Strontium carbonate forming and calcining process for preparing strontium oxide

A calcination process, a technology of strontium carbonate, applied in the direction of calcium/strontium/barium oxide/hydroxide, etc., can solve the problems of high cost of purchasing raw materials, high energy consumption and equipment maintenance costs, and inability to recycle, so as to reduce the labor of workers. Strength, avoidance of dust formation problems, and the effect of reducing procurement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

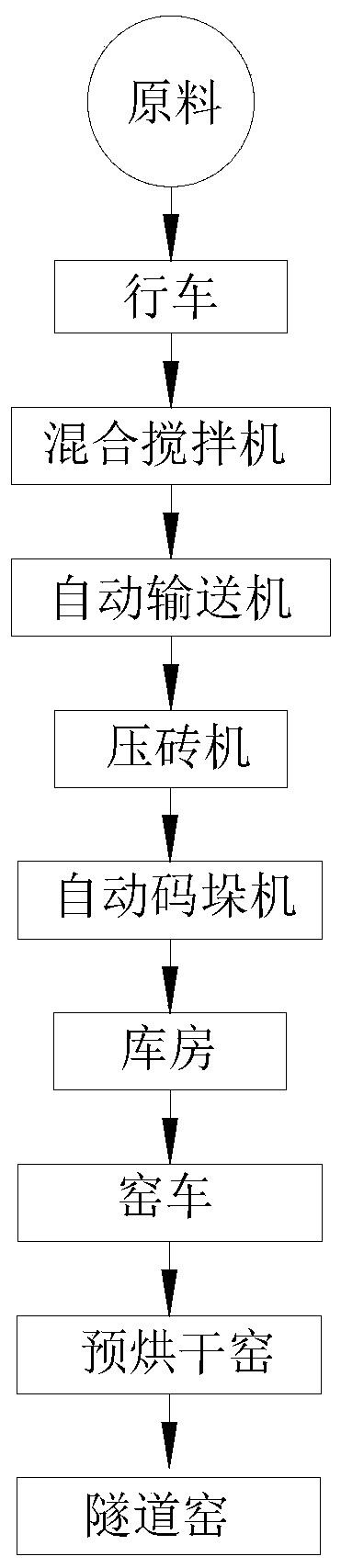

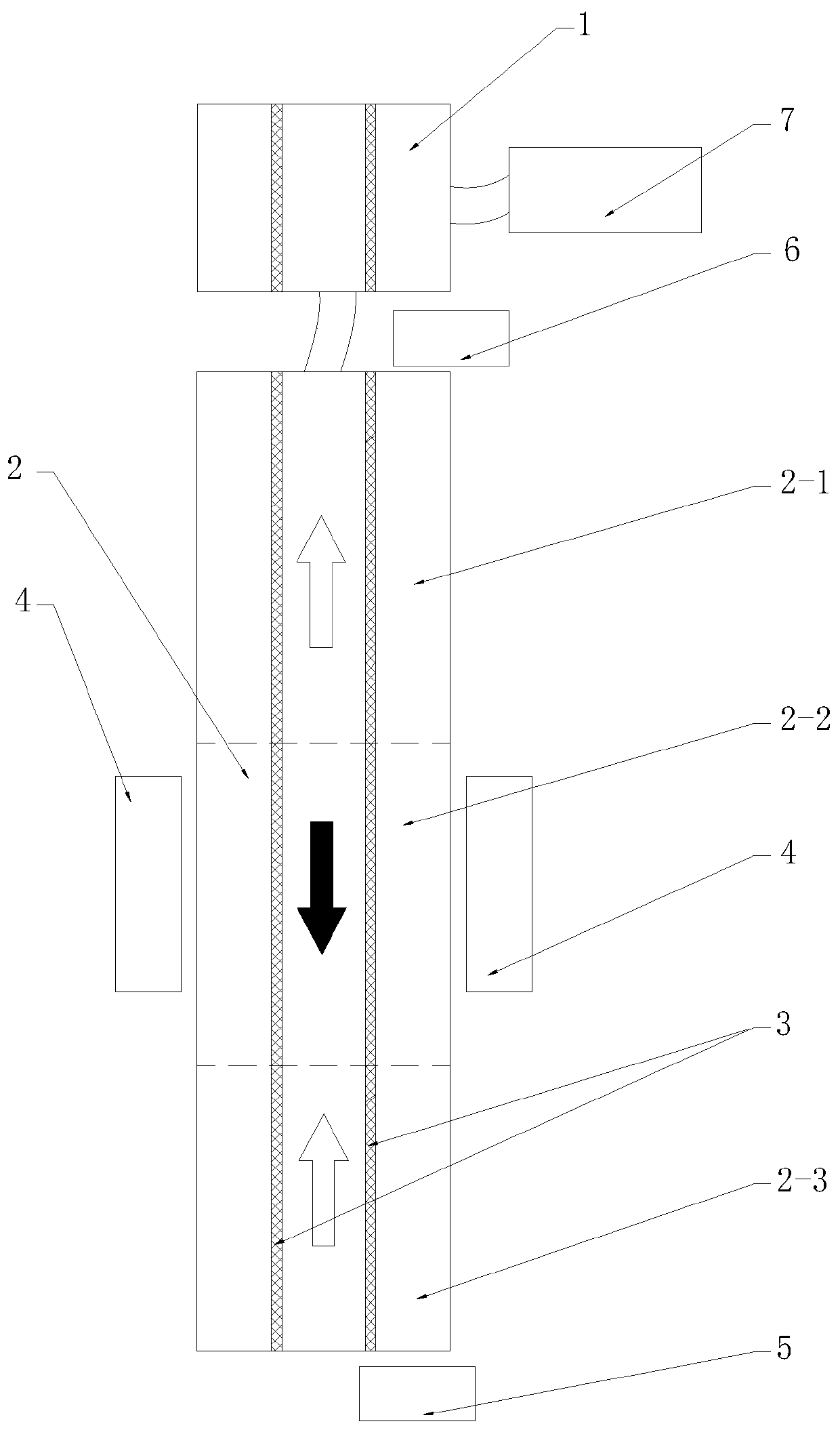

[0024] a kind of like Figure 1 to Figure 2 The strontium carbonate molding and calcination process shown is characterized in that: the raw material is strontium carbonate powder or strontium carbonate slurry, the moisture ratio of the raw material is adjusted to a set value, stirred and mixed to form a brick shape, and calcined in the tunnel kiln 2 , to obtain strontium oxide. Specifically include the following steps:

[0025] S1. The raw materials are transported to the mixing mixer, and the moisture ratio of the raw materials is adjusted to the set value, and mixed evenly;

[0026] The mixed material made by S2 and S1 is transported to the brick press machine to make bricks;

[0027] The strontium carbonate bricks made by S3 and S2 are transported to the warehouse for drying in the shade;

[0028] The strontium carbonate bricks dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com