Method for precisely measuring gas slippage coefficient of low-permeability coal seam

A slippage coefficient, precise measurement technology, applied in the direction of measuring device, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problems of large error of slippage coefficient and inability to accurately predict the law of gas migration in low-permeability coal seams, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

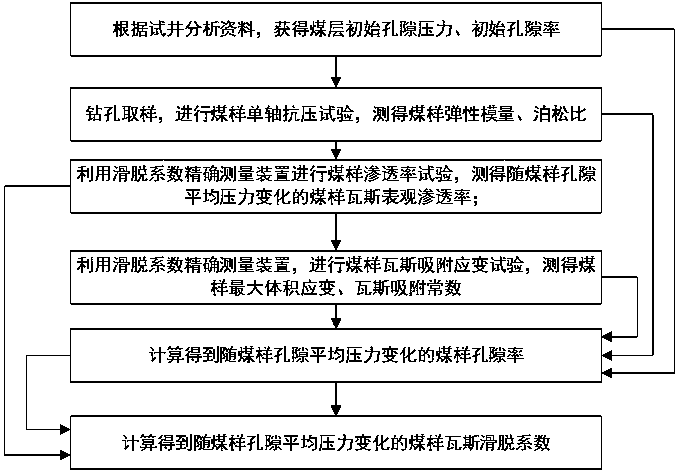

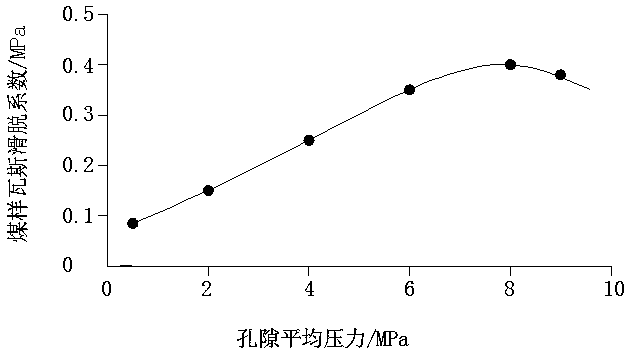

[0034] The specific implementation of a method for accurately measuring the gas slippage coefficient of low-permeability coal seams is as follows:

[0035] (1) According to the well test analysis data of a coalbed methane well, the average initial pore pressure of the coal seam is 9.5MPa and the initial porosity is 0.3%;

[0036] (2) The coal seam is drilled and sampled, the size of the coal sample is φ50×100mm, a total of 10, numbered 1 #~11 # . take 1 # ~10 # Carry out uniaxial compressive test, measure its elastic modulus, Poisson's ratio, take the average value, obtain elastic modulus of 2050MPa, Poisson's ratio of 0.4;

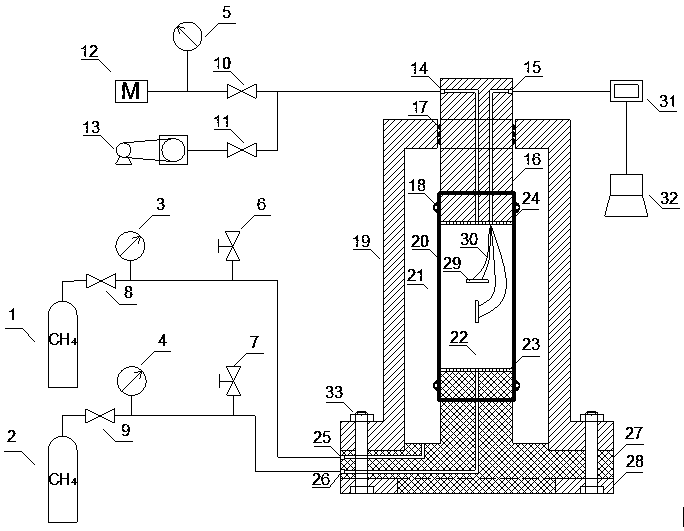

[0037] (3) Using an accurate measurement device for the gas slippage coefficient of low-permeability coal seams to 11 # The coal samples were subjected to the gas apparent permeability test.

[0038] ①Install the coal sample. The coal sample 22 is put into the sealing sleeve 20. The lower end of the coal sample 22 is connected to the metal base 27 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com