Electric scraper random cable core breakage detection device and detection method

A technology of electric scraper and detection device, applied in the direction of measuring device, measuring electricity, measuring electric variables, etc., can solve problems such as delay in production, difficult to accurately judge cables, and equipment damage, etc., and achieve the effect of simple and accurate detection method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

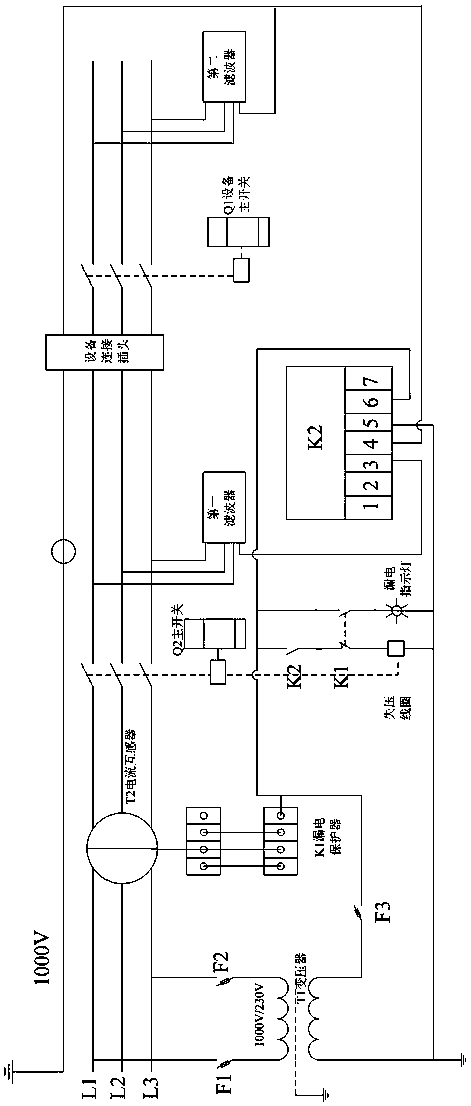

[0018] Such as figure 1 As shown, the detection device for the broken core of the random cable of the electric scraper in this embodiment includes a power distribution cabinet, an equipment control cabinet, and an electric scraper electrical appliance that are sequentially connected to the main circuit of the power supply. There is a zero-sequence current transformer connected to the main power supply circuit, the zero-sequence current transformer is connected to a leakage protector, the main power supply circuit is provided with a main switch, and the power distribution cabinet is provided with There is a first filter, and the second filter of the ground wire detector is installed in the equipment control cabinet, and the third filter is connected in parallel with the first filter or the second filter .

[0019] A method for detecting broken cores of cables using the detection device for random broken cores of the above-mentioned electric scraper, the method comprising:

[...

Embodiment 2

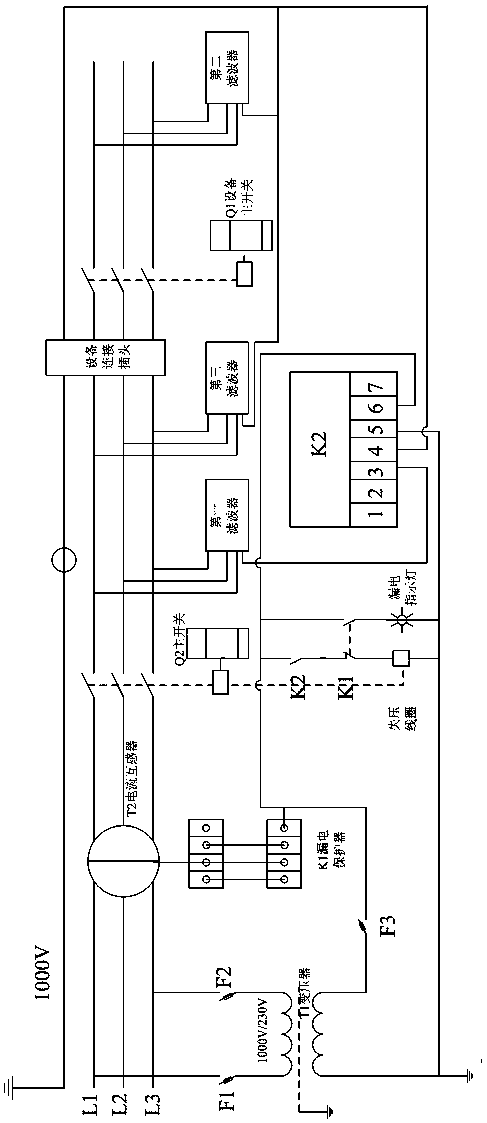

[0022] Such as figure 2 As shown, the detection device for the broken core of the random cable of the electric scraper in this embodiment includes a power distribution cabinet, an equipment control cabinet, and an electric scraper electrical appliance that are sequentially connected to the main circuit of the power supply. There is a zero-sequence current transformer connected to the main power supply circuit, the zero-sequence current transformer is connected to a leakage protector, the main power supply circuit is provided with a main switch, and the power distribution cabinet is provided with There is a first filter, and a second filter of a ground wire detector connected to the power supply circuit is arranged in the equipment control cabinet.

[0023] A method for detecting broken cores of cables using the detection device for random broken cores of the above-mentioned electric scraper, the method comprising:

[0024] After the disconnection protection works, when it is...

Embodiment 3

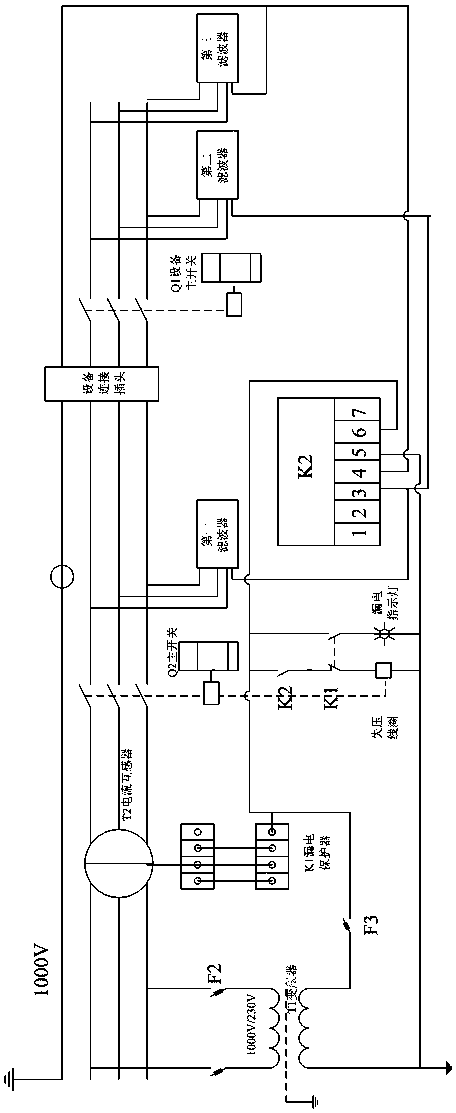

[0026] Such as image 3 As shown, the detection device for the broken core of the random cable of the electric scraper in this embodiment includes a power distribution cabinet, an equipment control cabinet, and an electric scraper electrical appliance that are sequentially connected to the main circuit of the power supply. There is a zero-sequence current transformer connected to the main power supply circuit, the zero-sequence current transformer is connected to a leakage protector, the main power supply circuit is provided with a main switch, and the power distribution cabinet is provided with There is a first filter, and a second filter of a ground wire detector connected to the power supply circuit is arranged in the equipment control cabinet.

[0027] A method for detecting broken cores of cables using the detection device for random broken cores of the above-mentioned electric scraper, the method comprising:

[0028] After the disconnection protection works, when it is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com