Plywood glue coating device

A technology of gluing device and plywood, applied in the direction of injection device, liquid injection device, etc., can solve the problems of uncontrollable glue amount, glue everywhere, uneven glue application, etc., to achieve accurate glue position and glue application. The effect of uniformity and avoidance of glue waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

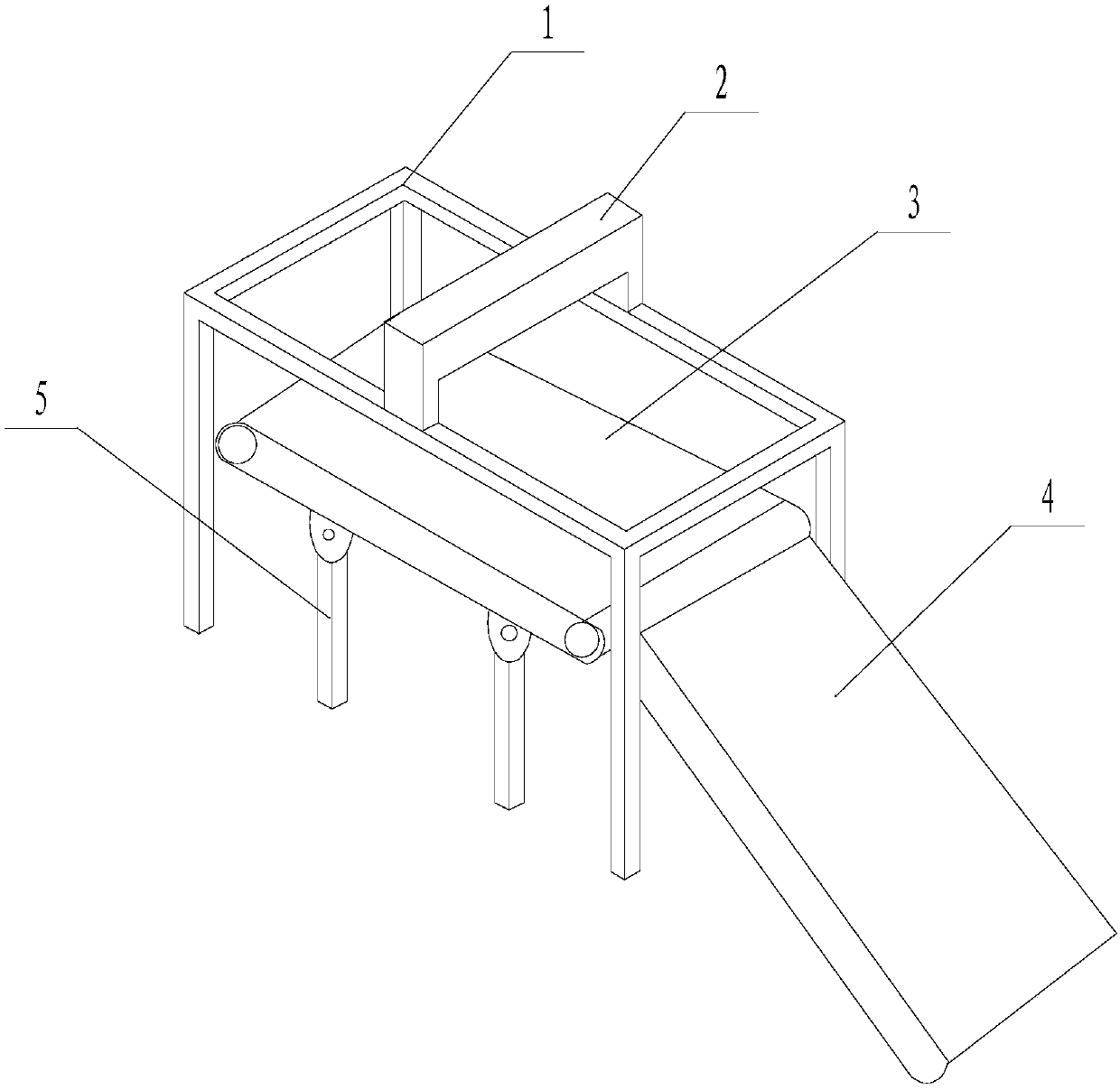

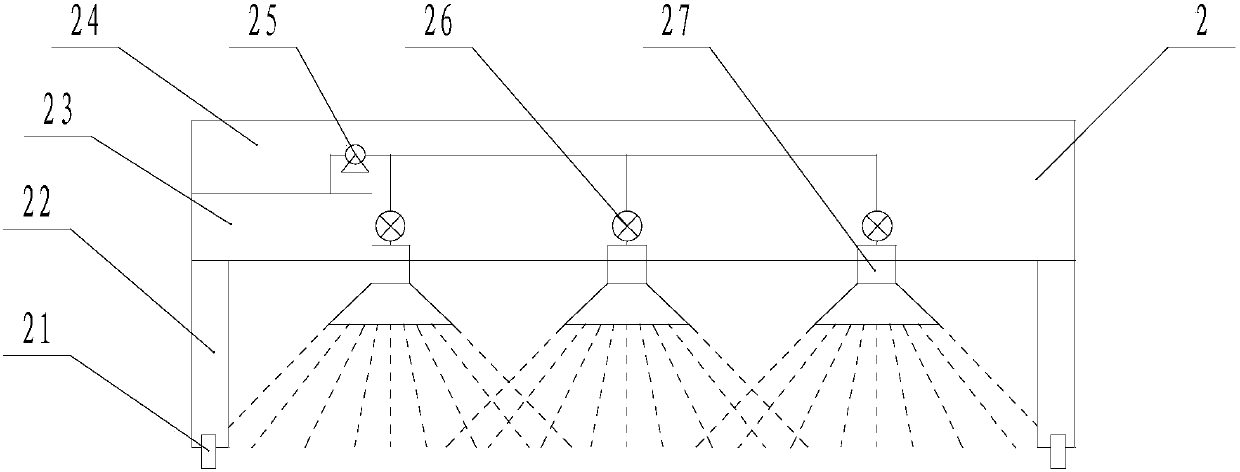

[0017] Described plywood gluing device comprises support 1, gluing machine 2 and supporting table 3, and described gluing machine 2 is made up of gluing support 22 and gluing box 24, and atomizer 27 is arranged on gluing box 24 The atomizer 27 is connected to the glue storage box 23 inside the glue application box 24 through a pipeline, and a water pump 25 is arranged between the atomizer 27 and the glue storage box 23 .

Embodiment 2

[0019] Described plywood gluing device comprises support 1, gluing machine 2 and supporting table 3, and described gluing machine 2 is made up of gluing support 22 and gluing box 24, and atomizer 27 is arranged on gluing box 24 , the atomizer 27 is connected to the glue storage box 23 inside the glue application box 24 through a pipeline, a water pump 25 is arranged between the atomizer 27 and the glue storage box 23, and a flow meter 26 is arranged between the water pump 25 and the atomizer 27 .

Embodiment 3

[0021] Described plywood gluing device comprises support 1, gluing machine 2 and supporting table 3, and described gluing machine 2 is made up of gluing support 22 and gluing box 24, and atomizer 27 is arranged on gluing box 24 , the atomizer 27 is connected to the glue storage box 23 inside the glue application box 24 through a pipeline, a water pump 25 is arranged between the atomizer 27 and the glue storage box 23, and a flow meter 26 is arranged between the water pump 25 and the atomizer 27 . The gluing support 22 of the gluing machine 2 is provided with a slide block 21 , and the support 1 is provided with a chute corresponding to the slide block 21 . The supporting platform 3 is supported by the legs 5 for the conveyor. A slide 4 is provided on the discharge side of the supporting platform 3 .

[0022] The glue storage box 23 of the present invention is placed inside the glue application box 24, and is connected to the atomizer 27 through a pipeline. A water pump 25 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com