Global optimization method for cutter-axis vector based on minimum angular acceleration of machine tool rotating shaft

An angular acceleration and global optimization technology, applied in the direction of instruments, digital control, control/adjustment systems, etc., can solve the problems of difficult control of the tool axis, time-consuming and labor-intensive calculation, unfavorable overall smoothness of the tool axis vector, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The specific embodiment of the present invention will be described in detail in conjunction with the technical scheme and the accompanying drawings

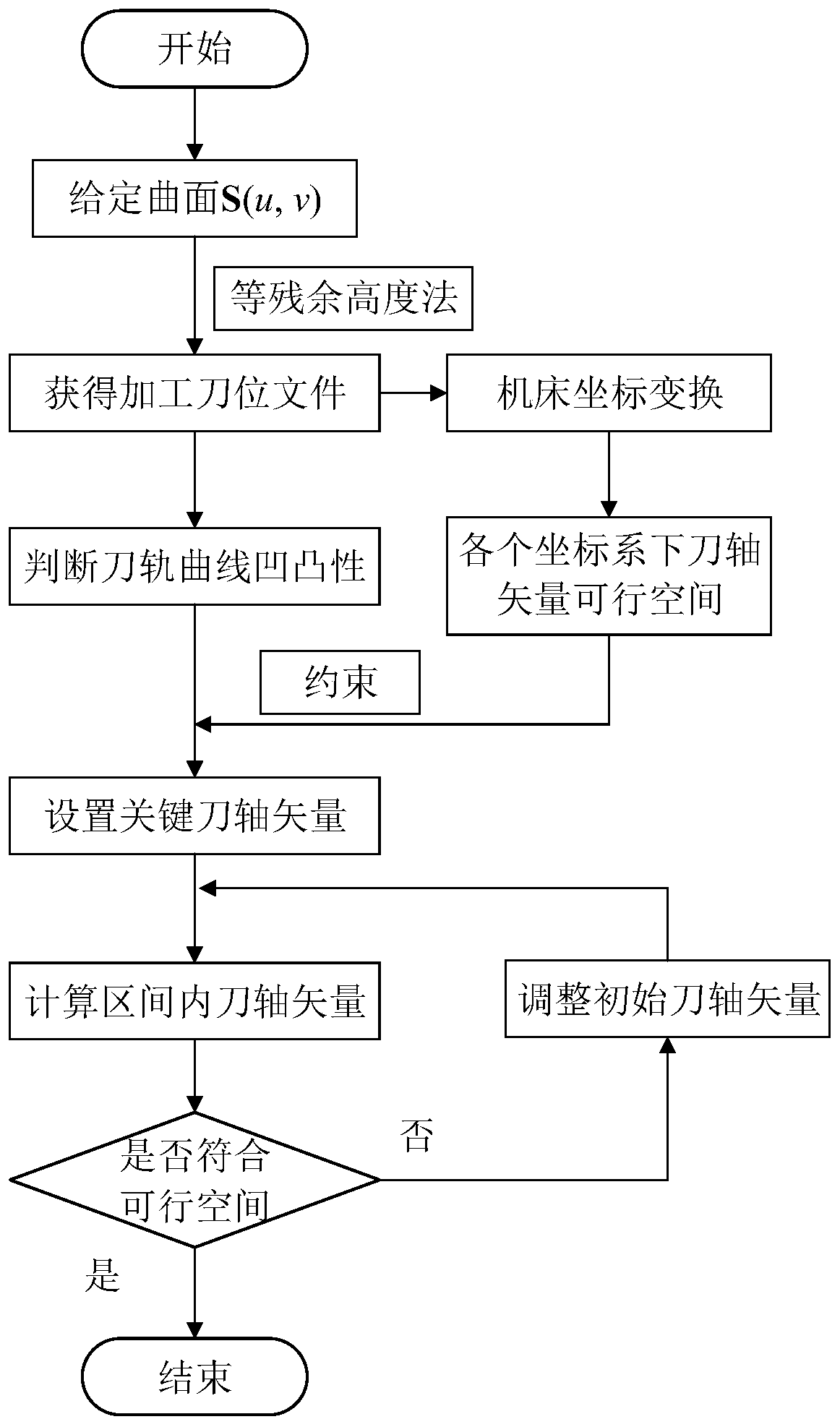

[0080] In the process of five-axis CNC machining of complex curved surfaces, reasonable planning of the tool axis vector can avoid the sudden change in the motion of the machine tool's rotary feed axis and affect the quality of the machined surface. The method has the problem that too many optimization intervals make it difficult to optimize the tool axis vector. A global optimization method for surface machining tool vector based on the minimum angular acceleration of the machine tool rotation axis is invented. The flow of the method is shown in Figure 1.

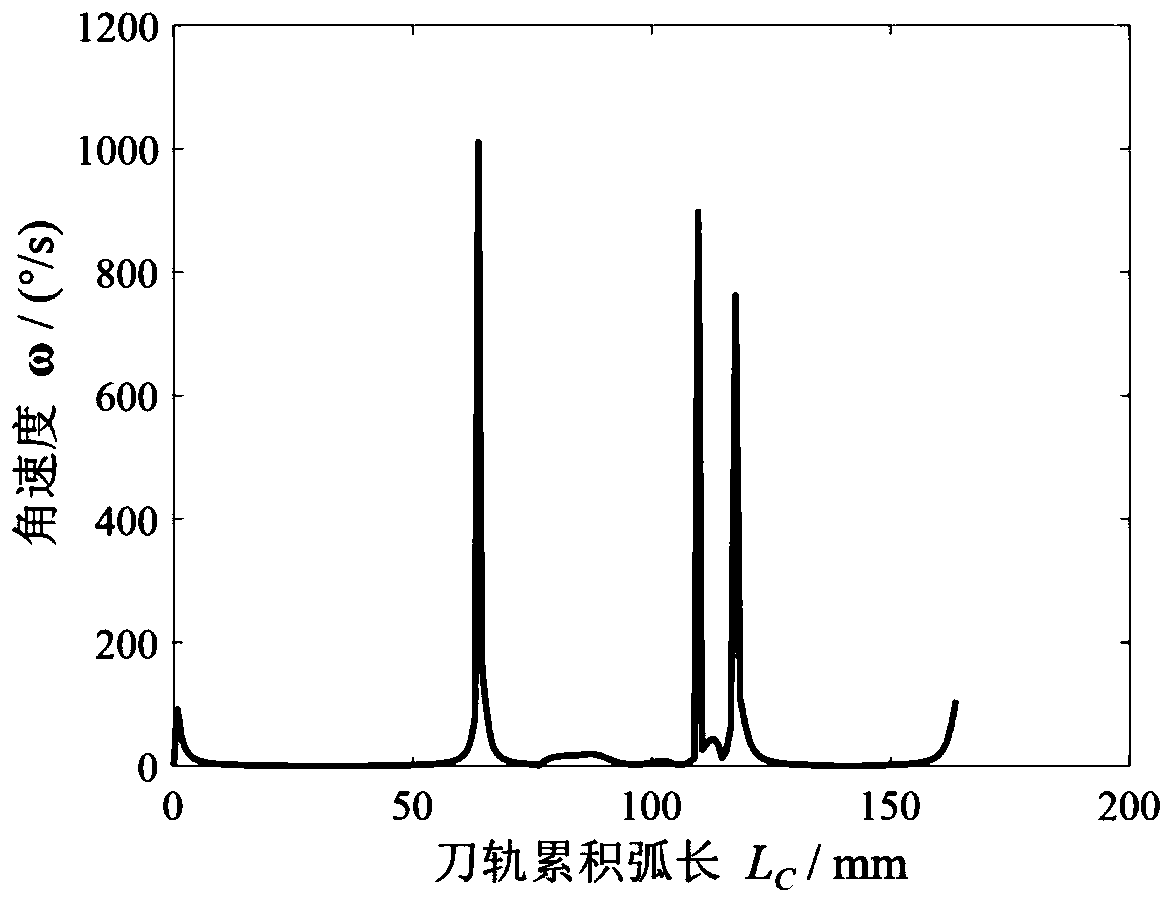

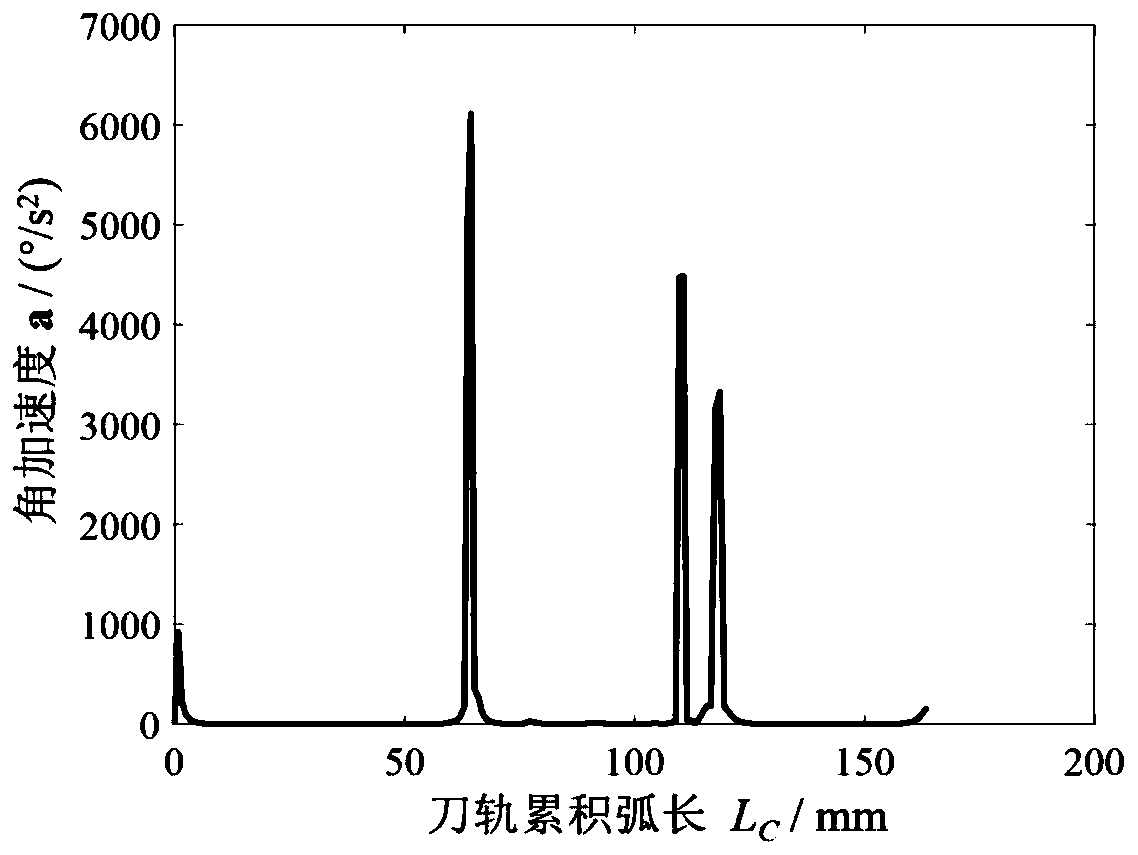

[0081] Taking the milling sinusoidal surface parts with a ball-end milling cutter with a diameter of 6 mm in an AC double turntable five-axis CNC machine tool as an example, with the help of UG software and MATLAB mathematical tools, the specific implementation process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com