Layered rotary cutting test device and test method for adhesion near interface with volume change being restrained

A testing device and testing method technology, applied in the direction of measuring device, using stable torsional force to test material strength, using stable shear force to test material strength, etc. Problems such as position and stress state, inability to control the depth of rotary cutting to keep constant, etc., to achieve the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

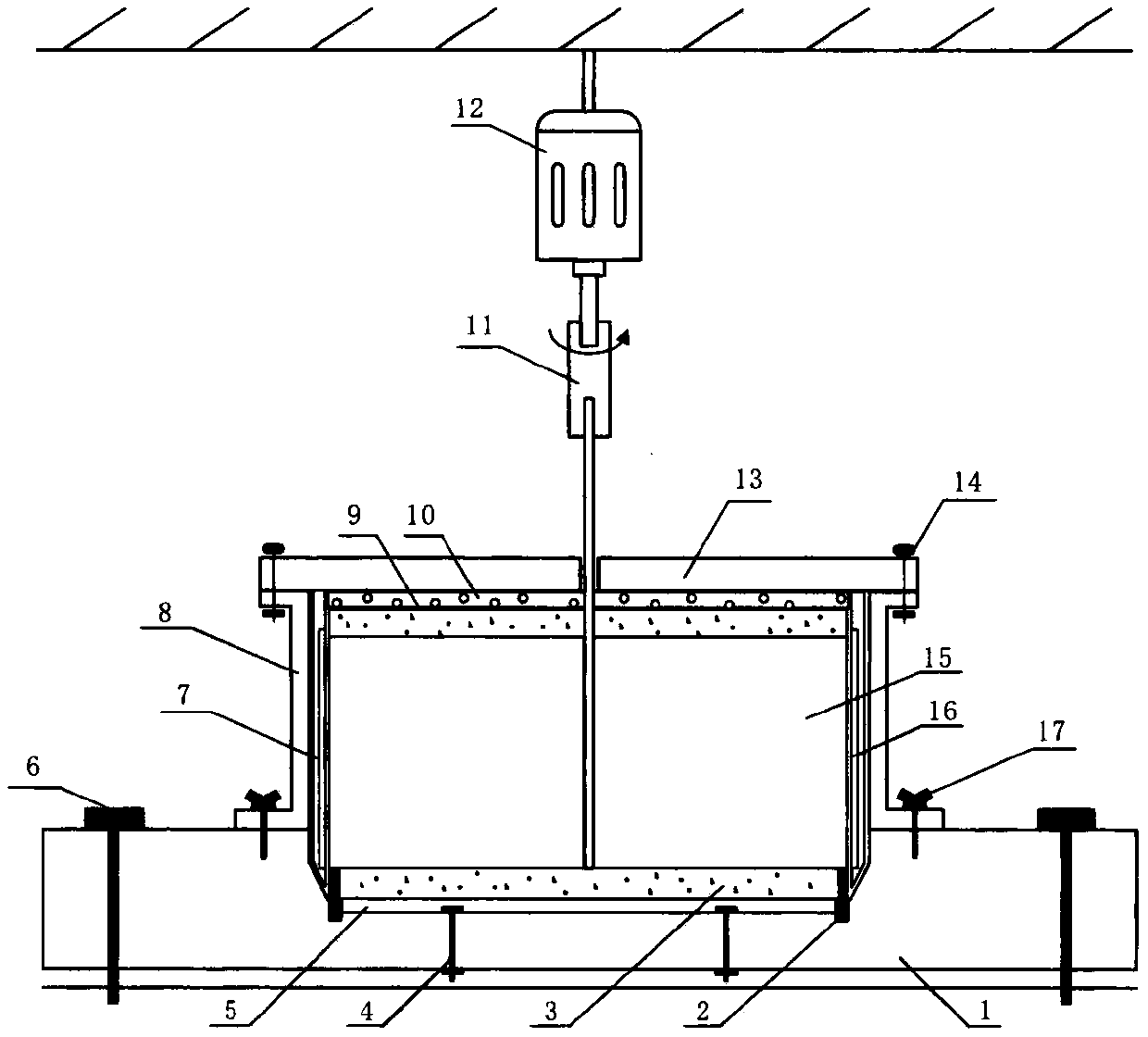

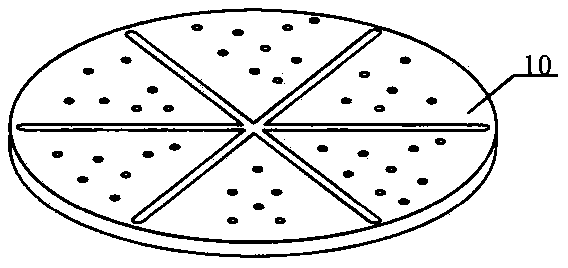

[0031] A kind of adhesion force layering rotary cutting test device near the interface of constrained volume change (such as figure 1 ), including grooved base 1, metal washer 2, soil sample 3, pin 14, metal bottom plate 5, bolt 6, ring knife 7, wall protection cylinder 8, filter paper 9, permeable plate 10, torque meter 11, drive power supply 12. The pressure cover plate 13, the pin bolt II 14, the rotary cutting plate 15, the sliding ring 16 and the pin bolt III 17 are jointly composed;

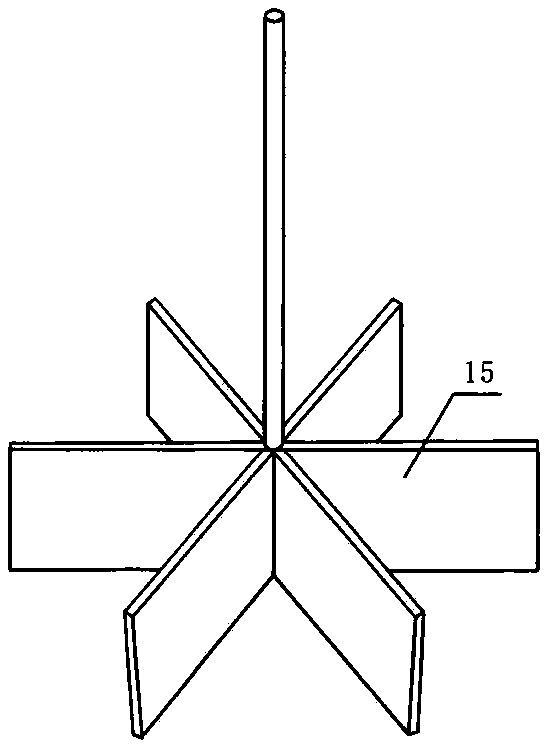

[0032] Rotary cutting plate 15 (such as figure 2 ) side close to ring knife 7 inside sliding ring 16 (such as Figure 4 ), which eliminates the adhesion resistance of the ring knife to the rotary cutting plate (15) during rotary cutting, and the angle between the blades is small. After the rotary cutting is completed, a large amount of soil can be taken away to cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com