Unfolding method of double-curvature plate

A technology of hyperbolic and curved plates, applied in the field of expansion of hyperbolic plates, can solve the problems of shrinkage of hull plate and difference in expansion area, and achieve the effects of improving efficiency, uniform deformation and good precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

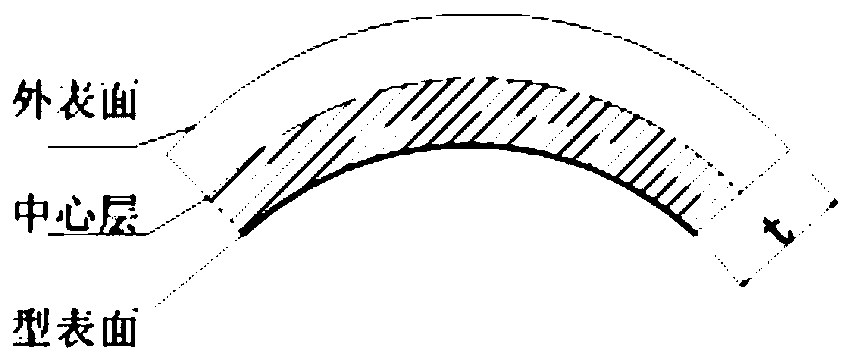

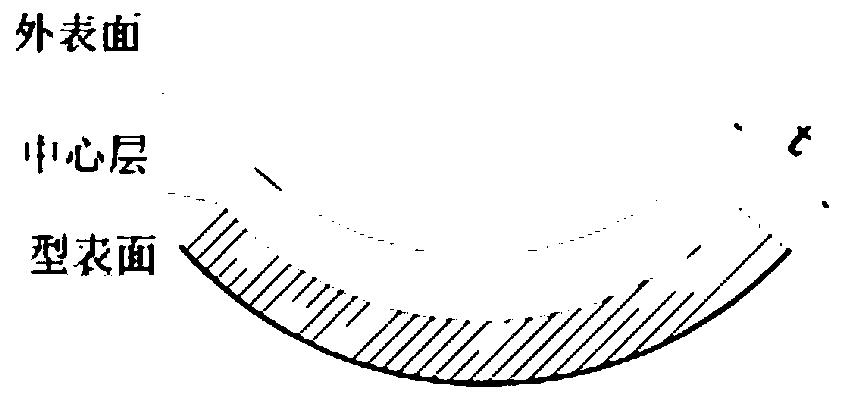

[0035] An unfolding method for a double-curvature plate. On the basis of considering the thickness of the plate and the forming method of the curved plate, a finite element discretization method is used to discretize the curved plate, and then splicing is carried out after approximately unfolding. The specific implementation of the unfolding method is as follows:

[0036] Such as figure 1 Shown is a flow chart of a method for unfolding a hyperbolic slab. The specific expansion steps are as follows

[0037] 1. Surface fitting: through a series of three-dimensional space points of a given hyperbolic plate, it is fitted into a curved B-spline surface, which can realize the interpolation of any point on the surface and the calculation of the curvature. The B-spline surface S(u,v) of order k×l can be expressed as:

[0038]

[0039] In the formula,

[0040] {d i,j}(i=0,1,...,m; j=0,1,...,n) is an array of control vertices in a given space (m+1)(n+1), N i,k (u)(i=0,1,...,m) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com