Rectangular working well in water-rich stratum and preinstalling with pipe-jacking door opening and sliding-moving type rear-leaning wall and construction method of rectangular working well

A technology for water-rich strata and working wells, applied in water conservancy projects, artificial islands, pipe components, etc., can solve the problems of danger, difficult operation, and high risk of door openings, so as to overcome construction difficulties and safety risks, shorten construction period, and technical Idea Advanced Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

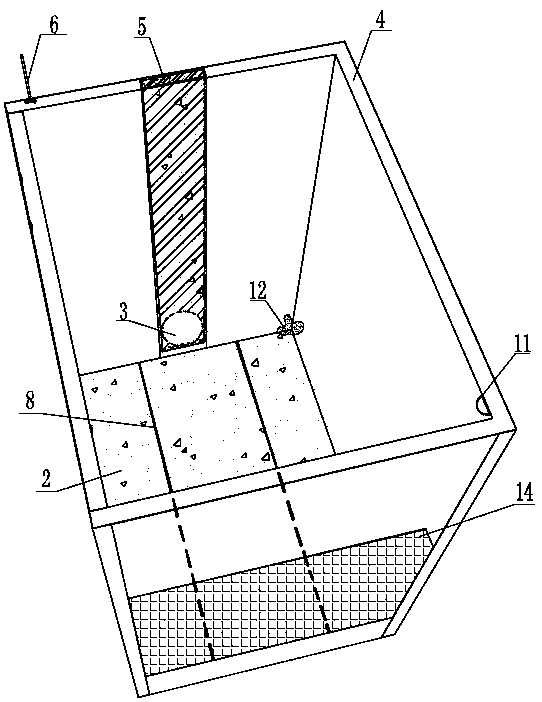

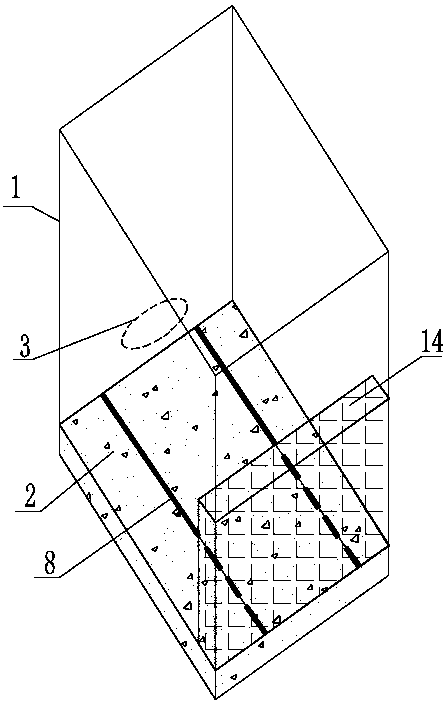

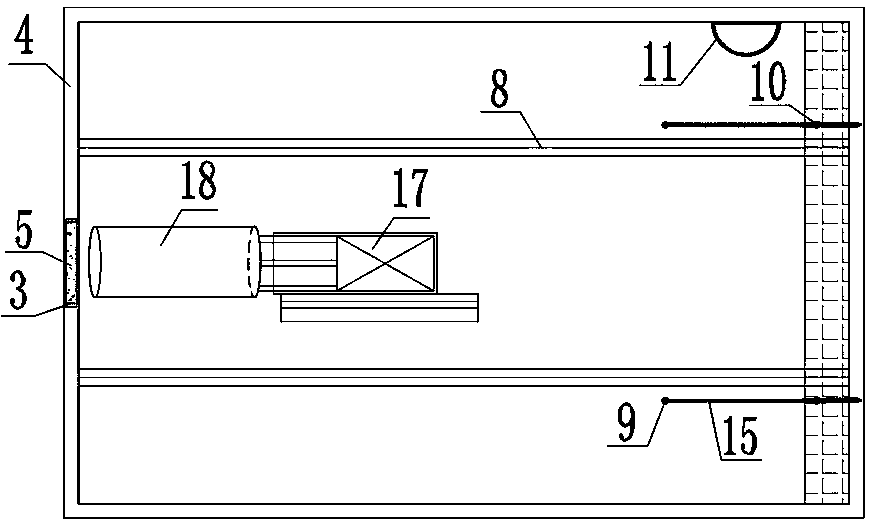

[0046] A construction method for a rectangular working well with preset pipe-jacking door openings and sliding back-to-wall in water-rich formations. Firstly, the functional requirements design of the rectangular pipe-jacking working well is completed; Earthwork excavation in the pipe jacking well, sealing the bottom of the rectangular pipe jacking well, and pre-buried sliding rails, pull rings and anchors against the wall behind; installation of ladders, joint leakage control and openings for entering the rectangular pipe jacking well Installation of the water-stop pressure plate; construction against the wall of the sliding type; and then the hydraulic jacking force of the pipe jacking equipment penetrates and lifts the sandwich concrete slab wall and opens the door opening to safely carry out the pipe jacking construction operation, that is It can complete the construction of preset pipe-jacking door openings in water-rich formations and rectangular pipe-jacking working well...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com