A method for comprehensive recovery of silver, tin and iron from quartz vein type tin tailings

A technology for tailings and veins, applied in chemical instruments and methods, solid separation, flotation, etc., can solve problems such as poor sorting effect and large workload, achieve good beneficiation indicators, improve production capacity, and energy consumption. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

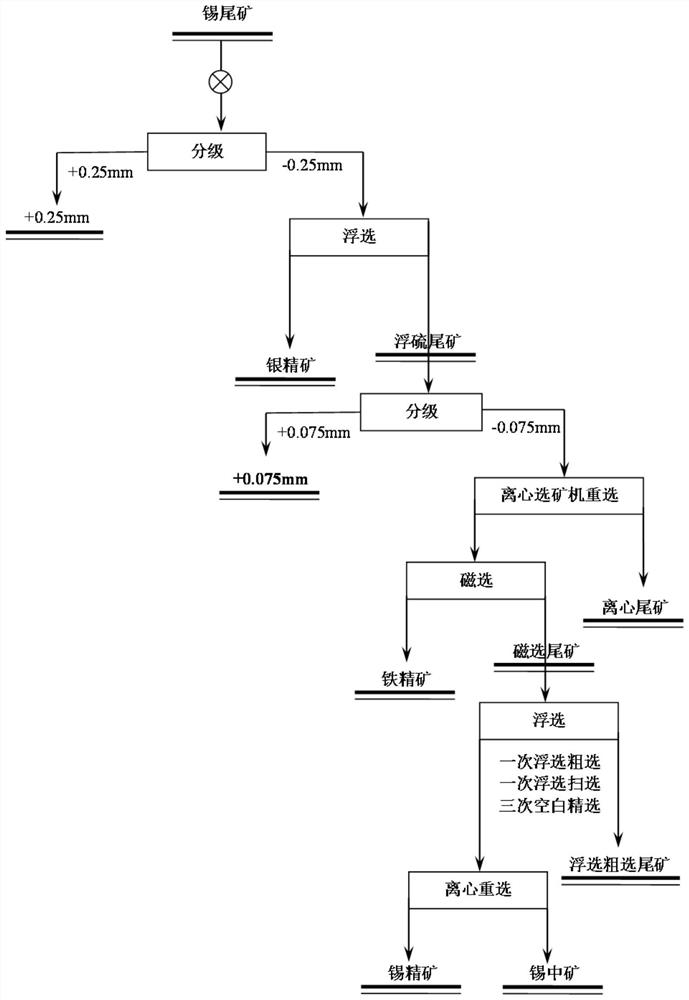

[0052] The present embodiment provides a method for comprehensively recovering silver, tin and iron from quartz vein type tin tailings, such as figure 1 , the process is as follows.

[0053]A certain tin tailings has a tin grade of 0.34%, an iron grade of 12.50% and a silver grade of 25.30g / t, and cassiterite is mainly composed of fine particles. The ore samples are classified into two grades of +0.25mm and -0.25mm after stirring and pulping. Among them, the yield rate of +0.25mm particle size is 16.09%, the tin grade is 0.17%, and the tin recovery rate is 7.97%. -0.25mm particle size, add water to adjust the slurry to a concentration of 30%. According to each ton of ore, add 80 grams of 1,3-dimethylbutyl xanthate sodium and 40 grams of methyl pentanol for roughing. Add 40 grams of 1,3-dimethylbutyl xanthate sodium and 20 grams of methyl amyl alcohol to the tailings for scavenging; the rough concentrate and sweep concentrate are combined into sulfur rough concentrate, and th...

Embodiment 2

[0055] This embodiment provides a method for comprehensively recovering silver, tin and iron from quartz vein type tin tailings, and the process is as follows.

[0056] The tin grade of a tin tailings is 0.40%, the iron grade is 15.42% and the silver grade is 22.33g / t. The ore samples are classified into two grades of +0.25mm and -0.25mm after stirring and pulping. -0.25mm particle size, add water to adjust the pulp to a concentration of 29%. According to each ton of ore, add 100 grams of 1,3-dimethylbutyl xanthate sodium and 30 grams of methyl amyl alcohol for roughing, roughing Add 50 grams of 1,3-dimethylbutyl xanthate sodium and 15 grams of methyl amyl alcohol to the tailings for scavenging; the rough concentrate and the sweep concentrate are combined into sulfur rough concentrate, and the silver recovery rate is 89.35% . Sulfur dressing tailings are classified into two grades of +0.075mm and -0.075mm, and -0.075mm is re-selected by centrifugal concentrator to obtain cen...

Embodiment 3

[0058] This embodiment provides a method for comprehensively recovering silver, tin and iron from quartz vein type tin tailings, and the process is as follows.

[0059] The tin grade of a tin tailings is 0.49%, the iron grade is 11.39% and the silver grade is 35.23g / t. The ore samples are classified into two grades of +0.25mm and -0.25mm after stirring and pulping. -0.25mm particle size, add water to adjust the pulp to a concentration of 30%, and add 90 grams of 1,3-dimethyl butyl xanthate potassium and 30 grams of methyl pentanol in turn for roughing, based on the calculation of each ton of ore. Add 45 grams of 1,3-dimethylbutyl xanthate potassium and 15 grams of methyl amyl alcohol to the tailings for scavenging; the rough concentrate and sweep concentrate are combined into sulfur rough concentrate, and the silver recovery rate is 93.25% . Sulfur dressing tailings are classified into two grades of +0.075mm and -0.075mm, and -0.075mm is re-selected by centrifugal concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com