Metal plate repair gun

A sheet metal and gun body technology, applied in the field of sheet metal repair guns, can solve the problems of hidden safety hazards and low efficiency of construction personnel, and achieve the effect of improving construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further elaborated below in conjunction with the drawings and specific embodiments.

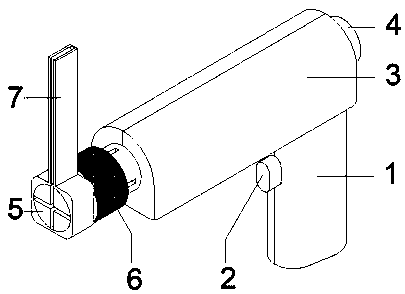

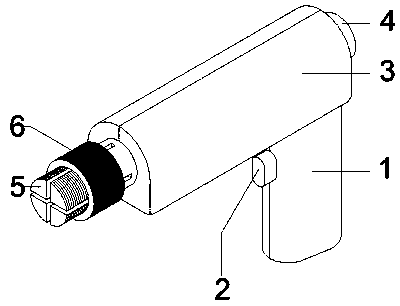

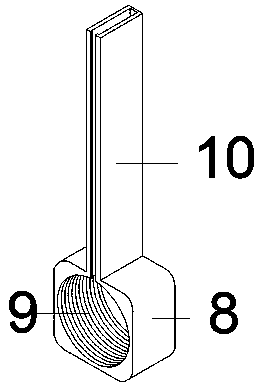

[0016] Such as figure 1 , figure 2 As shown, a sheet metal repair gun includes a grip 1, a power switch 2, a gun body 3, a cable interface 4, a gun head 5, a fixing ring 6, and a nail clip 7. The power switch 2 is mounted on the grip by screws 1 The upper part of the front side, and the top of the grip 1 is provided with an integrated gun body 3, the cable interface 4 is embedded in the rear end of the gun body 3, and the gun head 5 is embedded in the front end of the gun body 3 and fixed on the Inside the gun body 3, the fixed ring 6 and the nail clip 7 are installed on the gun head 5 in sequence through threads.

[0017] On the basis of the above technical solution, the gun head 5 is made of copper material, and is cut with a "cross" slot, which facilitates the pull ring meson to enter the slot under the action of gravity and contact the gun head 5.

[0018] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com