Method for predicting metal cutting tool nose dead zone morphology through considering metal slippage

A metal cutting, metal slipping technology used in special data processing applications, instruments, electrical digital data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

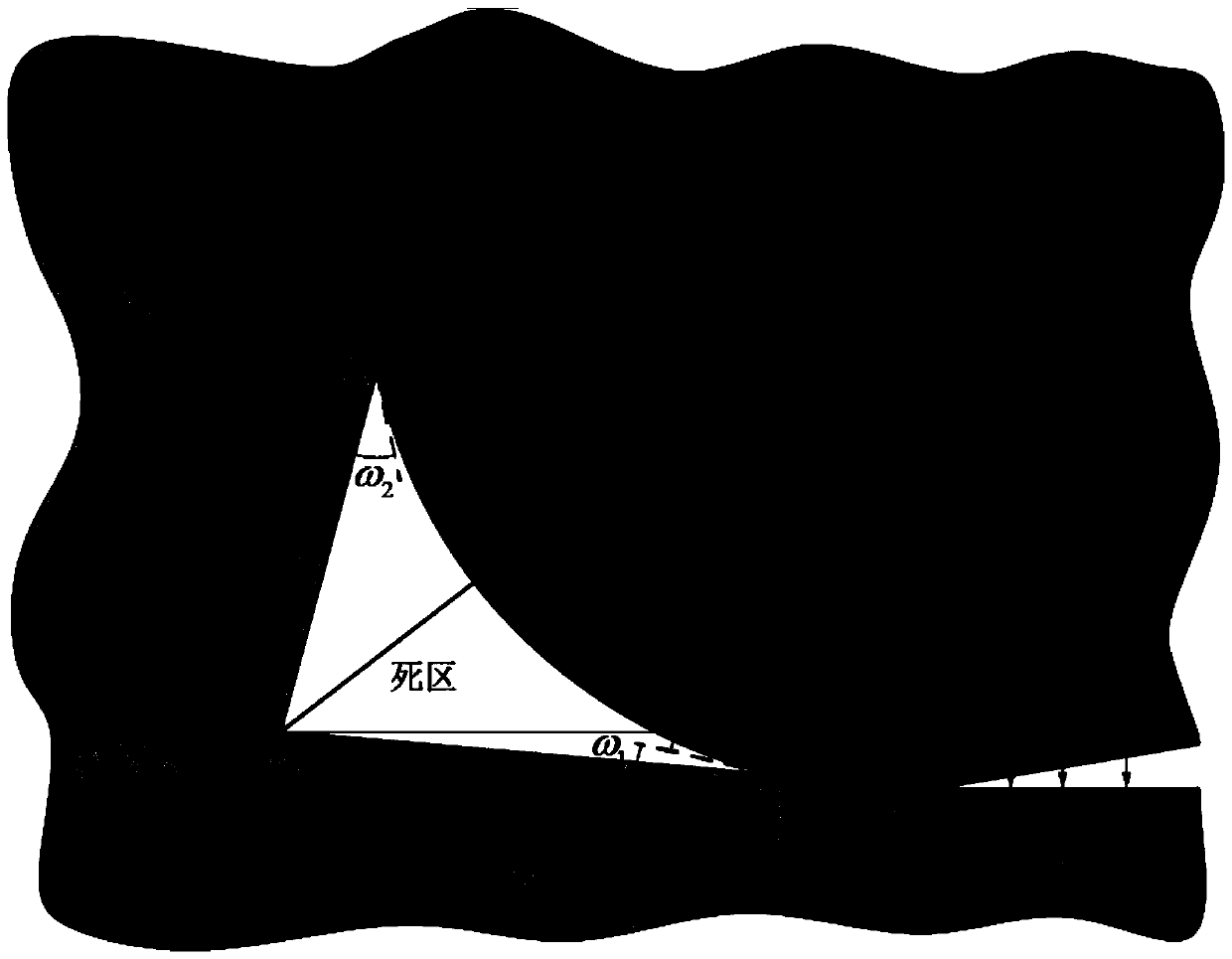

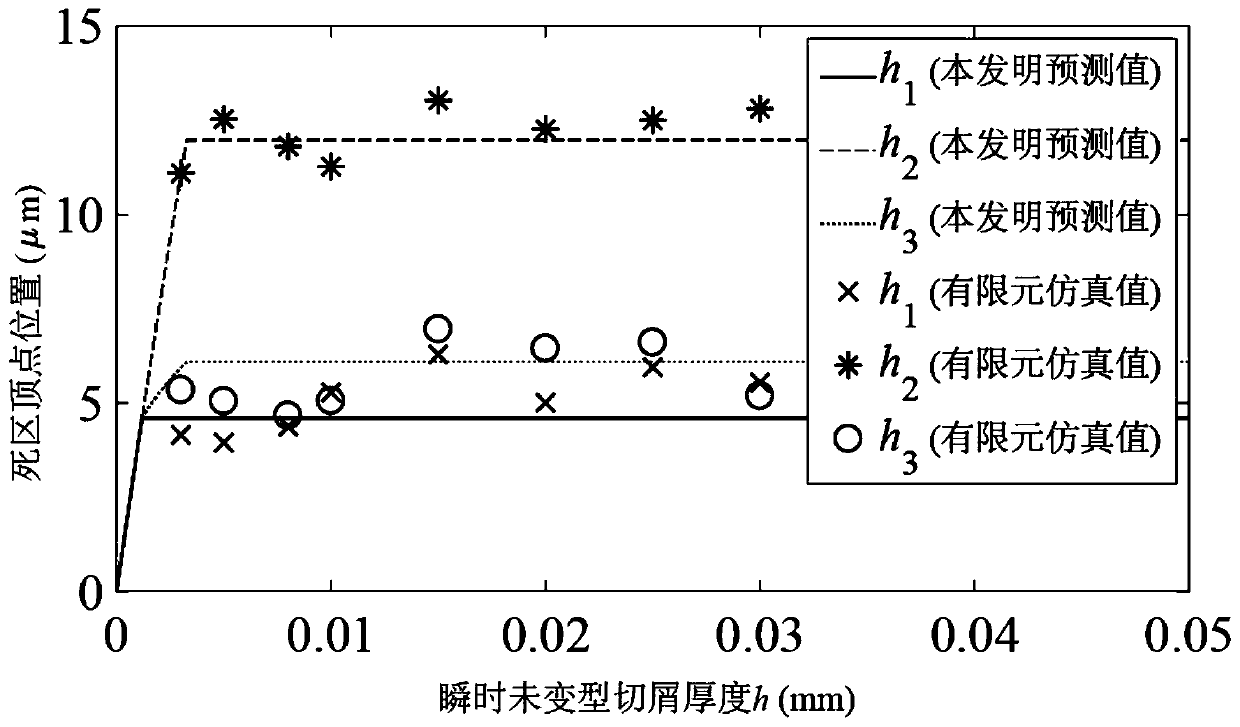

[0097] The finite element simulation is set to a two-dimensional right-angle cutting simulation model of aluminum alloy 7050-T7451, and the tool is set to the radius r of the blunt circle of the tool tip e = 0.02 mm, rake angle α = 5 degrees. The friction coefficient between the blunt circle of the tool nose and the rake face is determined by the cutting data published in the right-angle cutting parameter library. The modeling method of the model refers to the finite element modeling method disclosed in the literature "X.Jin, Y.Altintas, Prediction of micro-milling forces with finite element method, Journal of Materials Processing Technology 212(3)(2012)542-552." .

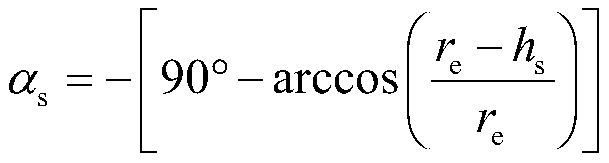

[0098] Step 1. Set the distance from an unknown point on the blunt circle of the knife tip to the lowest point of the blunt circle as h s . The rake angle α at the unknown point on the blunt circle of the tool tip s Expressed as:

[0099]

[0100] The shear angle φ s Expressed as:

[0101] φ s =45°-(β ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com