A joint calibration method between 3D lidar and manipulator of mobile robot

A 3D laser, mobile operation technology, applied in the direction of manipulators, manufacturing tools, etc., can solve problems such as the inability to meet the three-dimensional environment perception of mobile operation robots, the inability of two-dimensional lasers to complete three-dimensional environment perception, and the influence of calibration results, to reduce dependence and improve. The effect of calibration accuracy and simple calibration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

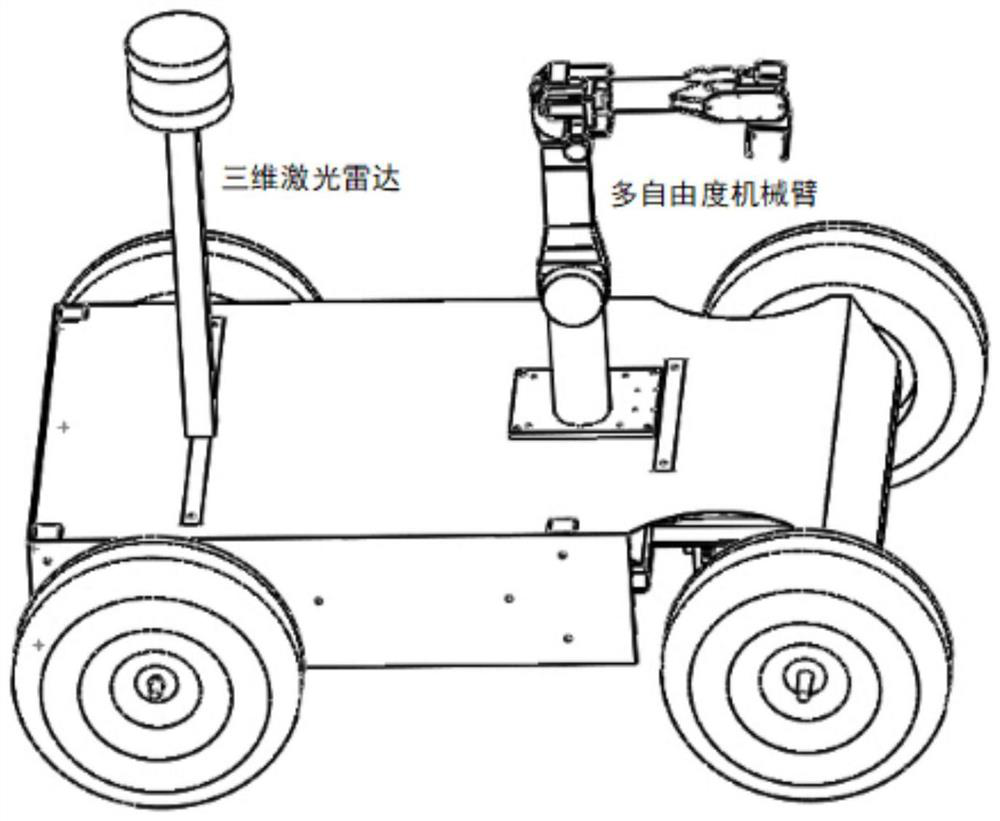

[0050] The three-dimensional laser radar used in the specific implementation process of the present invention is the 16-line laser VLP-16 of Velodyne Company, the robotic arm is the 6-DOF robotic arm SRQ05A-6D and its corresponding controller, and the square cardboard held by the end of the robotic arm is a square Cardboard with a side length of 10 cm. The method proposed in the present invention is also suitable for 32-line, 64-line or other specifications of three-dimensional lidar, as well as other degrees of freedom of the manipulator.

[0051] Take the text invention of 3D lidar and robotic arm as an example, especially the 16-line 3D laser and 6-axis robotic arm. The horizontal scanning angle of the 3D laser is 360 degrees, the vertical scanning angle is ±15 degrees, the scanning frequency is 10 Hz, and about 300,000 point cloud data are collected per second; the 6-axis robotic arm has 6 degrees of freedom, the payload is 5kg, and the joints run The speed can reach 180°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com