connected to the rotating rod 3-3, the middle part of the insertion rod 3-4 is slidably connected to the rotating rod 3-3, and the pull plate 3-5 and the spring seat 3-6 are respectively fixedly connected to the center of the insertion rod 3-4. At both ends, the insertion rod 3-4 is sleeved with a compression spring 3-7, and the two ends of the compression spring 3-7 are respectively fixedly connected to the rotating rod 3-3 and the spring seat 3-6, and the inner side of the inserti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com