Method for installing booster stations for wind power and photovoltaic power generation systems

A technology of photovoltaic power generation system and installation method, which is applied to switchgear, electrical components, multi-purpose hand tools, etc., can solve the problems of non-standard installation methods and standards, different standards, and increased difficulty for construction enterprises, so as to reduce the installation of GIS The effect of accumulating errors, ensuring rapidity, improving installation accuracy and equipment safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

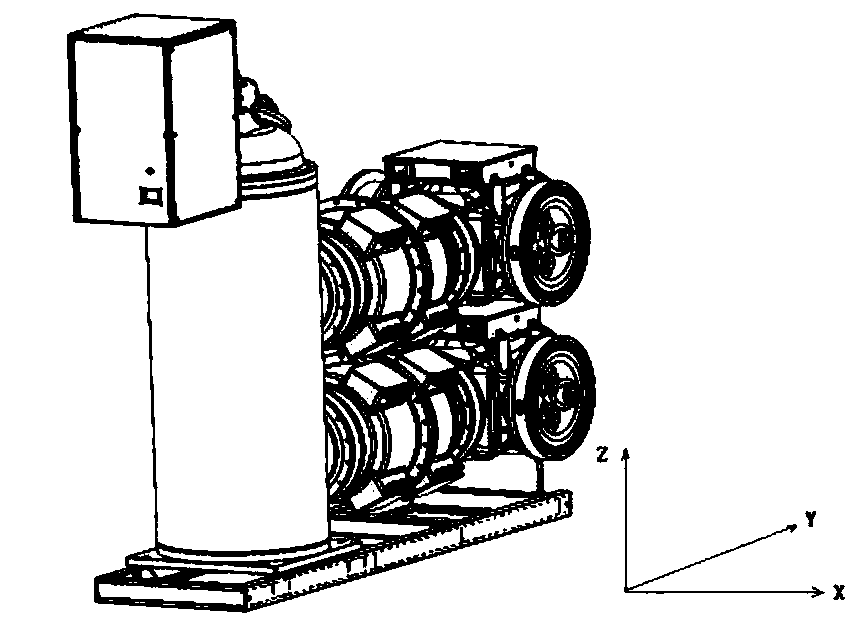

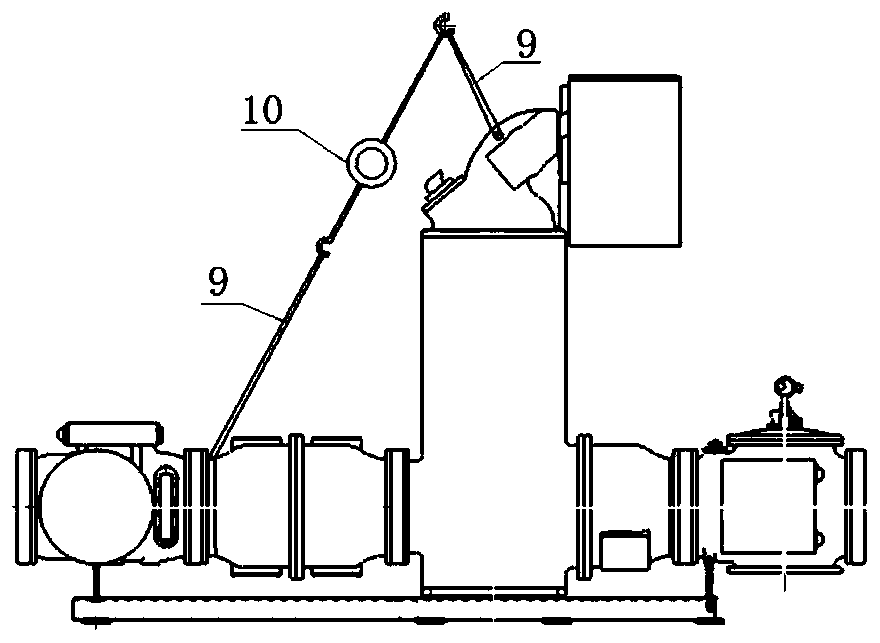

[0040] See Figure 1-Figure 13 , a method for installing a booster station of a wind power and photovoltaic power generation system, comprising the following method steps:

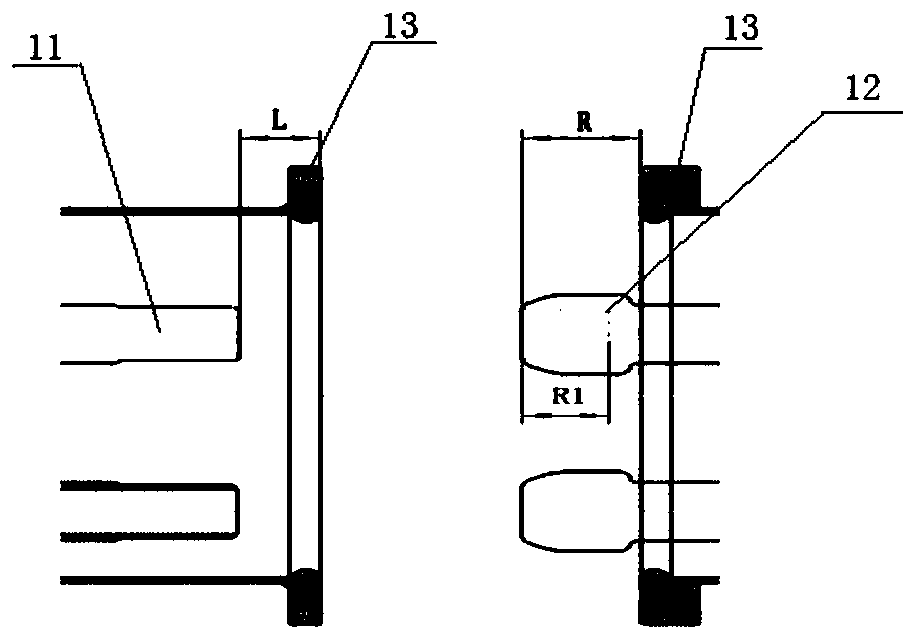

[0041] 1) Install the GIS foundation first. The ground bearing capacity of the GIS foundation is not less than 10t. The adjustment method of the foundation height is:

[0042] a) Find out the highest point of the metal embedded parts according to the actual measurement of the base height of each interval, mark the height of this point as "L", adjust the installation base height of the first interval with the gasket, and mark the height of this point as "L" after adjustment '", the adjustment range of the base height of the first interval is L'=L+(5~10)mm;

[0043] b) Based on the actual height of the highest point of the metal embedded part of the first interval foundation a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com