Supporting and automatic adjusting device for check tools and control method of supporting and automatic adjusting device

An automatic adjustment and control method technology, applied in the direction of measuring devices, mechanical devices, mechanical measuring devices, etc., can solve the problems of complicated adjustment work, low precision, and affecting the accuracy of adjustment, so as to optimize the test operation steps and improve the work efficiency. Efficiency, the effect of avoiding disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

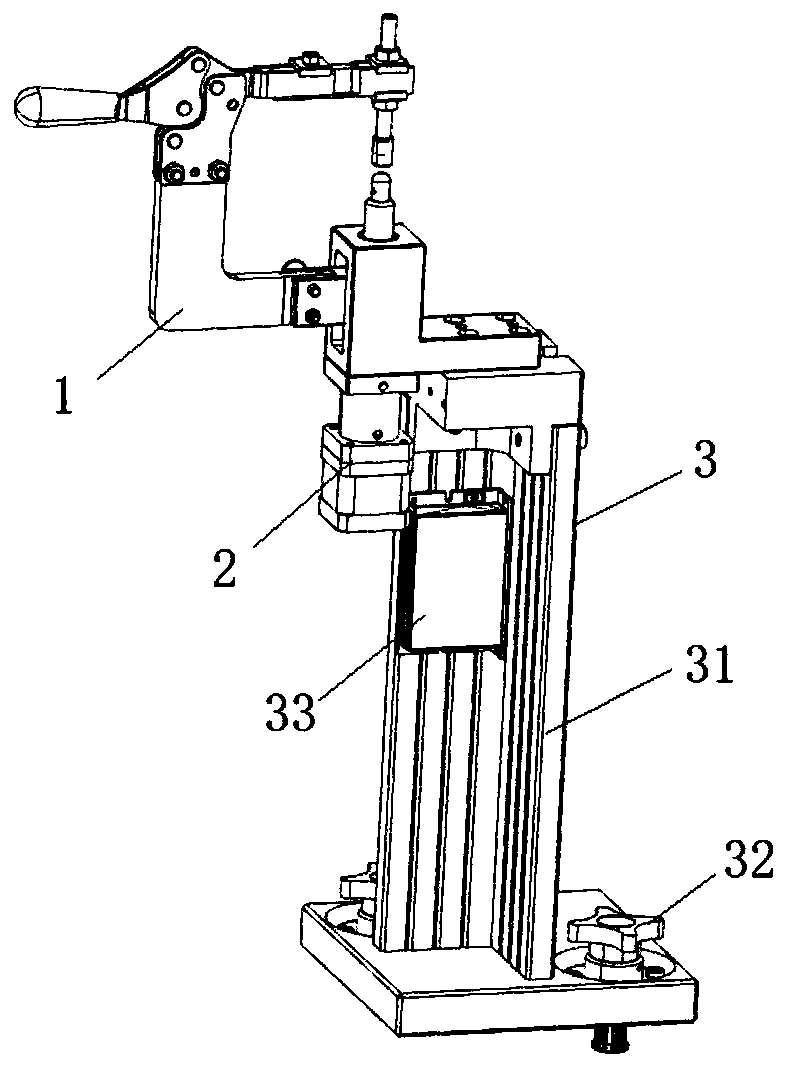

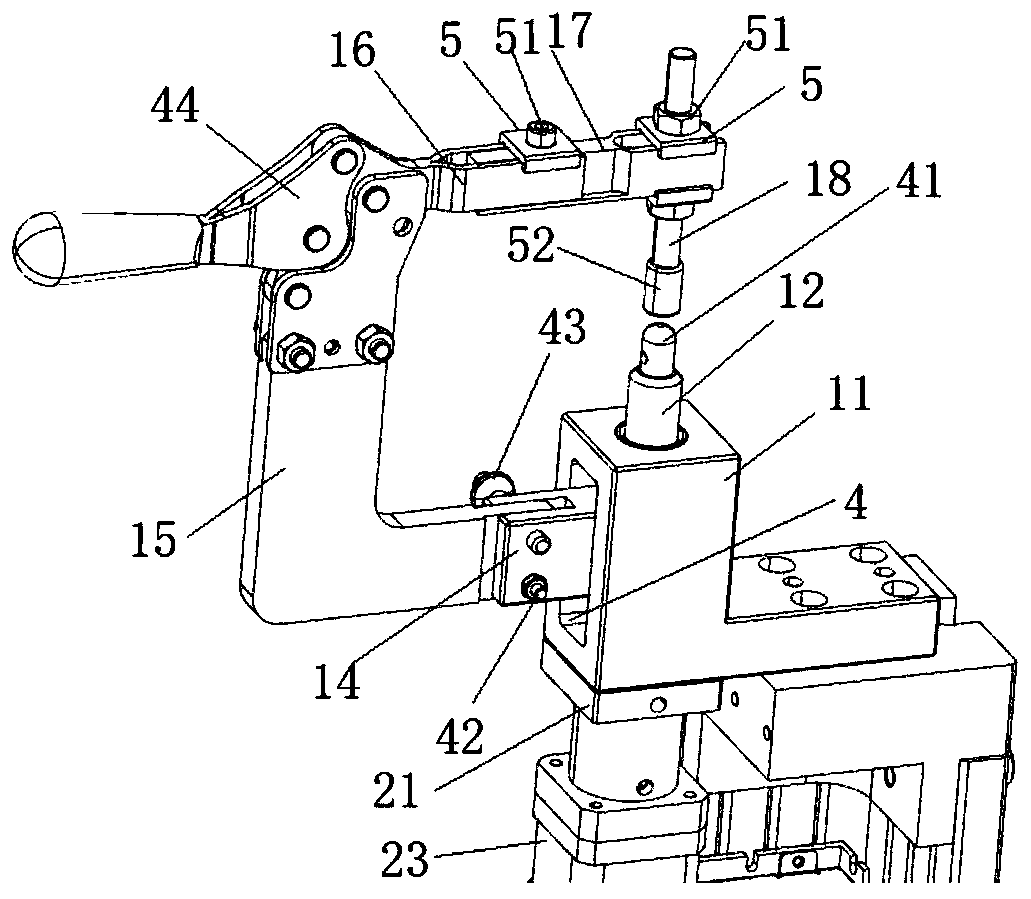

[0035] refer to Figure 1-3 As shown, this embodiment is an automatic adjustment device for checking fixture support, including a clamping mechanism 1 , an adjustment mechanism 2 connected to the clamping mechanism 1 , and a support device 3 connected to the adjustment mechanism 2 .

[0036] The support device 3 includes a support frame 31 and a number of fast locking parts arranged at the bottom of the support frame 31. The quick locking parts fix the support frame 31 on a welding tool platform (not shown in the figure) or a coordinate measuring machine.

[0037] The quick locking member includes a knob 32 placed on the bottom surface of the support frame 31 , which is screwed into and passes through a threaded portion of the support frame 31 (not shown in the figure).

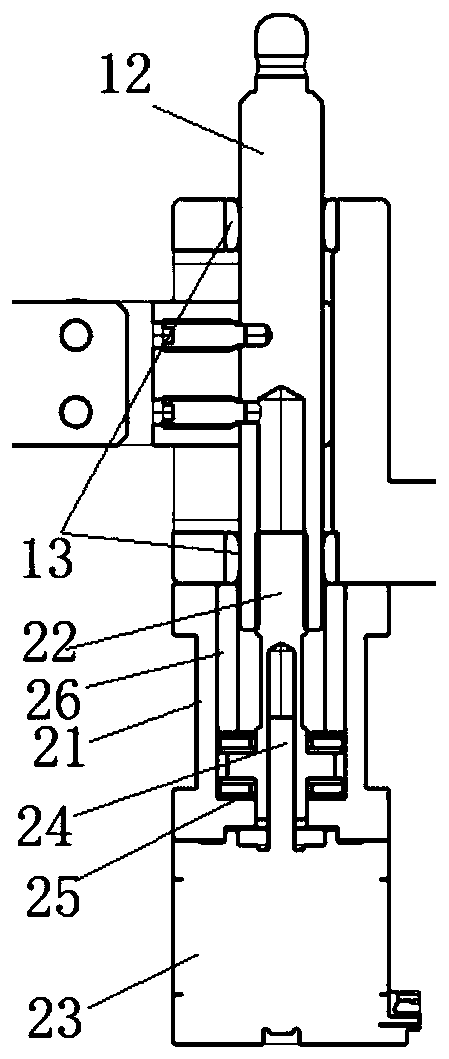

[0038] The clamping mechanism 1 includes a fixing base 11 arranged on the top of the supporting frame 31 , a guide shaft 12 passing through the fixing base 11 , and a clamp assembly sleeved on the outside of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com