Shearing pliers shearing waste automatic collecting device

A technology for automatic collection and waste, which is applied in metal processing, dust removal, cleaning methods and utensils, etc. It can solve the problems of flying randomly, not easy to control the flying direction of cut waste, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

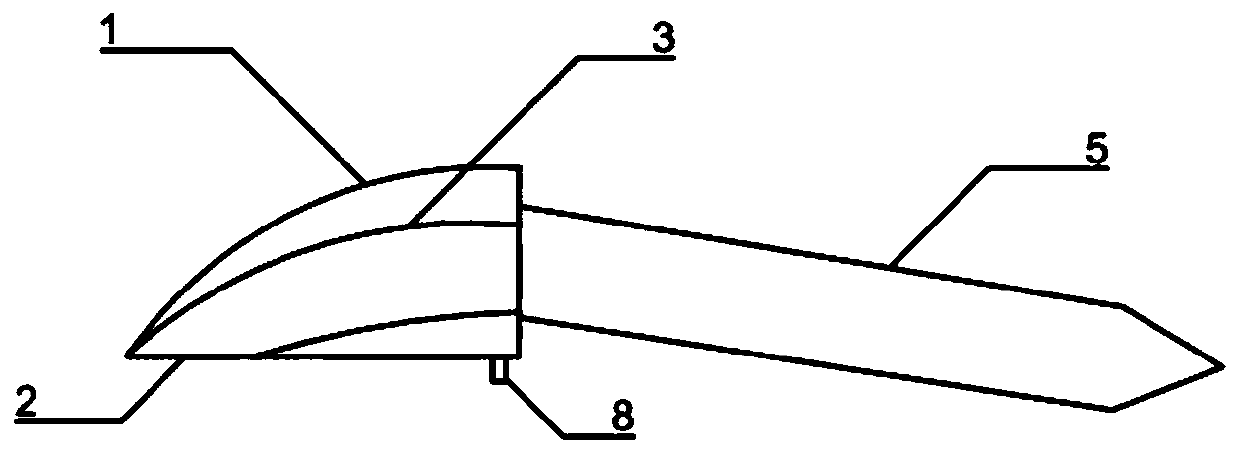

Embodiment 1

[0040]The present invention provides an automatic collection device for scissors cutting waste. Under the action of the shearing force of the scissors, the shearing waste flies in from the entrance 2 of the control member located directly above the jaws of the scissors 11 and passes through the direction. The upper arc-shaped channel 3 inside the control member flies, and after being reflected by the arc wall at the top of the upper arc-shaped channel, it flies out through the direction control member outlet 4 and enters the collection member 5 connected to the direction control member 1; wherein, the direction control member outlet 4 It is located on the right side of the direction control member and is arranged obliquely downward. The outer contour of the entrance of the direction control member matches the outer contour of the jaws 11 when the cutters are closed. The entrance of the direction control member is located at the front section of the bottom of the direction cont...

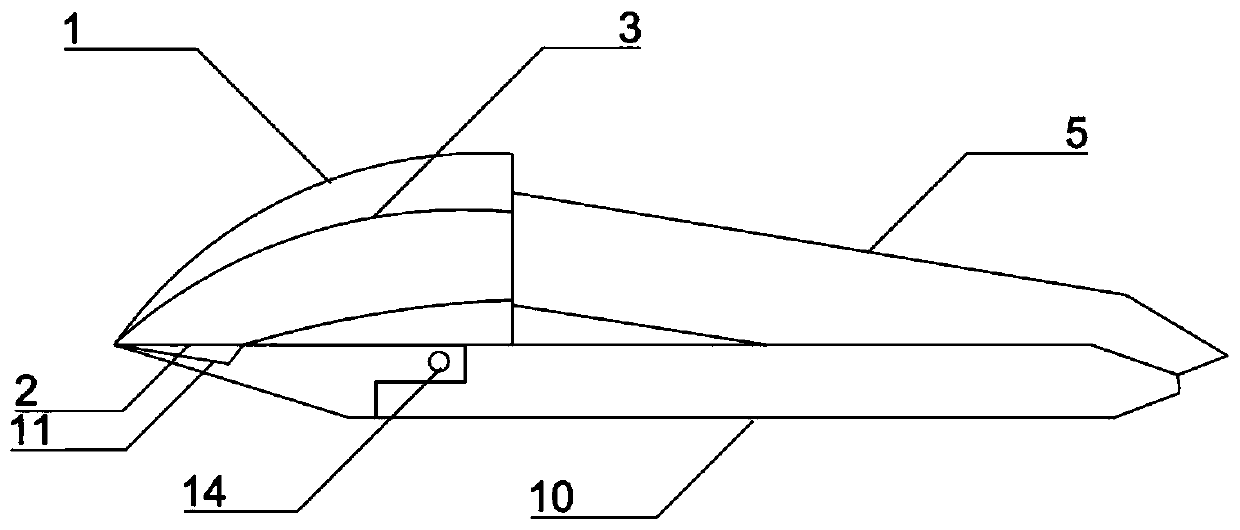

Embodiment 2

[0042] The present invention provides an automatic collection device for scissors cutting waste. Under the action of the shearing force of the scissors, the shearing waste flies in from the entrance 2 of the control member located directly above the jaws of the scissors 11 and passes through the direction. The upper arc-shaped channel 3 inside the control member flies, and after being reflected by the arc wall at the top of the upper arc-shaped channel, it flies out through the direction control member outlet 4 and enters the collection member 5 connected to the direction control member 1; wherein, the direction control member outlet 4 It is located on the right side of the direction control member and is arranged obliquely downward. The outer contour of the entrance of the direction control member matches the outer contour of the jaws 11 when the cutters are closed. The entrance of the direction control member is located at the front section of the bottom of the direction con...

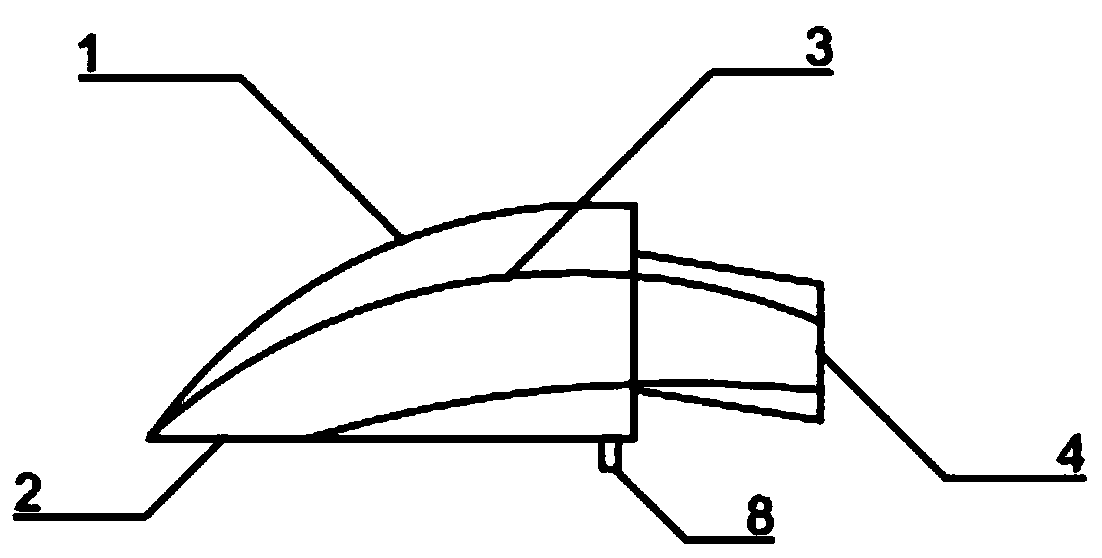

Embodiment 3

[0044] The present invention provides an automatic collection device for cutting waste by scissors. Under the action of the shearing force of the scissors, the waste will fly in from the entrance 2 of the control member located directly above the jaws of the scissors 11 and pass through the direction. The upper arc-shaped channel 3 inside the control member flies, and after being reflected by the arc wall at the top of the upper arc-shaped channel, it flies out through the direction control member outlet 4 and enters the collection member 5 connected to the direction control member 1; wherein, the direction control member outlet 4 It is located on the right side of the direction control member and is arranged obliquely downward. The outer contour of the entrance of the direction control member matches the outer contour of the jaws 11 when the cutters are closed. The entrance of the direction control member is located at the front section of the bottom of the direction control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com