Testing method for timeliness of battery grid

A detection method and time-sensitive technology, applied in the direction of measurement device, strength characteristics, and the use of stable tension/pressure to test the strength of materials, etc., to avoid deformation and cards, improve the pass rate of slitting, and the detection method is simple and accurate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0014] This embodiment provides a method for detecting the timeliness of a battery grid, including the following steps:

[0015] A. Randomly select 10 large grids, and randomly cut out a small grid from the 10 large grids respectively, to obtain 10 small grids;

[0016] B. Measure the pre-detection length of one of the diagonals of the 10 small grids respectively, and obtain a total of 10 pre-detection lengths (in mm);

[0017] 1 2 3 4 5 6 7 8 9 10 79.34 79.26 79.32 79.3 79.22 79.28 79.32 79.38 79.34 79.36

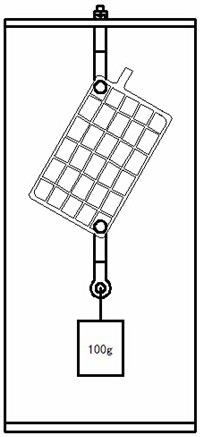

[0018] C. If figure 1 , hang 10 small grids respectively, and keep the diagonal line measured above vertically, and then hang a weight of 100g at the bottom of the diagonal line;

[0019] D. After hanging for 60s, remove the small grid, and measure the post-detection lengths of the above-mentioned diagonals of the 10 small grids again, and obtain a total of 10 post-test lengths (in mm);

[0020] 1 2 3 4 5 6 7 8 9 10 ...

Embodiment approach 2

[0023] This embodiment provides a method for detecting the timeliness of a battery grid, including the following steps:

[0024] Steps A-D are exactly the same as those in Embodiment 1, and will not be repeated here.

[0025] E. Calculated by the above 10 pre-test lengths and 10 post-test lengths, the average value of the extreme difference is 0.49mm, which is less than the reference value of 0.5mm, indicating that the deformation of the grid is small, and the aging strength of the grid meets the process requirements .

Embodiment approach 3

[0027] This embodiment provides a method for detecting the timeliness of a battery grid, including the following steps:

[0028] Steps A-D are exactly the same as those in Embodiment 1, and will not be repeated here.

[0029] E. Calculated by the above 10 pre-test lengths and 10 post-test lengths, the average value of the extreme difference is 0.45mm, which is less than the reference value of 0.5mm, indicating that the deformation of the grid is small, and the aging strength of the grid meets the process requirements .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com