A kind of high-altitude grid installation method

An installation method and grid technology, which are applied to truss structures, joists, girders, etc., can solve the problems of low overall accuracy, complicated operation, and large engineering volume of high-altitude installation of grids. Stable installation and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] Example description

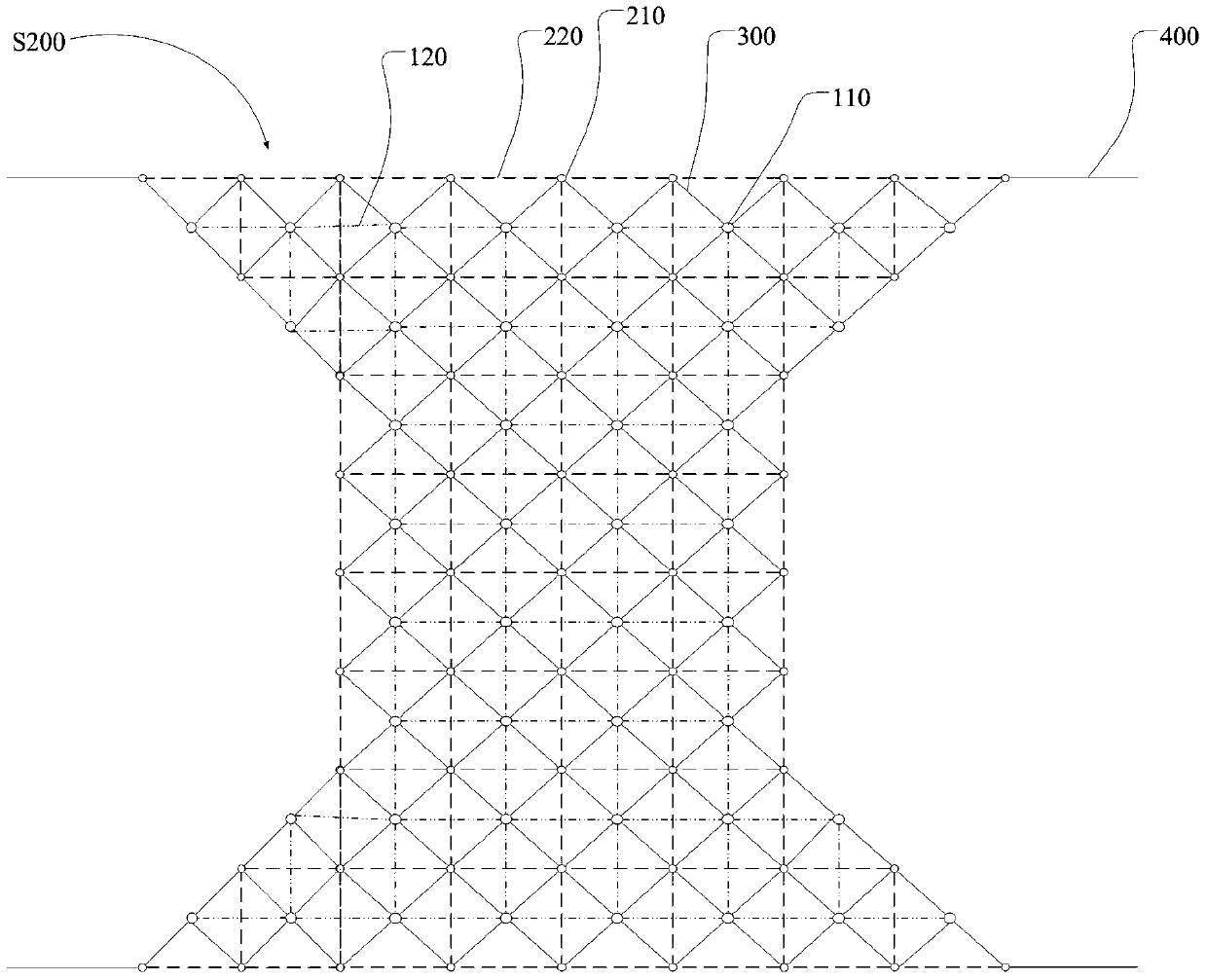

[0047] The high-altitude network frame installation method of the present application, by installing the initial starting span on the supporting base, using the supporting base and the two sides of the starting span as the basis for widening, four triangular edge grids are formed, and then the two opposite triangular The middle part of the edge grid is widened to form a new starting span, and then the installation is repeated on the basis of the new starting card until the installation of the high-altitude grid is completed, which realizes the safe and efficient installation of the high-altitude grid and avoids the installation of the conventional high-altitude grid Problems with complex operation and large engineering volume.

specific Embodiment

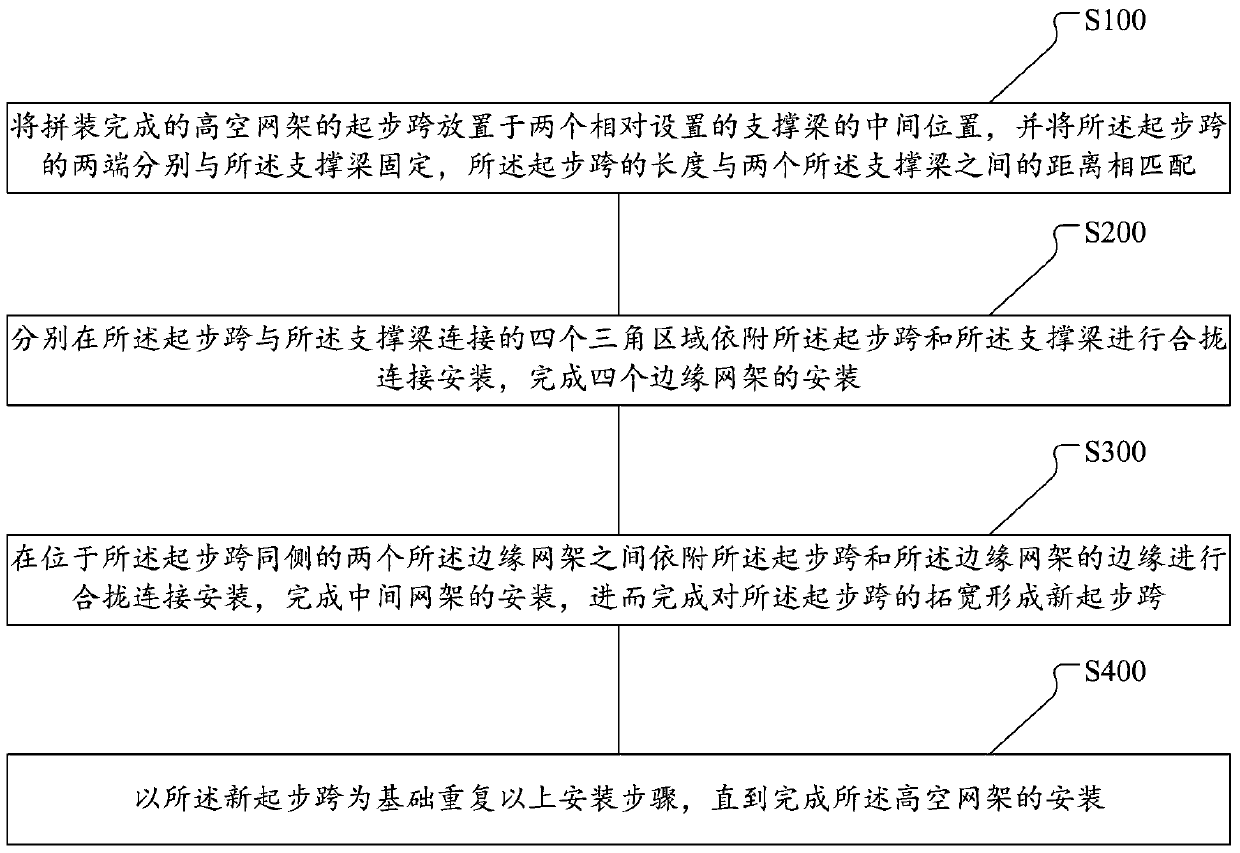

[0048] See attached figure 1 , is a schematic flow chart of the installation method of the high-altitude network frame of the present invention. The installation method of the high-altitude grid frame of the present invention comprises:

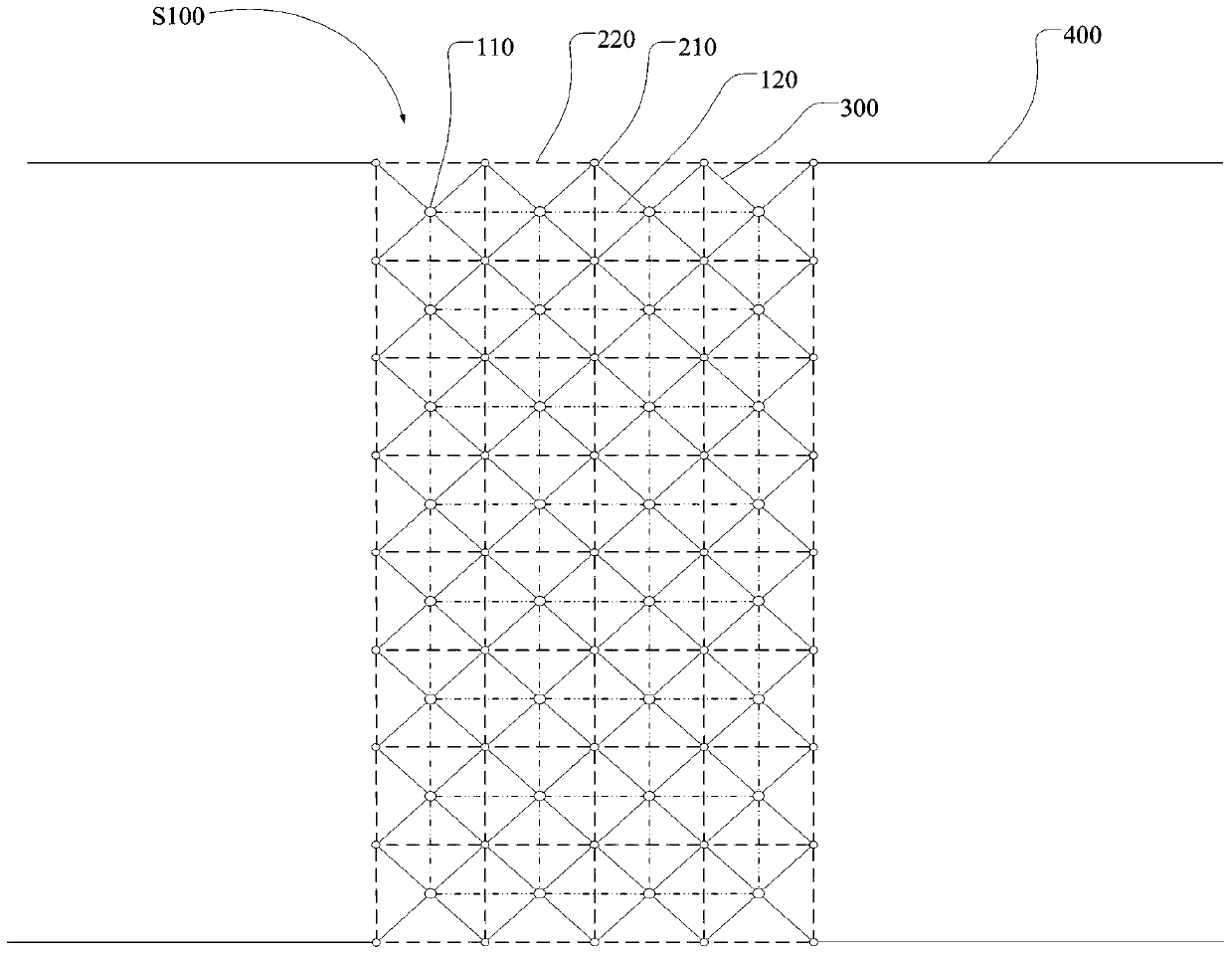

[0049] S100: Place the starting span of the assembled high-altitude network frame in the middle of four oppositely arranged supporting bases 400, and fix the two ends of the starting span to the supporting bases 400 respectively, the length of the starting span match the distance between the two support bases 400;

[0050] S200: Attach the starting span and the supporting base 400 to connect and install the four triangular areas where the starting span and the supporting base 400 are connected, and complete the installation of the four edge grids;

[0051] S300: Between the two edge grids located on the same side of the starting span, close and connect and install the edges of the starting span and the edge grids to complete the installatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com