A dimethyl ether compression ignition rotary engine and its control method

A rotary engine, dimethyl ether technology, applied in engine control, combustion engine, internal combustion piston engine and other directions, can solve the problems of poor fuel economy, increased wall quenching, and high emissions, reducing concentration, improving combustion efficiency, and ignition energy. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

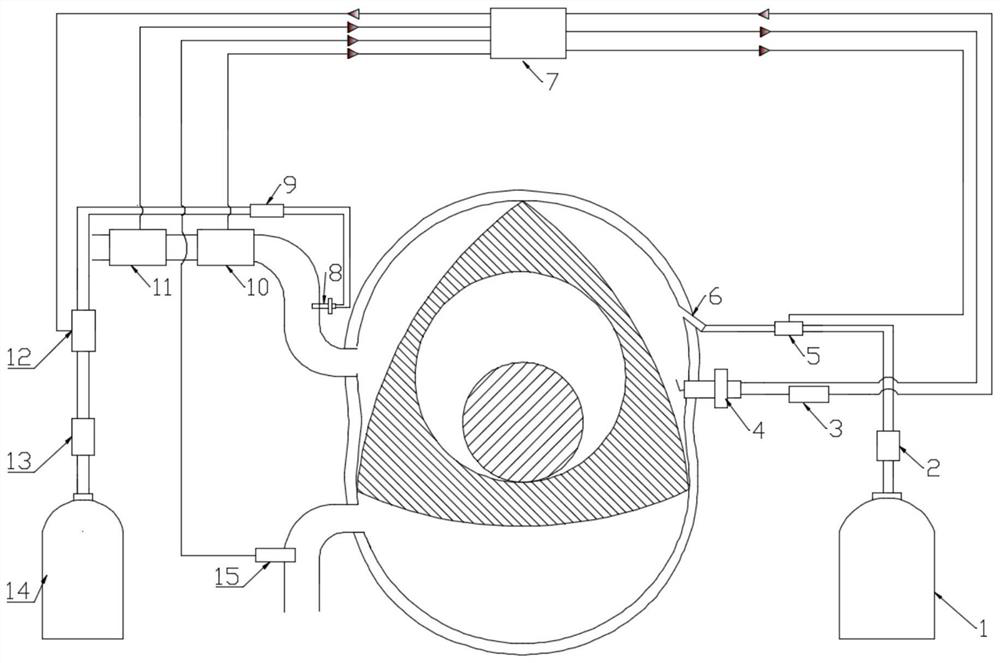

[0017] Such as figure 1 Including: fuel tank 1, when the gasoline nozzle 6 receives the fuel injection signal and opens, the fuel pump 2 pumps out the gasoline in the fuel tank 1, and sprays it into the combustion chamber through the gasoline flowmeter 5 from the nozzle. The spark plug type cylinder pressure sensor 4 detects pressure changes in the cylinder and simultaneously ignites the mixture in the cylinder, and the charge amplifier 3 is connected in series with it. The electronic control unit 7 regulates the ignition and fuel injection parameters. Intake pressure sensor 10 is connected in series with air flow meter 11 on the intake passage, intake pressure and temperature are monitored, also be equipped with dimethyl ether nozzle after intake pressure sensor 10, the fuel in the dimethyl ether fuel tank 14 After passing through the pressure red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com