Starlight glazed ceramic tile and preparation method thereof

A technology of ceramic tiles and star glaze, applied in the field of ceramic tile preparation, can solve the problems of lack of unique new products, single presentation effect, serious homogenization phenomenon, etc., achieves good pattern definition, meets diverse needs, and is trendy decorative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of starlight glazed ceramic tile comprises the following steps:

[0029] (1) Press the powder into a green body, and dry the green body at 150°C for 1.5 hours;

[0030] (2) Clean the surface of the green body, and spray water on the surface of the green body to make the surface of the green body wet;

[0031] (3) Apply primer on the surface of the green body;

[0032] (4) Use screen printing color glaze, preferably use 100 mesh all-through screen;

[0033] (5) Inkjet printing pattern;

[0034] (6) Apply transparent bright dry granules on the brick surface, preferably evenly spread the transparent bright dry granules on the brick surface in the shape of sand;

[0035] (7) Put the green body in step (6) into a kiln for firing at a temperature of 1150°C and a firing time of 60 minutes;

[0036] (8) Softly polish the transparent bright dry particles protruding from the surface of the fired tiles to obtain starlight glazed ceramic tiles.

[0037] ...

Embodiment 2

[0042] The preparation method of starlight glaze ceramic tile is identical with embodiment 1.

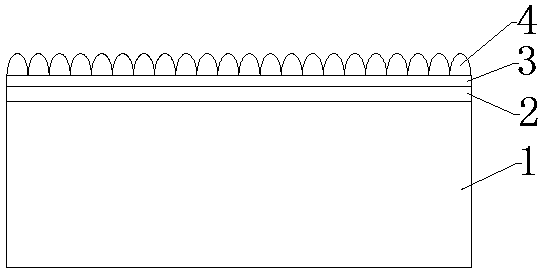

[0043] Starlight Glazed Porcelain Tiles, see figure 1 , including body layer 1, bottom glaze layer 2, chromogenic glaze layer 3 and dry granular glaze layer 4 from bottom to top.

[0044] Wherein, the transparent light dry granules used in the dry granule glaze layer include 38 parts by weight of potassium feldspar, 12 parts of burnt talc, 10 parts of calcite, 33 parts of quartz, 10 parts of barium carbonate, 10 parts of calcined alumina, 5 parts air knife soil and 3 parts zinc oxide. The preparation method of the transparent glossy dry granule is the same as that of Example 1.

[0045] The formula and preparation method of the bottom glaze are the same as in Example 1.

[0046] The formula and the preparation method of chromogenic glaze are identical with embodiment 1.

Embodiment 3

[0048] The preparation method of starlight glaze ceramic tile is identical with embodiment 1.

[0049] Starlight glazed ceramic tiles, from bottom to top, include body layer, bottom glaze layer, colored glaze layer and dry grain glaze layer.

[0050] Wherein, the transparent light dry granules used in the dry granule glaze layer include 38 parts by weight of potassium feldspar, 12 parts of burnt talc, 8 parts of calcite, 33 parts of quartz, 12 parts of barium carbonate, 10 parts of calcined alumina, 5 parts of air knife soil and 3 parts zinc oxide. The preparation method of the transparent glossy dry granule is the same as that of Example 1.

[0051] The formula and preparation method of the bottom glaze are the same as in Example 1.

[0052] The formula and the preparation method of chromogenic glaze are identical with embodiment 1.

[0053] The difference of embodiment 1,2,3 is that the proportioning of calcite and barium carbonate is different in the formula of transpare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com