Paper wrapping device of test tube

A test tube and paper wrapping technology, which is applied in the directions of measuring devices, instruments, scientific instruments, etc., can solve the problems such as being unsuitable for large-scale and continuous testing, and low wrapping efficiency of test tube filter paper.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

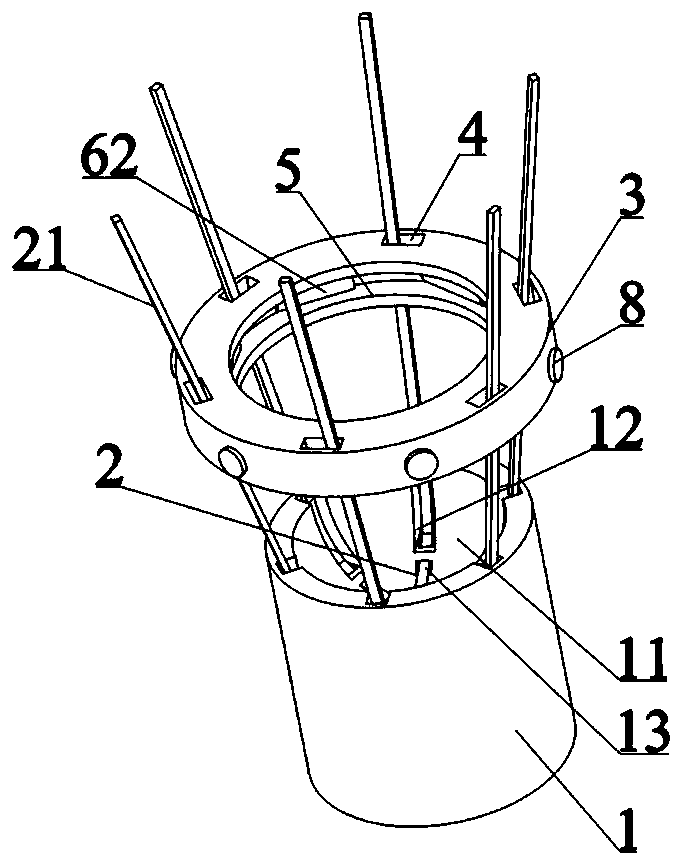

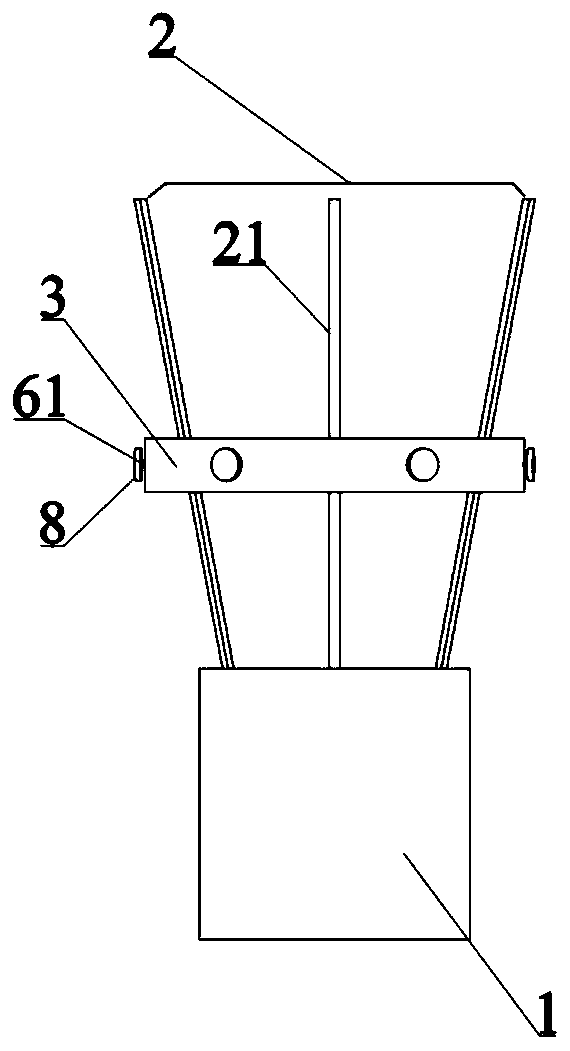

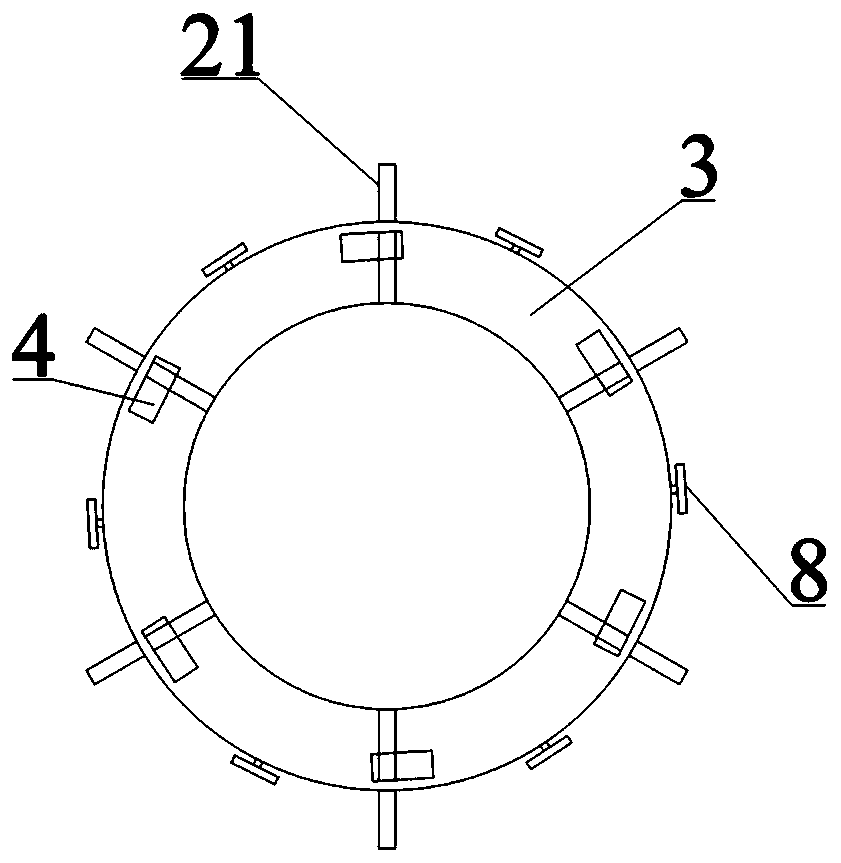

[0042] refer to Figure 1-7 , the present embodiment provides a test tube wrapping device, including a base, a shrink frame and a neck ring. The top of the base is provided with a bearing chamber matching the bottom of the test tube, the top of the bearing chamber is provided with support grooves evenly distributed along the periphery, and the bottom of the support groove is provided with a first through hole. As a further improvement of the present invention, the through hole is a through hole with an arc-shaped longitudinal section adapted to the support bar. The purpose of such a structure is to adapt to the extension of the shrink frame. As a further improvement of the present invention, the branch is made of polymer plastic material and its ends are hot-melt connected. This way is convenient for processing and making. As a further improvement of the present invention, elastic pieces are provided inside the support groove and at intervals between the support bars. As a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com