A fast hydrothermal preparation method of tetragonal copper bismuthate photocatalyst and its application in degrading methylene blue

A photocatalyst, methylene blue technology, applied in the field of photocatalysis, can solve the problems of secondary pollution, difficult to achieve treatment effect, inability to degrade organic dye molecules, etc., to achieve cost reduction, good ability to degrade organic pollutants, and short preparation time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

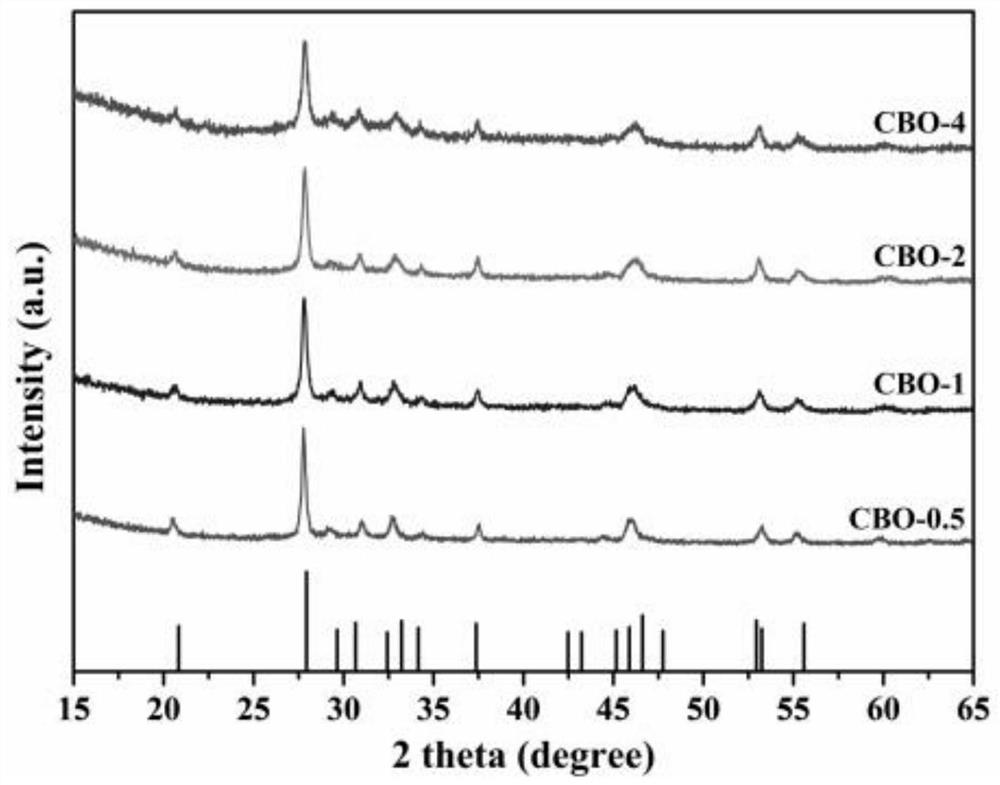

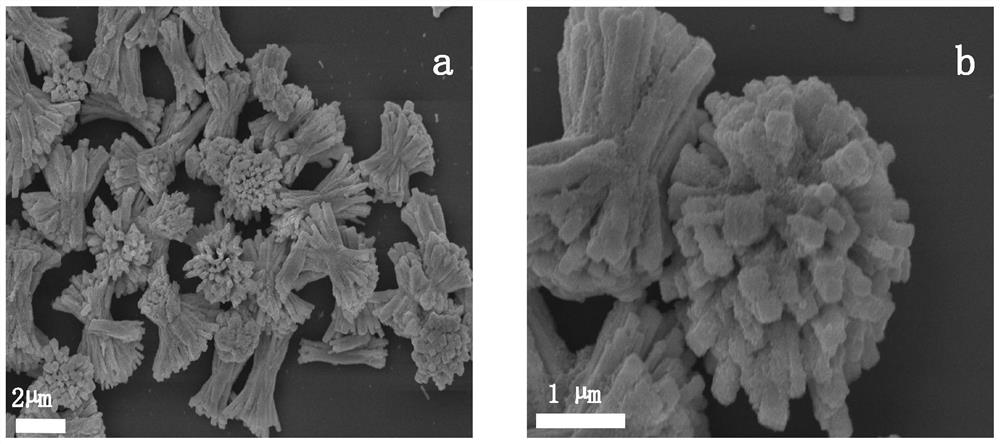

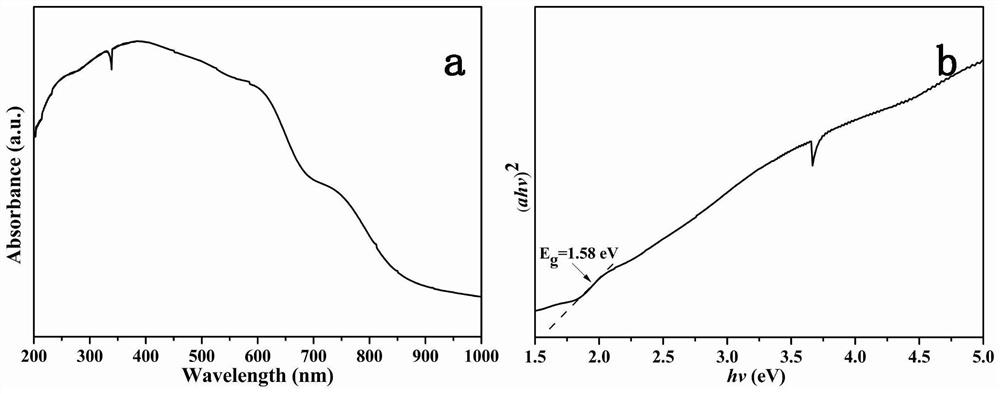

[0033] Example 1: Method for preparing tetragonal copper bismuthate photocatalyst by rapid hydrothermal method

[0034] It includes the following steps: respectively preparing an acetic acid solution of bismuth nitrate pentahydrate and an ethanol solution of copper nitrate trihydrate: dissolving 2mmol of bismuth nitrate pentahydrate in 5mL of acetic acid, dissolving 1mmol of copper nitrate trihydrate in 25mL of ethanol solution, and then dissolving pentahydrate nitric acid The acetic acid solution of bismuth was mixed with the ethanol solution of copper nitrate trihydrate, magnetically stirred for 5 minutes, and then ultrasonically dispersed for 5 minutes to obtain a uniform mixture. Then, under magnetic stirring, 15 mL of 6 mol / L sodium hydroxide solution was slowly added dropwise to the pH of the solution. =14, the dropping rate of sodium hydroxide was 1 mL / min, then the mixture was transferred to a 100 mL autoclave, heated to 120° C. and kept for 1 h. After the heating was ...

Embodiment 2

[0037] Referring to Example 1, the difference is that the hydrothermal reaction time is 0.5h.

Embodiment 3

[0039] Referring to Example 1, the difference is that the hydrothermal reaction time is 2h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com