A method and device for detecting the rotational speed of a rotating anode bulb tube rotor

A rotor speed and rotating anode technology, which is applied to devices using electric/magnetic methods, measuring devices, linear/angular velocity measurements, etc., can solve problems such as inability to detect rotor speed in real time, reading errors, and difficulty in rotor speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

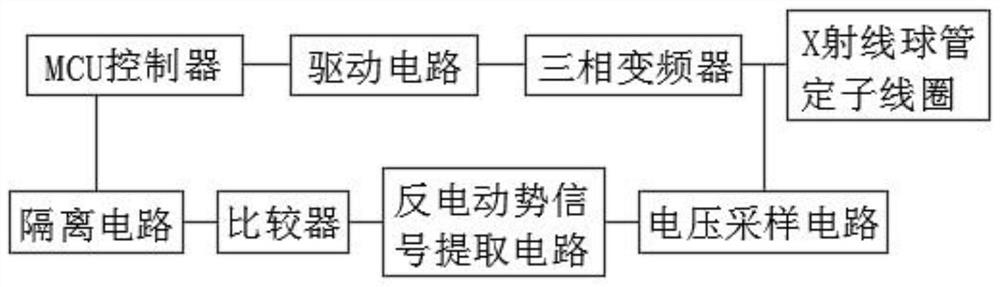

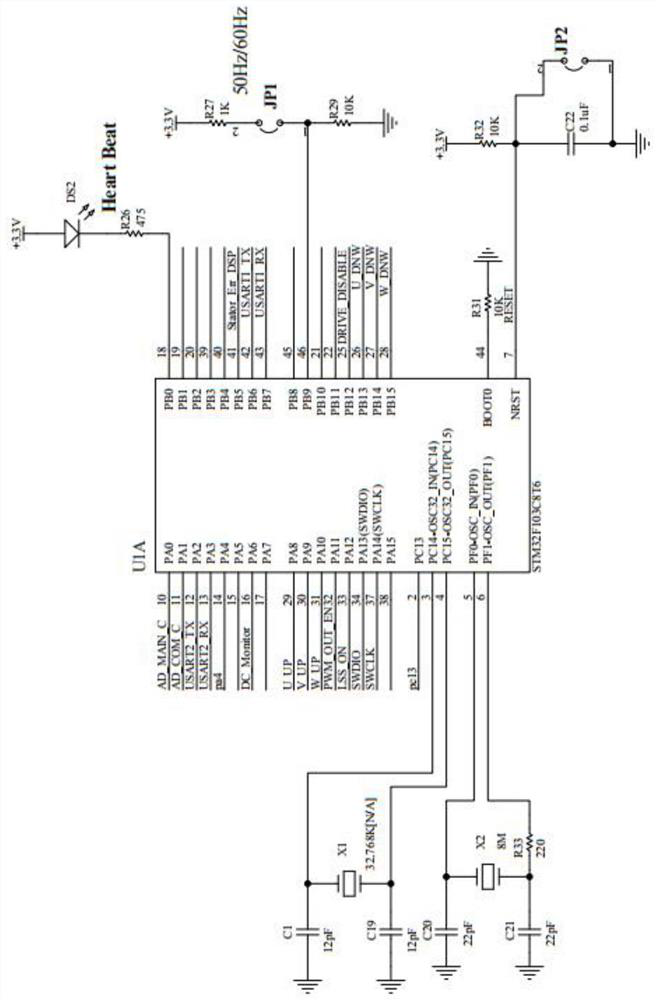

[0036] See Figure 1-7 One embodiment of the present invention is provided: a rotor speed detection method of rotary anode ball tube, including the following steps:

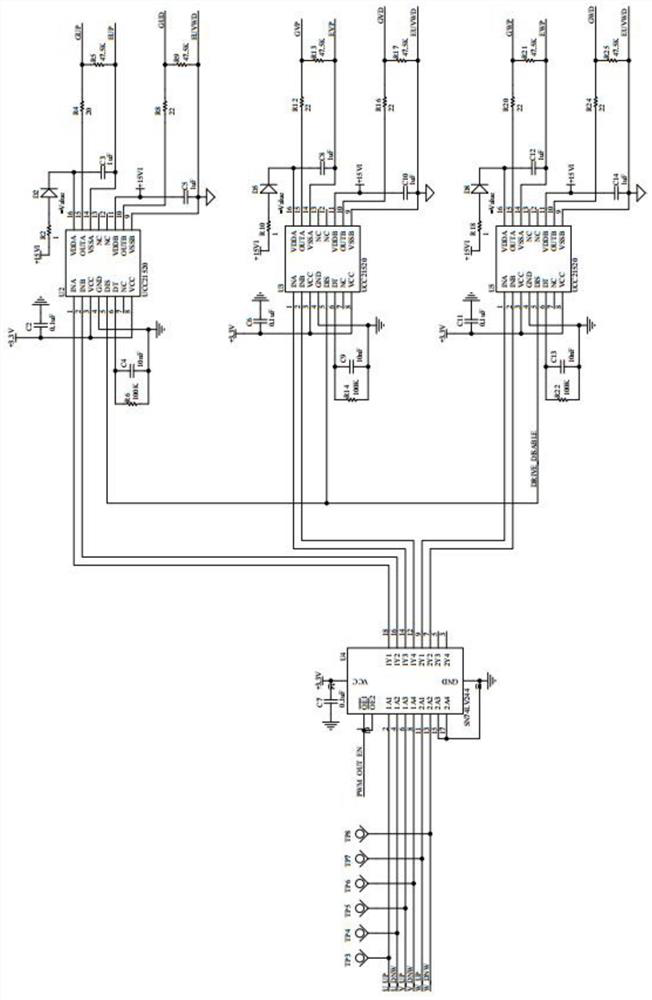

[0037] S1: The MCU controller generates a SPWM control sequence between the control algorithm to drive the three-phase frequency converter to generate a corresponding AC output;

[0038] S2: Three AC outputs of the three-phase frequency converter are terminally connected to the X-ray tube stator coil to drive the X-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com