A high-efficiency cone crusher

A cone crusher, high-efficiency technology, applied in the field of mining and quarrying, can solve the problems of reduced work efficiency, slag splashing, personnel safety threats, etc., and achieve the effects of safe and convenient use, guaranteed crushing effect, and scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

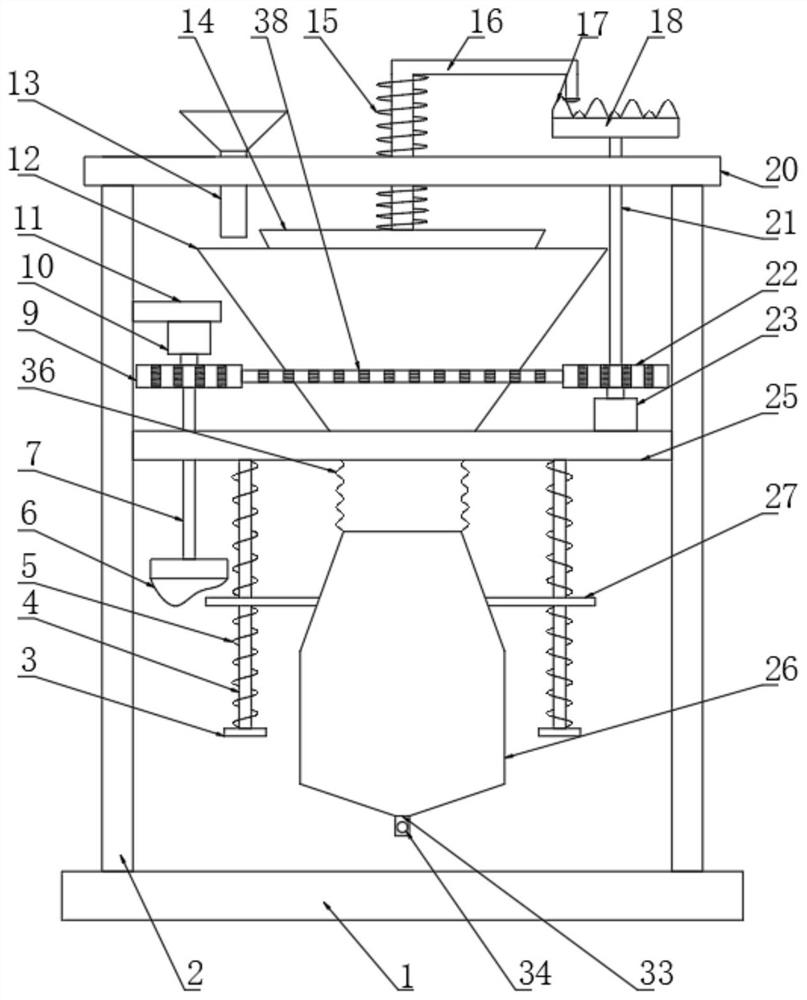

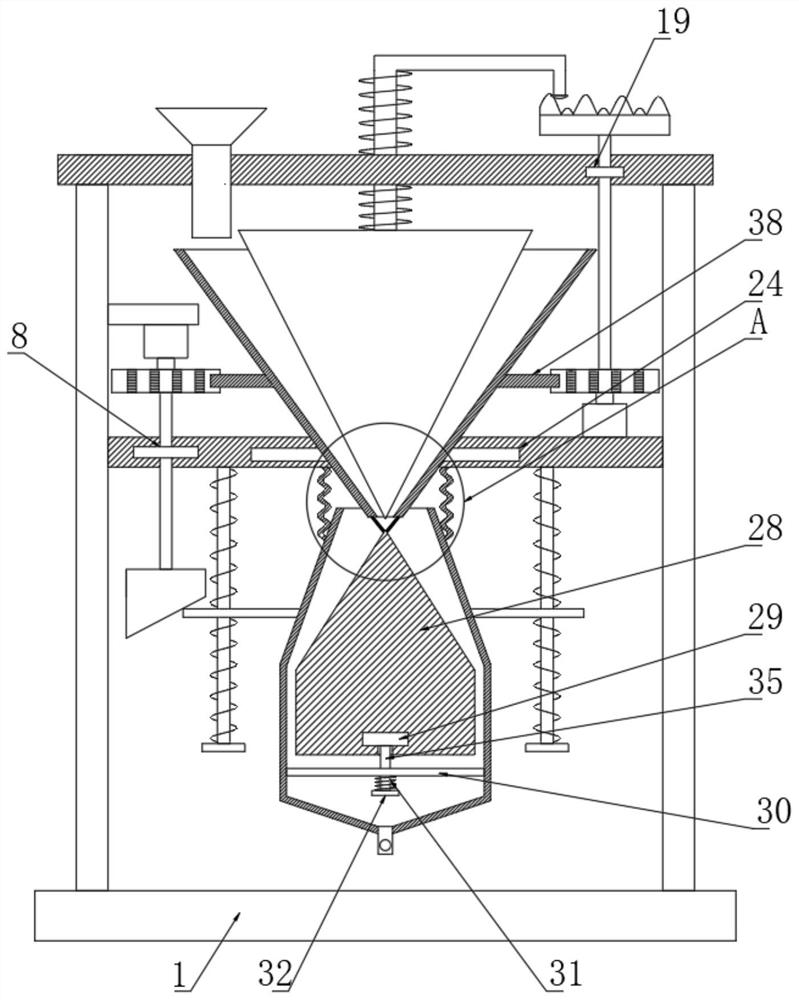

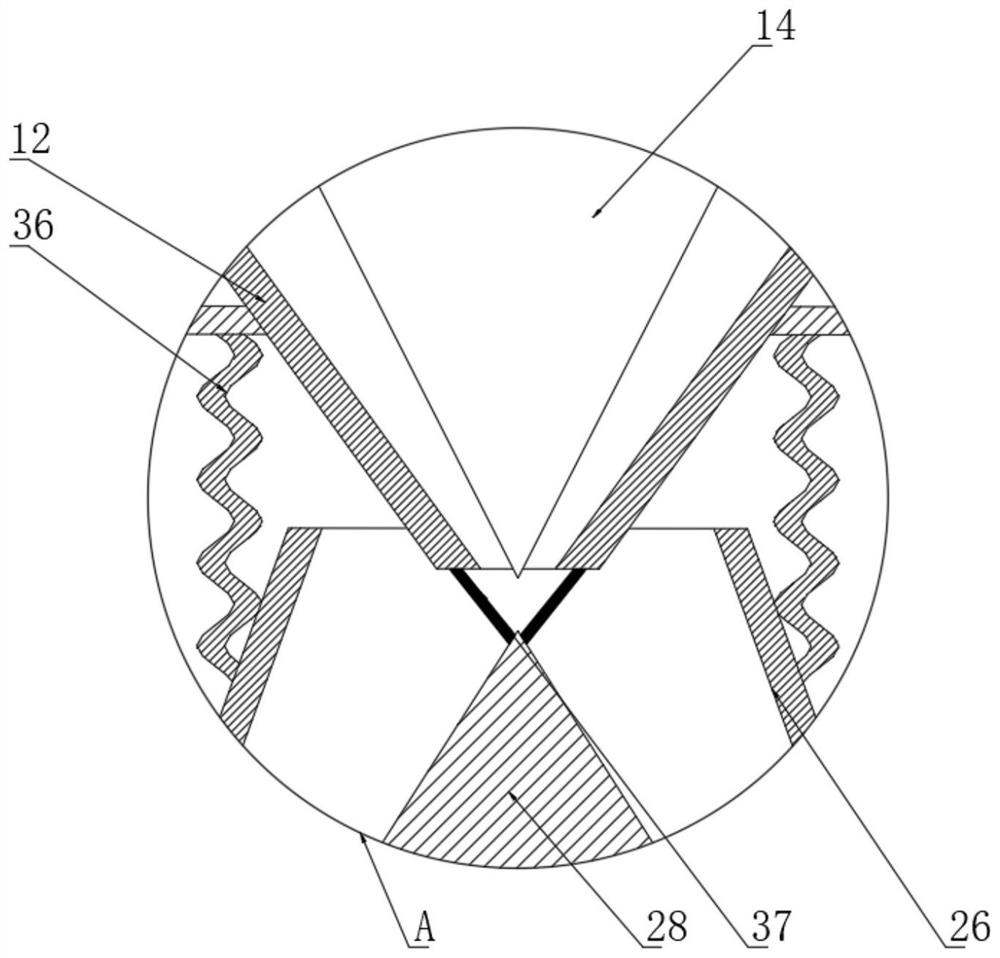

[0026] Example: such as Figure 1-4 As shown, the present invention provides a technical solution, a high-efficiency cone crusher, including a bottom plate 1, both sides of the top of the bottom plate 1 are fixedly connected with support rods 2, and the top surfaces of the two support rods 2 are fixedly connected with the same horizontal plate 20, A support plate 25 is installed directly below the horizontal plate 20 through two poles 2. The top of the support plate 25 is rotatably connected to the conical cylinder 12, and the bottom of the conical cylinder 12 is fixedly connected to the third rotating block 24. The third rotating block 24 Embedded in the support plate 25 and connected to it in rotation, the middle part of the conical cylinder 12 above the support plate 25 is clamped and fixed with the main gear 38;

[0027] The two ends of the main gear 38 are engaged with the first gear 9 and the second gear 22 respectively, the top surface of the first gear 9 is fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com