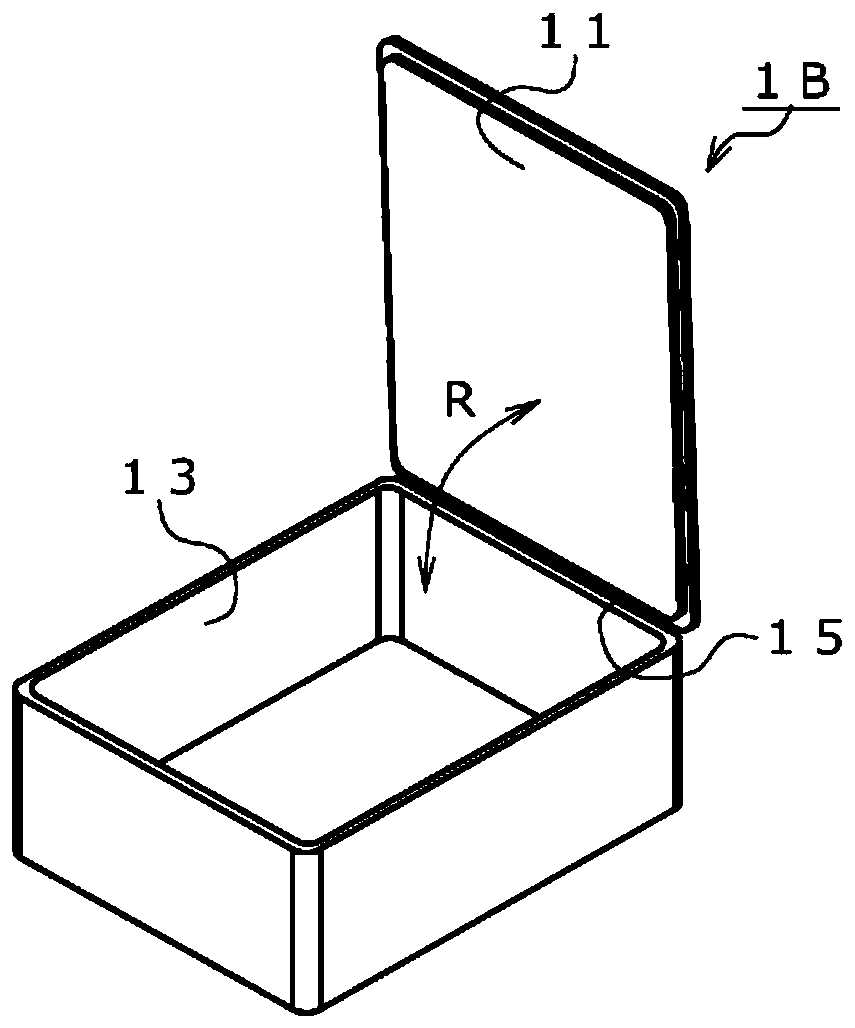

Molded article and method for producing same

A manufacturing method and technology of molded objects, applied to the field of molded objects and their manufacture, can solve the problems of increased installation space, increased cost, and more raw materials used, and achieve the effect of increasing the degree of freedom in design and reducing man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0161] Hereinafter, the present invention will be specifically described based on examples.

[0162] [1] Preparation of thermoplastic resin composition

[0163] (1) The thermoplastic resin composition of Example 1

[0164] After dry mixing the following polyamide resin pellets and the following modified elastomer pellets, they were put into a twin-screw melting and kneading extruder, and melted and kneaded at a kneading temperature of 210°C. pellet machine to obtain pellets formed by melt kneading of polyamide resin and modified elastomer. Furthermore, the above-mentioned pellets (pellets formed by melting and kneading a polyamide resin and a modified elastomer) were dry-blended with pellets of the following polyolefin resin, and then put into a twin-screw melt-kneading extrusion Melt kneading at a kneading temperature of 210° C. using a pelletizer to obtain pellets made of a thermoplastic resin composition.

[0165] The compounding ratio of the polyolefin resin, the polyam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Charpy impact strength | aaaaa | aaaaa |

| Charpy impact strength | aaaaa | aaaaa |

| Charpy impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com